Anti-bending, zero-temperature-difference and fireproof novel hiddenly spun thermal energy cloth

A new type of anti-bending technology, applied in textiles, textiles and papermaking, fabrics with resilience, etc., can solve the problems of poor 360-degree bending resistance, poor comfort performance, poor safety performance, etc., and reach the service life Long, improved bending resistance, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

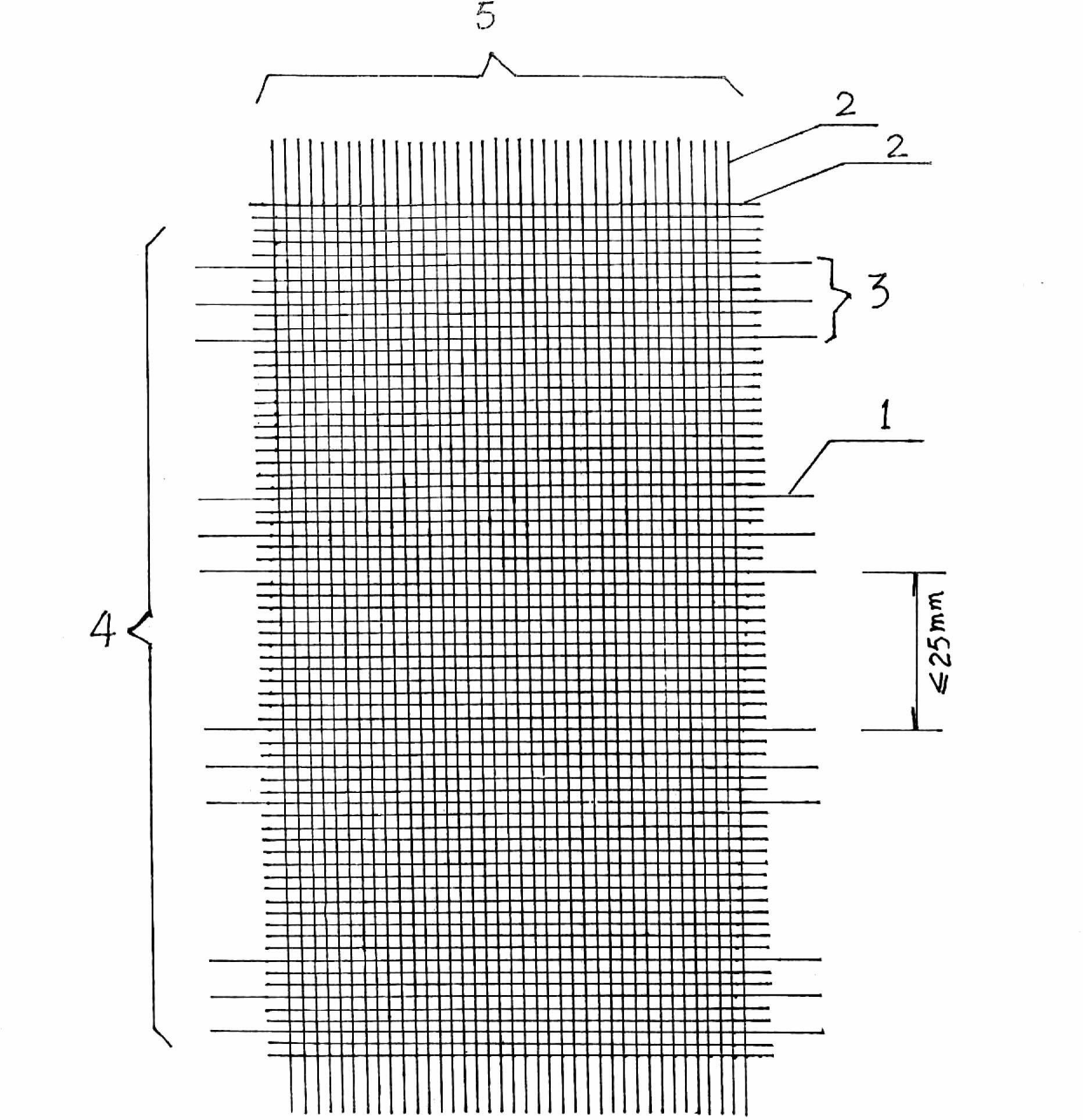

[0026] see figure 1 Each group of heating yarn groups 3 is evenly and equidistantly distributed in the ordinary yarn 2 at a distance of less than 25mm, and together they are used as the warp yarn 4 of the fabric, and then the warp yarn 4 and the weft yarn 5 are interwoven for weaving to become the new hidden spinning heat energy of the present invention. cloth. The weft yarns 5 consist entirely of normal yarns 2 . The heating yarn 1 in the warp yarn 4 is the heating unit hidden between the fabrics of the new hidden spinning thermal energy fabric.

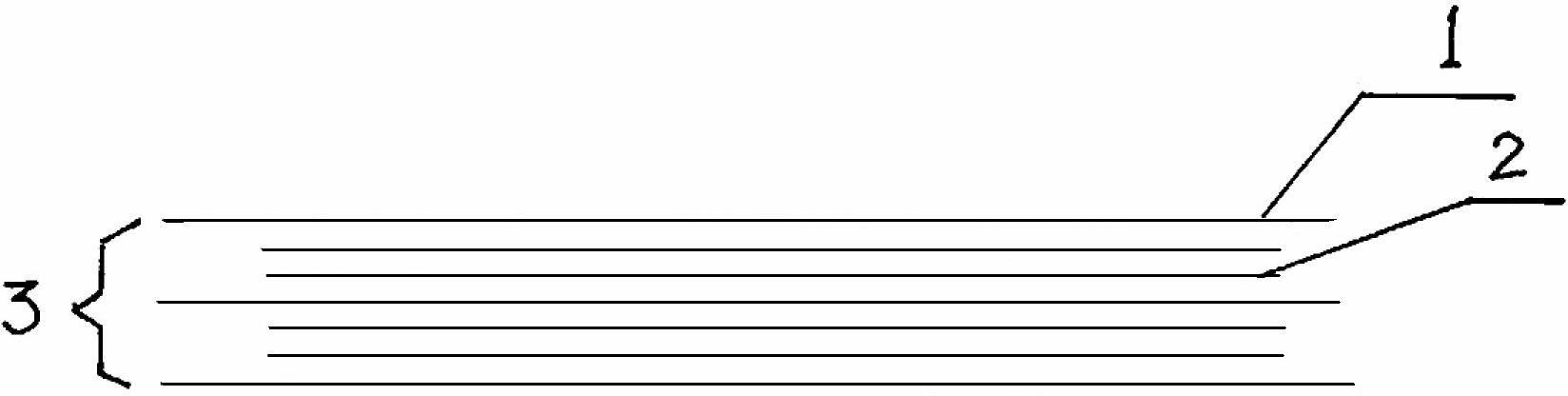

[0027] see figure 2 In the present invention, a plurality of heating yarns 1 are arranged side by side as a group, and two to five common yarns 2 are spaced between each heating yarn in each group of heating yarns in a parallel manner to form a heating yarn group 3 .

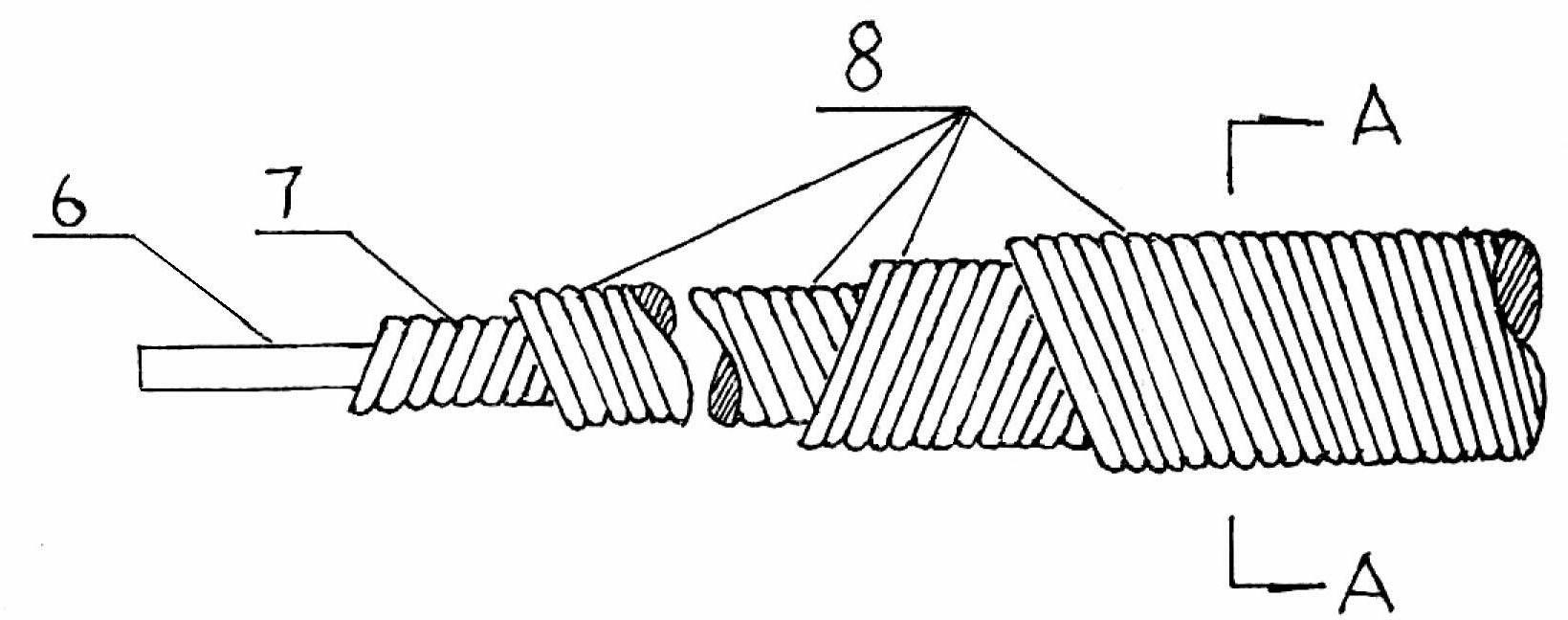

[0028] see image 3 , Figure 4 , the structure of the above-mentioned heating yarn 1 is: the center uses 50D polyester filament 6 as the elastic yarn core, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com