Spinning machine with compact equipment

A technology of spinning machine and equipment, applied in the field of spinning machine with compact equipment, can solve the problem that the moving cylinder fan cannot be eliminated, and achieve the effect of simplifying improvement and simplifying assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

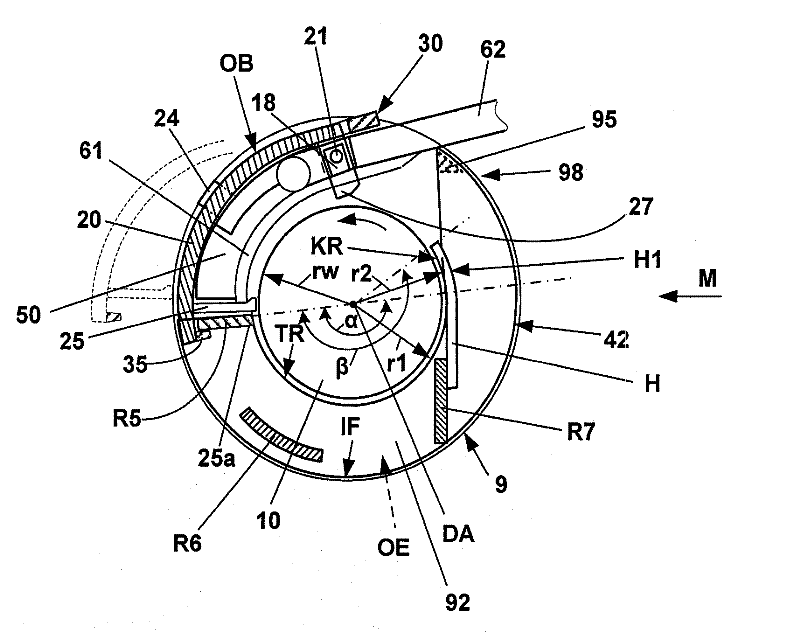

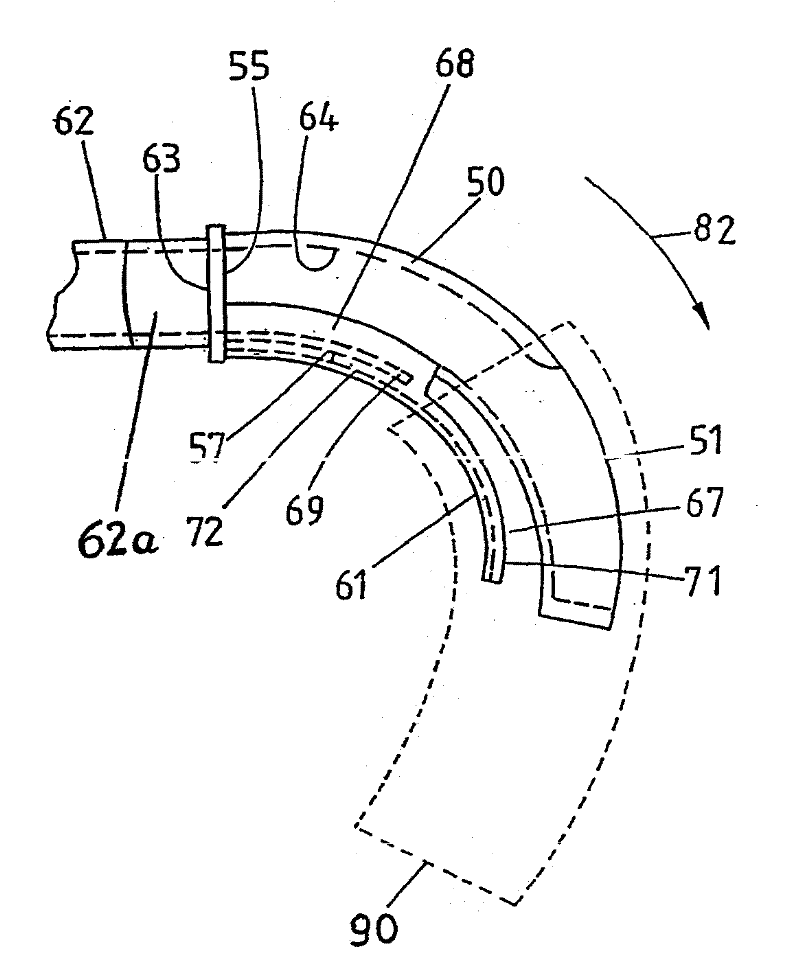

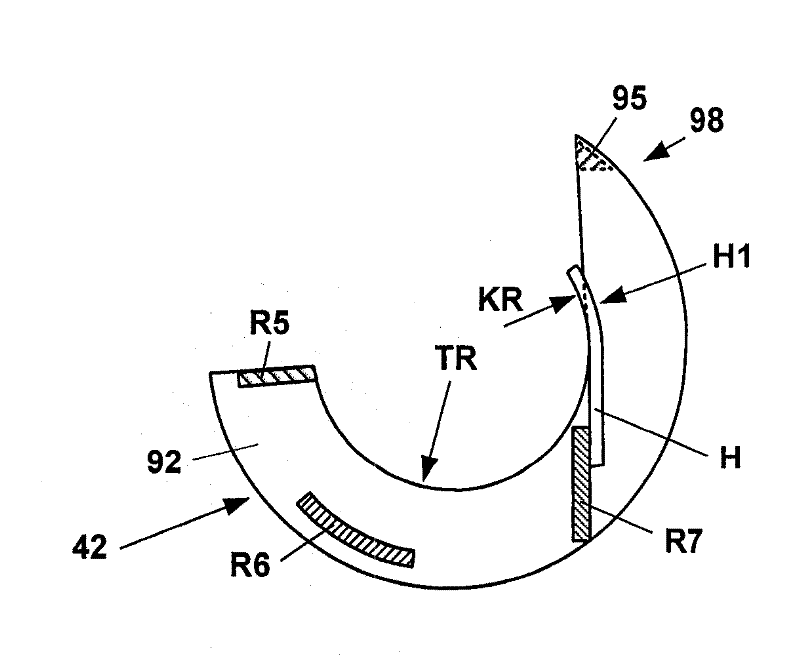

[0029] figure 1 represents a drafting system unit 1 (of a plurality of drafting system devices arranged next to each other) of a not shown spinning machine (for example, a ring spinning machine), wherein in this example the drafting system unit consists of three pairs Rolla poses. These are formed by the incoming roller pair 2,3 followed by the central roller pair 5,6. The preparation yarn F (roving) drawn off from a roving drum not shown is conveyed to the drafting system unit 1 by means of intake rollers 2 , 3 . When compared to the twisting speed of the introduction rollers 2, 3, the twisting speed of the center rollers 5, 6 is slightly increased, so that an untwisting draft of the roving F is produced between this pair of rollers. Small conveyor belts 11 , 12 are in each case guided around central rollers 5 , 6 which are held in position where they are shown around rollers not shown in any detail. After leaving the nip line Z1 between the central rollers 5 , 6 , the unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com