Leveling mechanism for engineering machinery

A technology of leveling mechanism and construction machinery, applied in cranes and other directions, can solve the problems of difficulty in retracting and placing objects, easy derailment of vehicles, inability to rotate double-arm cranes, etc., and achieves the effect of high work efficiency and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

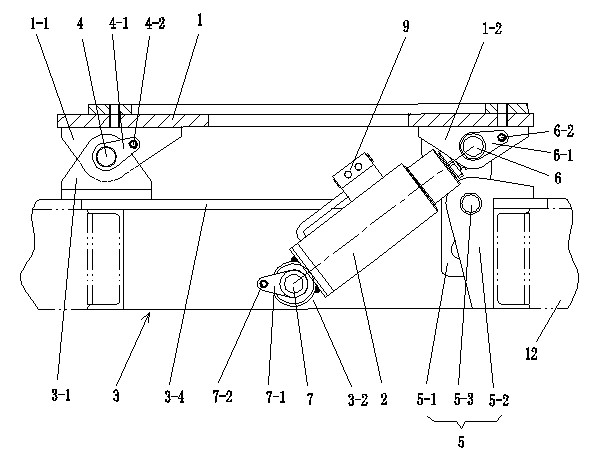

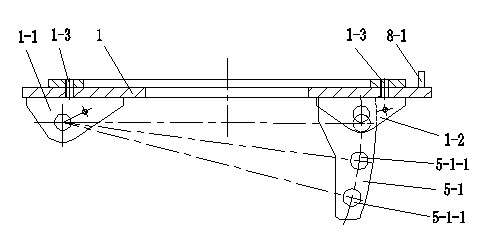

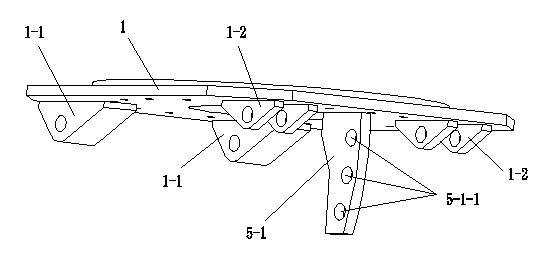

[0026] like Figure 1~6 As shown, a leveling mechanism for engineering machinery of the present invention includes a leveling turntable 1, a leveling cylinder 2, a leveling cylinder support frame 3 and an adjustable position locking device 5, and the leveling turntable 1 is located on the leveling cylinder On the support frame 3 and hinged with the leveling cylinder support frame 3, one end of the leveling cylinder 2 is hinged with the leveling turntable 1, and the other end is hinged with the leveling cylinder support frame 3, and the adjustable position locking device 5 is connected to the leveling turntable 1 and the leveling cylinder support frame 3.

[0027] like figure 1 , 2 , 3, 4, and 5, the lower part of the leveling turntable 1 has a fixed hinged ear seat 1-1 and an oil cylinder hinged ear seat 1-2, and the leveling oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com