Charge management system for rechargeable forklift, and charge management method

A charging management and recharging technology, applied in secondary battery charging/discharging, charging stations, electric vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

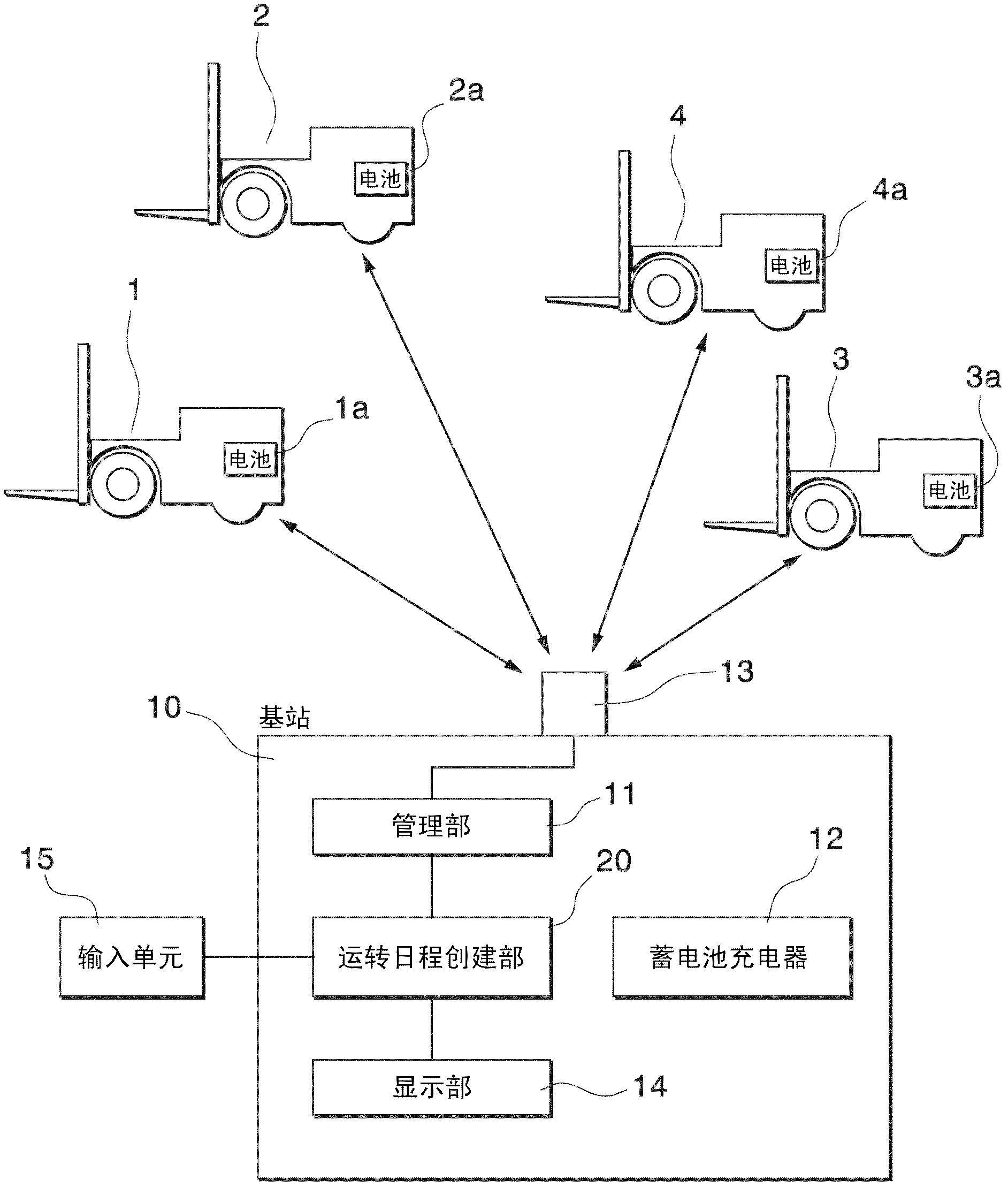

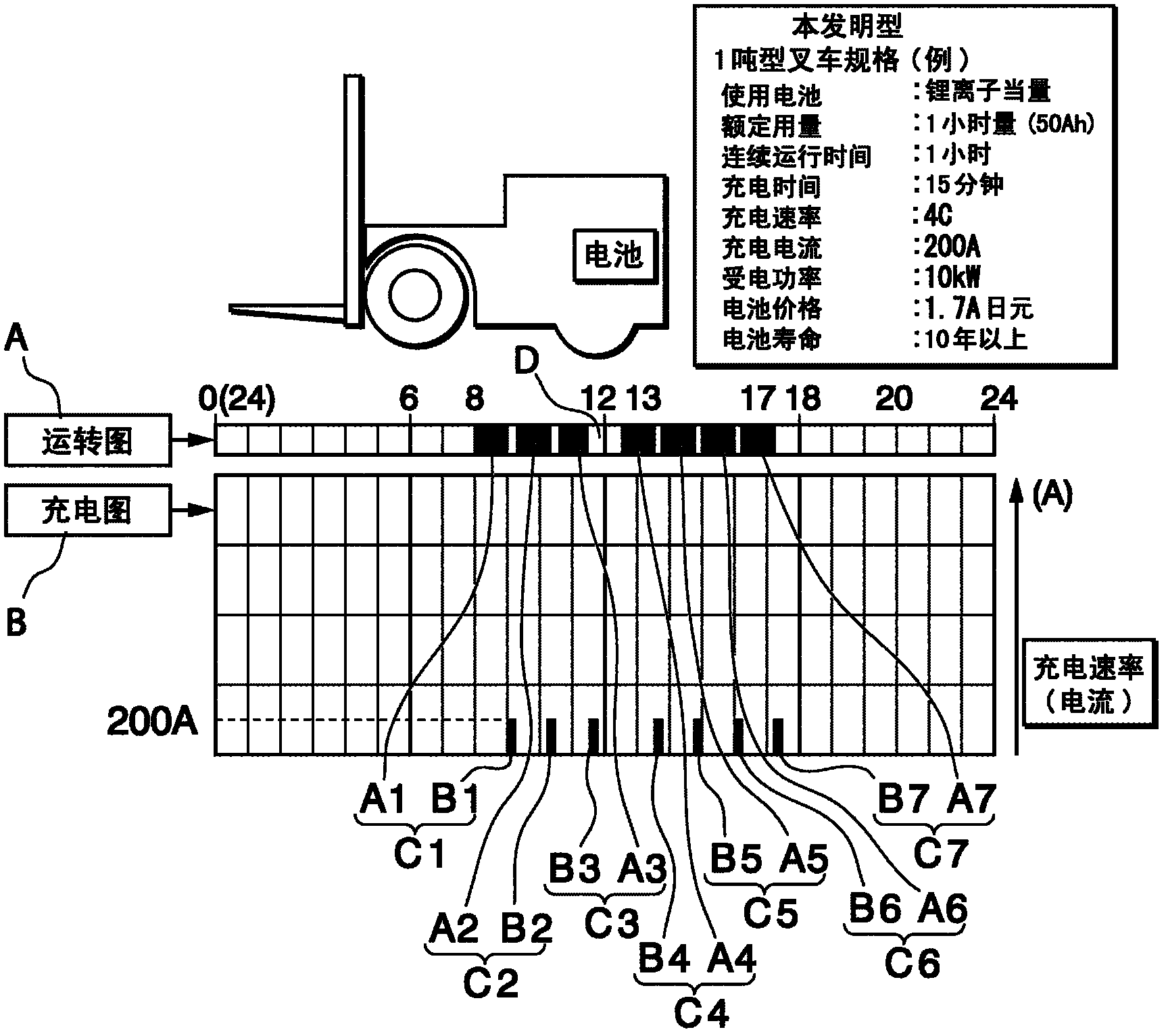

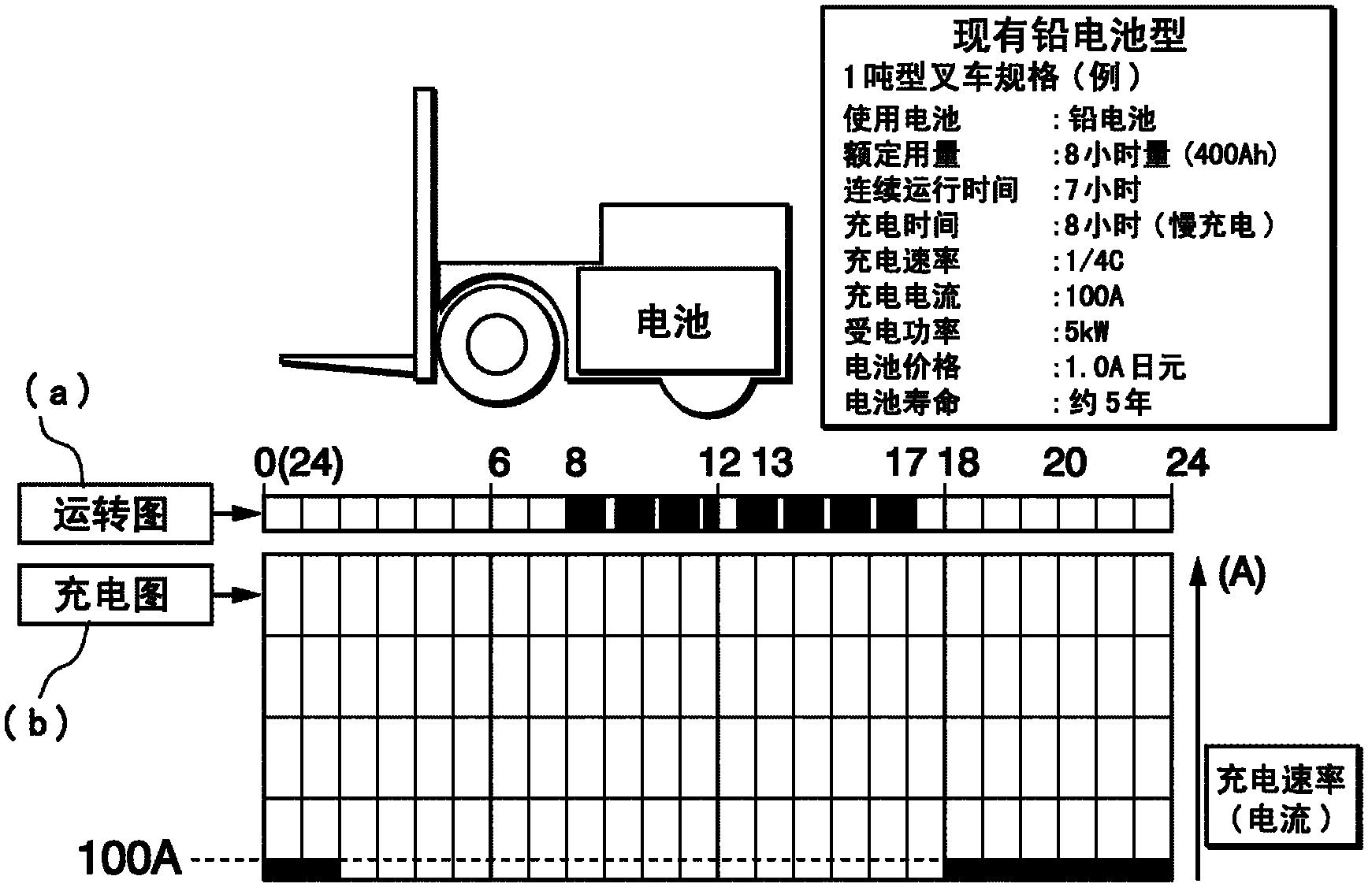

[0037] refer to figure 1 as well as figure 2 An embodiment of the present invention will be described.

[0038] figure 1 It is an overall view of the charging management system for a cordless forklift according to this embodiment. Four forklifts (shown as forklift 1, forklift 2, forklift 3, and forklift 4 in the figure) are used, and each of the forklifts 1 to 4 is equipped with There are small lithium ion batteries 1a to 4a capable of rapid charging as secondary batteries.

[0039]On the other hand, a base station 10 is installed in the work area of these forklifts 1 to 4 . The base station 10 is provided with an operation schedule creation unit 20 for creating an operation schedule, which is a charging schedule for the forklifts 1 to 4, and outputs a return command / departure to the forklifts 1 to 4 according to the operation schedule created by the operation schedule creation unit 20. A management unit 11 for commands and the like; a battery charger 12 for charging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com