Steel rope lifting gripper for checking elevator speed limiter

A technology of elevator speed limiter and steel wire rope, which is applied in the direction of elevator, transportation and packaging, etc. It can solve the problems of clamping failure, too small, and difficult to control the lifting height of the wire rope, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

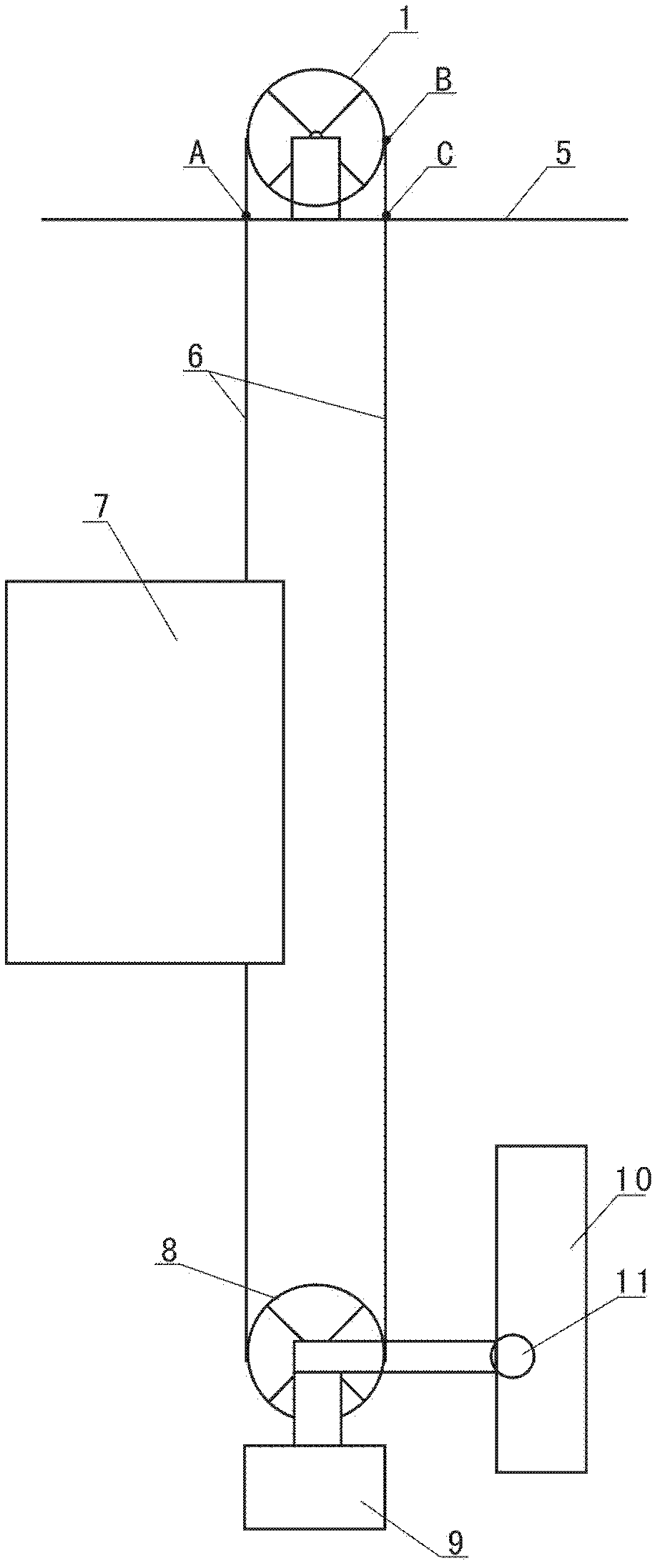

[0036] Such asfigure 1 As shown, the speed governor 1 of the elevator is placed above the ground 5 in the elevator machine room. The diameter of the steel wire rope 6 used for the speed governor 1 is generally 8mm, and one end is connected to the safety gear on the car 7 of the elevator. 8. Fix it upwards on the car 7, and the car 7 drives the wire rope 6 to move, so that the speed limiter 1 in the elevator machine room and the tension pulley 8 in the elevator pit rotate together. The lower end of the tensioning wheel 8 is equipped with a weight 9, and the tensioning wheel 8 is installed on the fixing device 10 and can rotate in a small range with the connection end 11 as the center of a circle, so that the tensioning wheel 8 can move about 10 cm in the up and down direction. distance. figure 1 Point A and point C are the junctions between the wire rope 6 and the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com