Torque units and devices and applications in the manufacture of garments

A technology of torsion and car covering, applied in the direction of transportation and packaging, vehicle parts, removable outer sheath, etc., can solve problems such as troublesome and difficult storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment provides a torsion unit, as attached Figure 4 As shown, the elastic material 1 and the connection structure 2 are used to make the shape, and the elastic material is twisted into a shape similar to "8", and the "8" shape is overlapped with the connection structure so that it is located in the connection structure The stacked elastic material parts have movable gaps between each other.

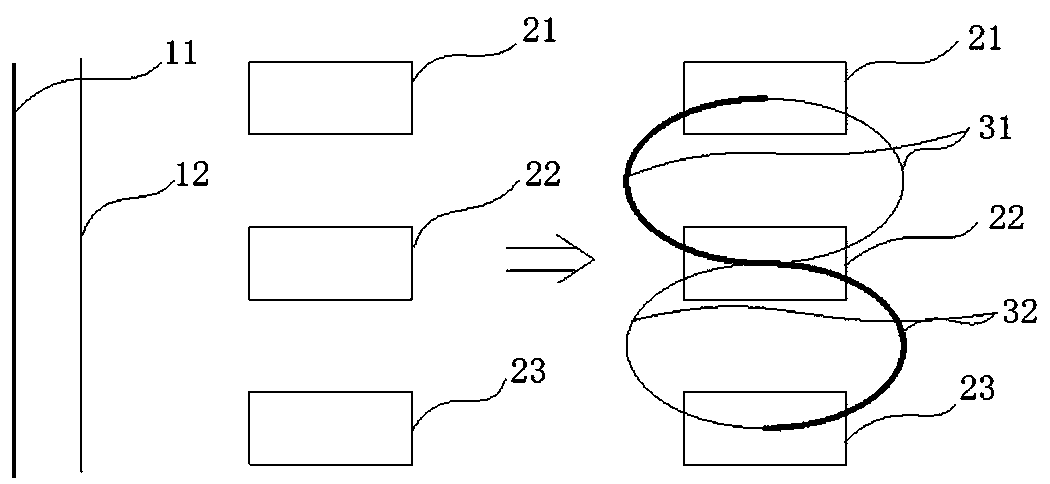

[0072] The present embodiment adopts two elastic materials to make. The molding process is attached figure 1 As shown, there are two elastic materials, that is, the first elastic material 11 and the second elastic material 12, and one end of the first elastic material 11 and the second elastic material 12 are connected, and the position of the connection here can be adopted The connection may be carried out by means of welding, or a connection structure 21 may be used for connection, and the respective one ends of the first elastic material 11 and the second elastic ma...

Embodiment 2

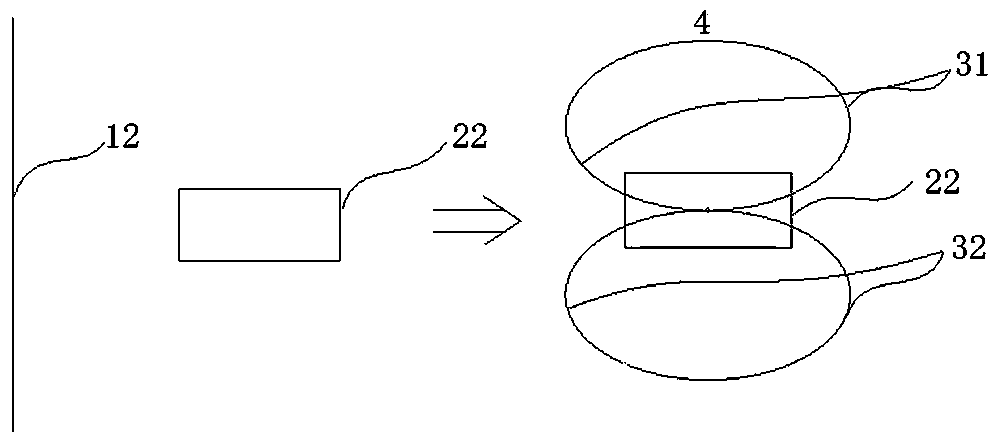

[0081] This embodiment provides a torsion unit, other methods and structures are the same as those in embodiment 1, the difference is that the torsion unit in this embodiment can only be made of a piece of elastic material, as shown in the attached figure 2 As shown, one end of the elastic material 12 is twisted into a part of the first twisted ring 32 after passing through the connection structure 22 from the beginning to the end, and then passes through the connecting structure 22 from the beginning to the end to form a complete first twisted ring 32; After penetrating through the connecting structure 22 , it connects with the other end of the elastic material 12 at position 4 to form a second twisted loop 31 . The joining method can adopt the way of welding or connecting structure. If the connection structure is adopted, reference may be made to Embodiment 1.

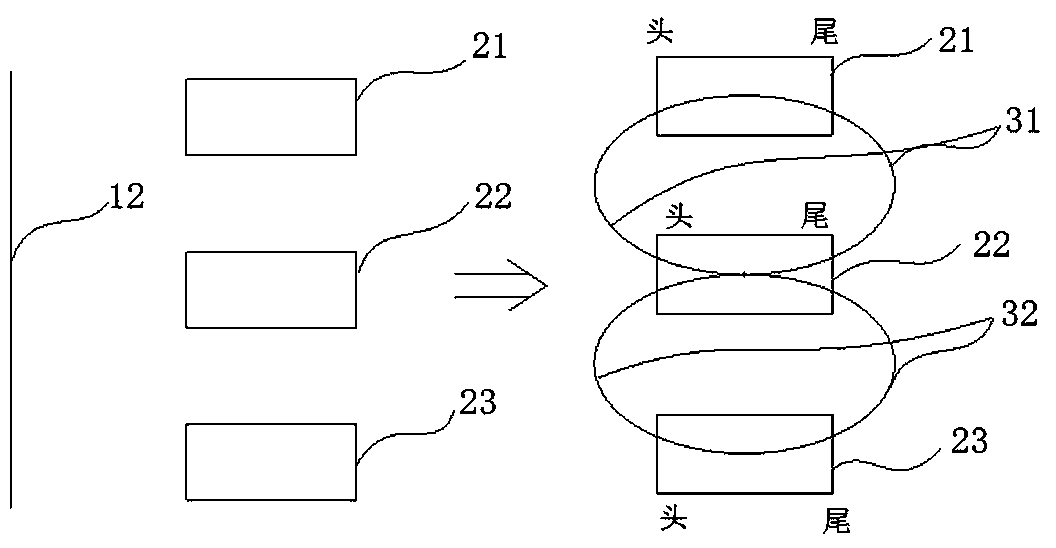

[0082] as attached image 3 As shown, when a strip of elastic material is used for molding in this embodiment, ...

Embodiment 3

[0085] This embodiment can further provide a torsion device provided with the torsion unit, and the torsion device is obtained by connecting more than two torsion units. The connection of the two or more torsion units may be a transverse connection, and different torsion units are connected through connecting pieces. Preferably, the connecting member is a torsion spring.

[0086] The connection of the two or more torsion units may be longitudinal connection, no matter it is the aforementioned embodiment 1 or embodiment 2, there are more than two connection structures.

[0087] Based on Example 2, if there are three connection structures, then the longitudinal connection method is that one end of the elastic material penetrates from the first connection structure from head to tail and then from the second connection structure from tail to head , then penetrate from head to tail from the third connection structure, then penetrate from head to tail from the second connection str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com