Correcting mechanism for T-shaped steel panel of bridge

A T-shaped steel and panel technology, applied in the field of machinery and equipment, can solve the problems of high labor intensity, low production efficiency, and difficult operation of workers, and achieve the effects of simple structure, improved production efficiency, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

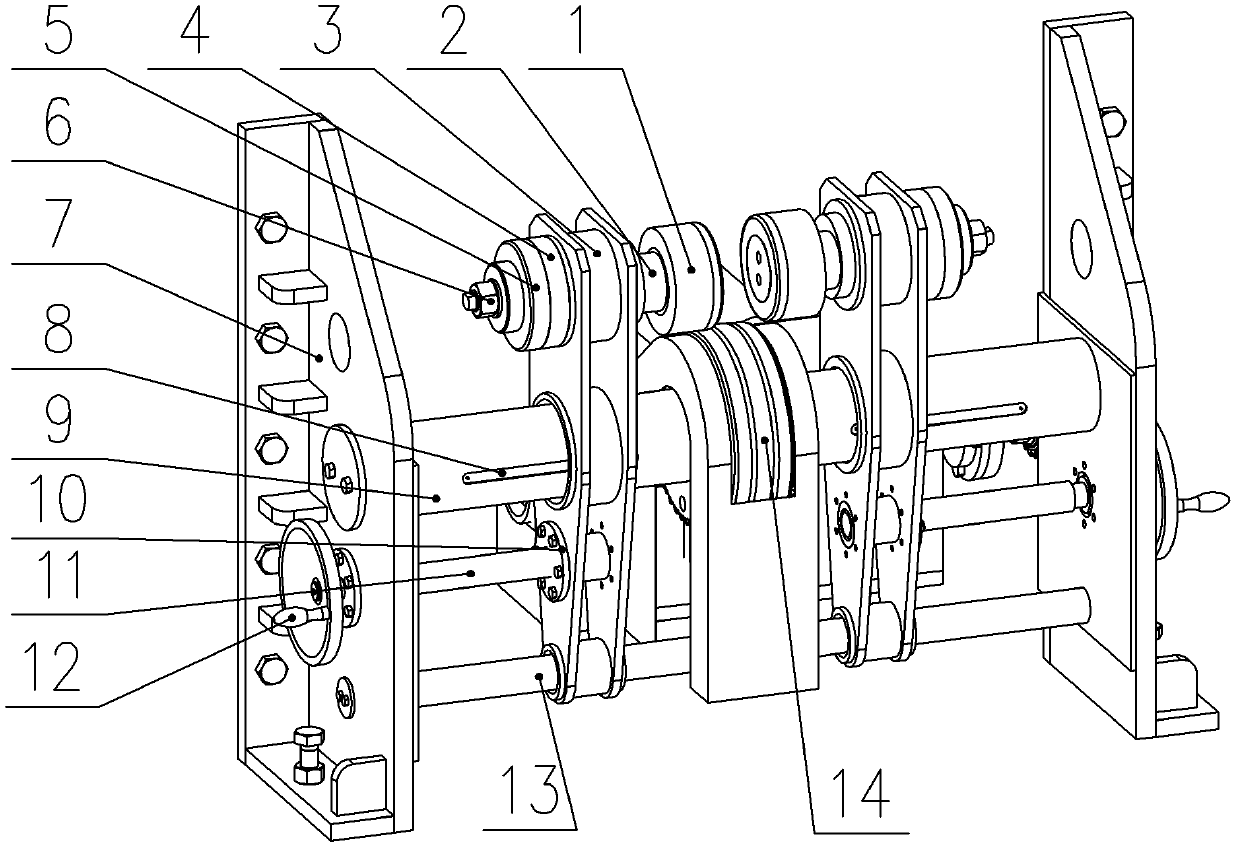

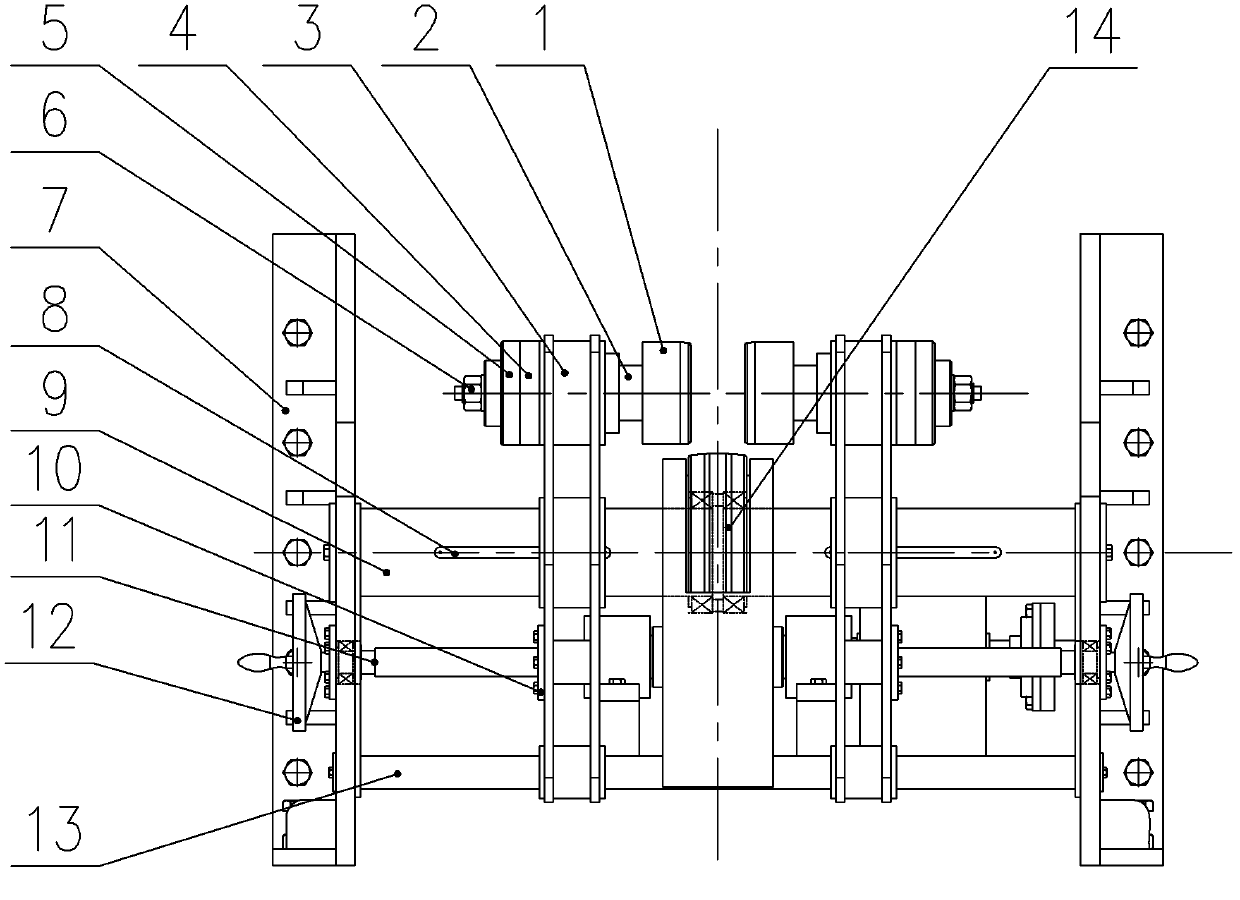

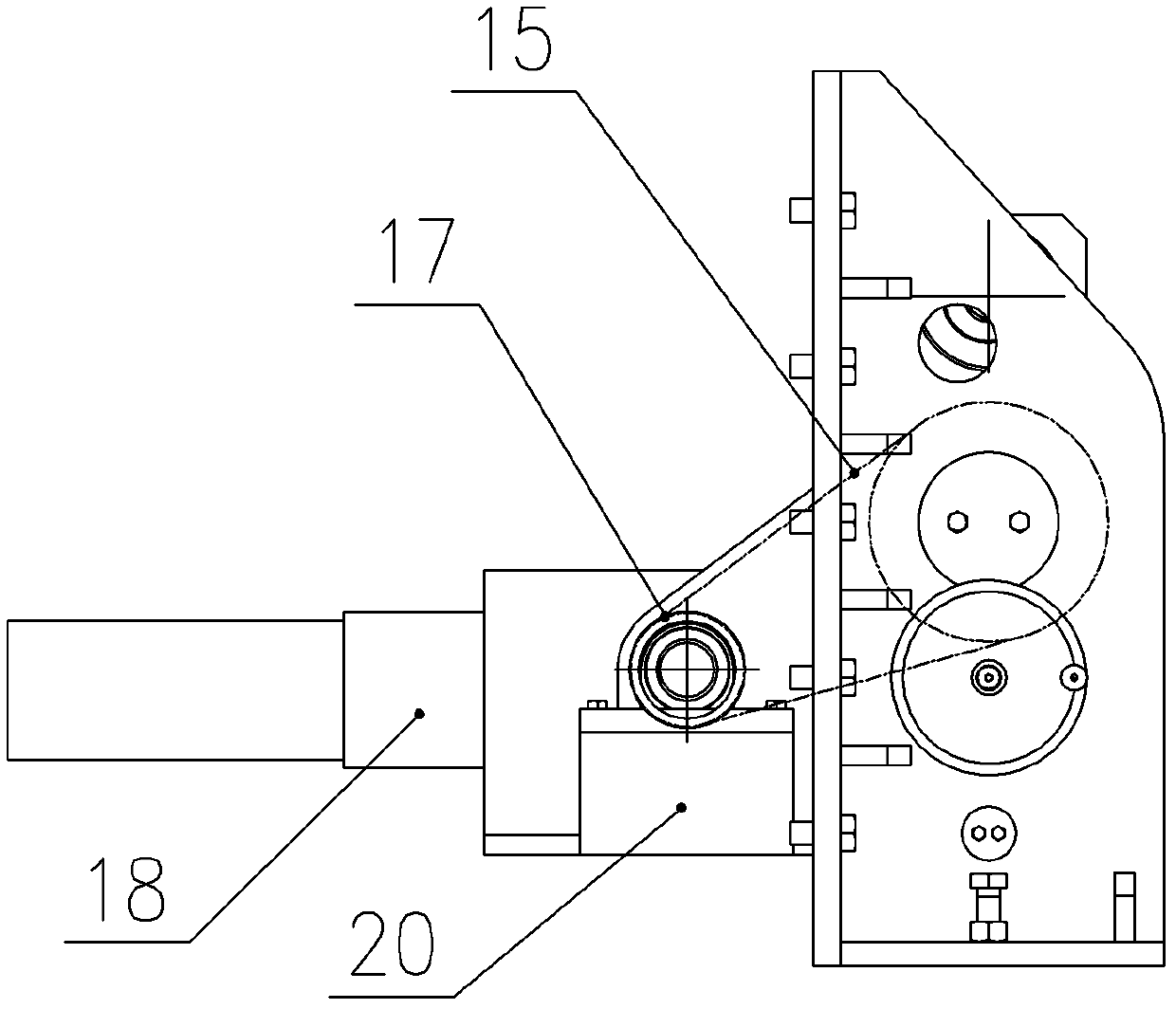

[0016] As shown in the figure: the bridge T-shaped steel panel correction mechanism in the embodiment is mainly composed of a correction wheel 1, a correction shaft 2, a support 3, a fixed toothed disc 4, a rotating toothed disc 5, a lock nut 6, a stressed support 7, and a scale 8. Large guide shaft 9, screw nut 10, screw rod 11, hand wheel 12, guide shaft 13, drive wheel 14, drive chain 15, large sprocket 16, small sprocket 17, reducer 18, drive shaft 19, bearing Seat 20 and other components are formed.

[0017] Such as Figure 1~Figure 4 As shown, two stressed supports 7 are arranged on both sides, and a large guide shaft 9 and a small guide shaft 13 are installed on the two stressed supports 7, and a drive is installed on the described large guide shaft 9 through a bearing. Wheel 14, the drive wheel 14 is driven to rotate by a drive mechanism; two axially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com