An automatic shaping machine for powder metallurgy products

A powder metallurgy and shaping machine technology, applied in the field of powder shaping, can solve the problems of unable to complete the shaping action and shaping action at the same time, lack of automatic shaping machine, etc., to achieve simple and fast processing methods, improve product quality and work efficiency, and smooth the movement process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In the embodiments, parts of the same configuration are given the same reference numerals and descriptions are omitted.

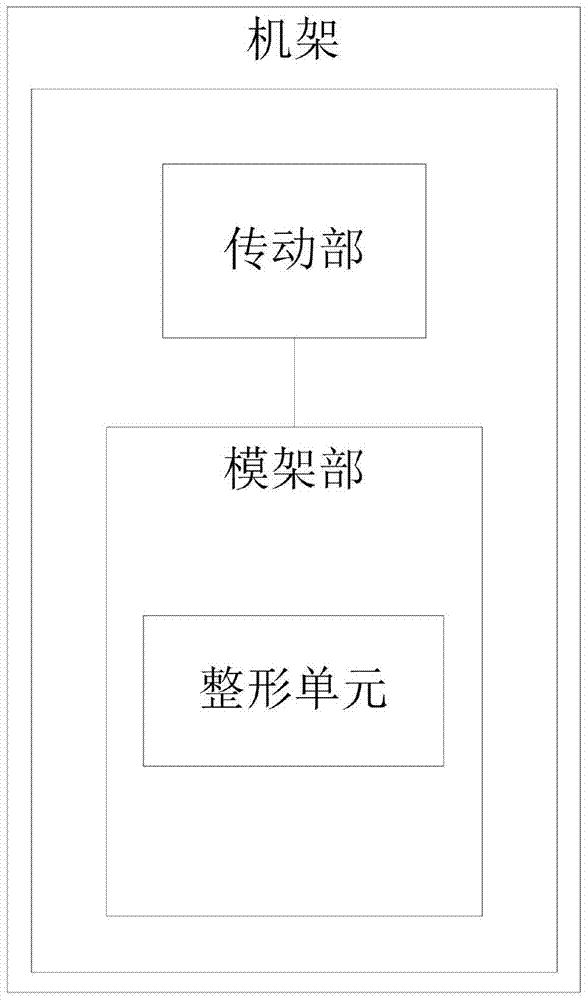

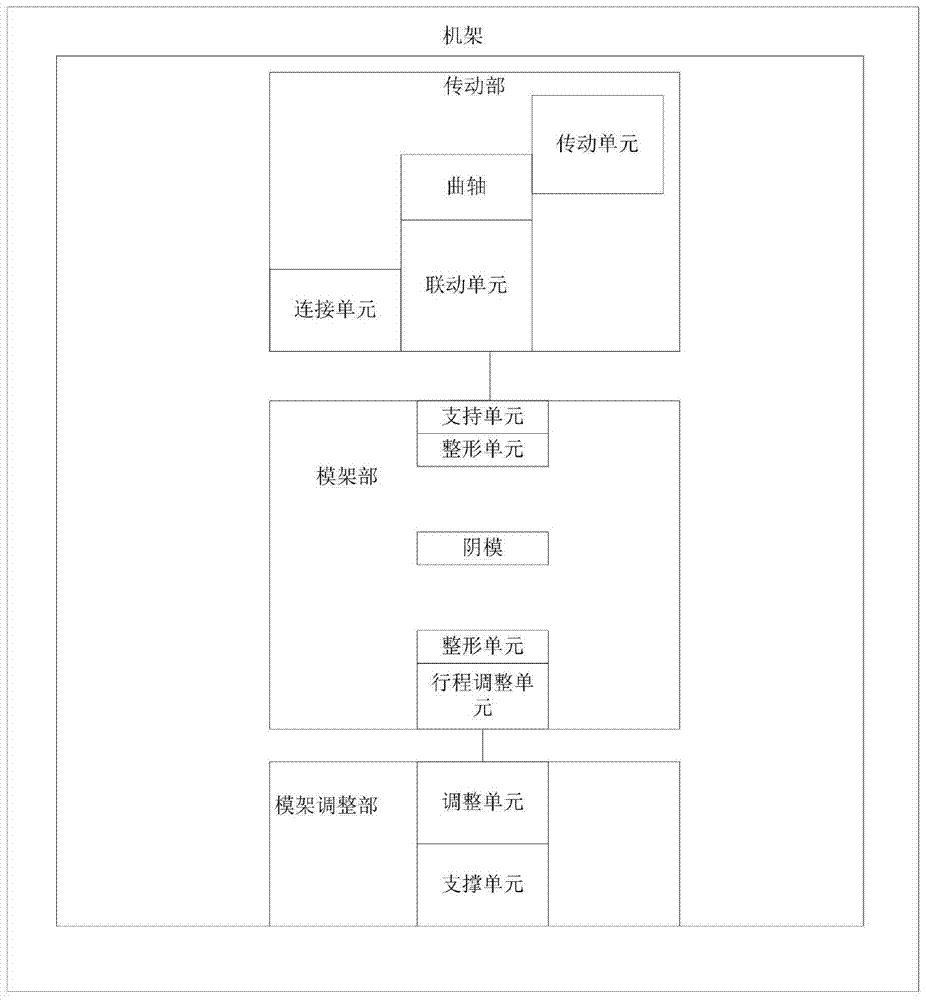

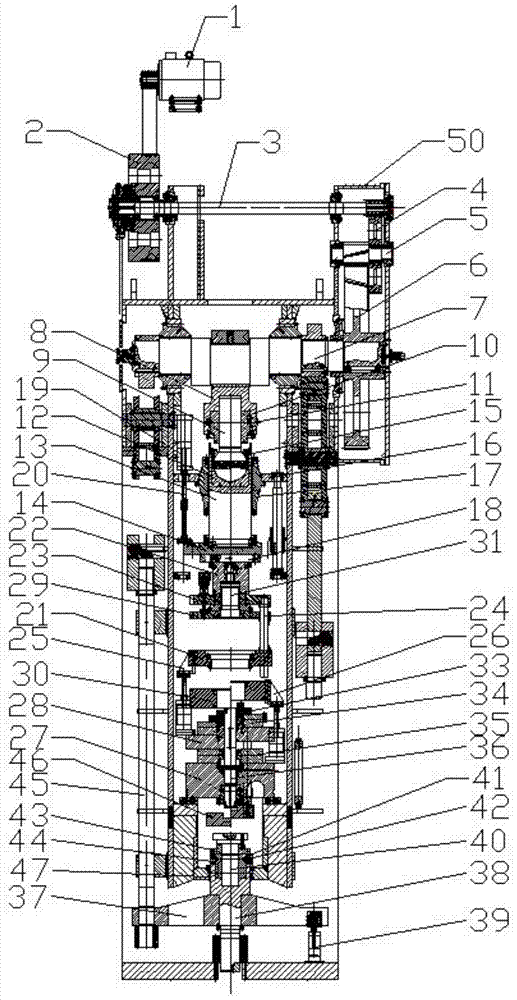

[0046] refer to figure 1 Shown is the basic functional block diagram of the powder metallurgy product automatic shaping machine of the present invention; figure 2 , is a structural and functional block diagram of the powder metallurgy product automatic shaping machine of the present invention; and image 3, is a schematic cross-sectional view of the overall structure of the automatic shaping machine for powder metallurgy products of the present invention; The frame 50 is fixedly arranged on the upper part of the automatic shaping machine for generating working power and transmitting it to the formwork part; the formwork part is fixedly arranged inside the automatic shaper through the frame 50 , used to receive the power transmitted by the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com