An ultra-fine wire drawing die elongation testing device

A wire-drawing die and testing device technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low efficiency of ultra-fine lines, high reading errors, discounts on production efficiency and work efficiency, etc., to ensure one machine The effect of versatility, production cost saving, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

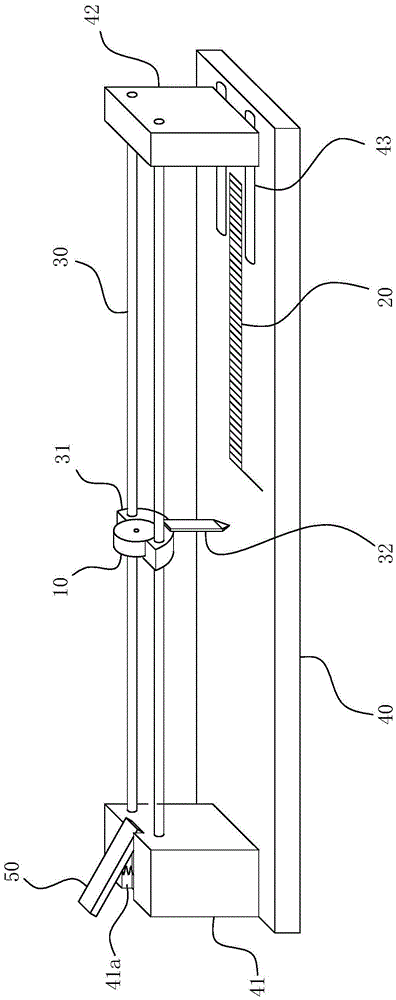

[0025] For ease of understanding, combined here Figure 1-2 Concrete structure of the present invention and working method thereof are described as follows:

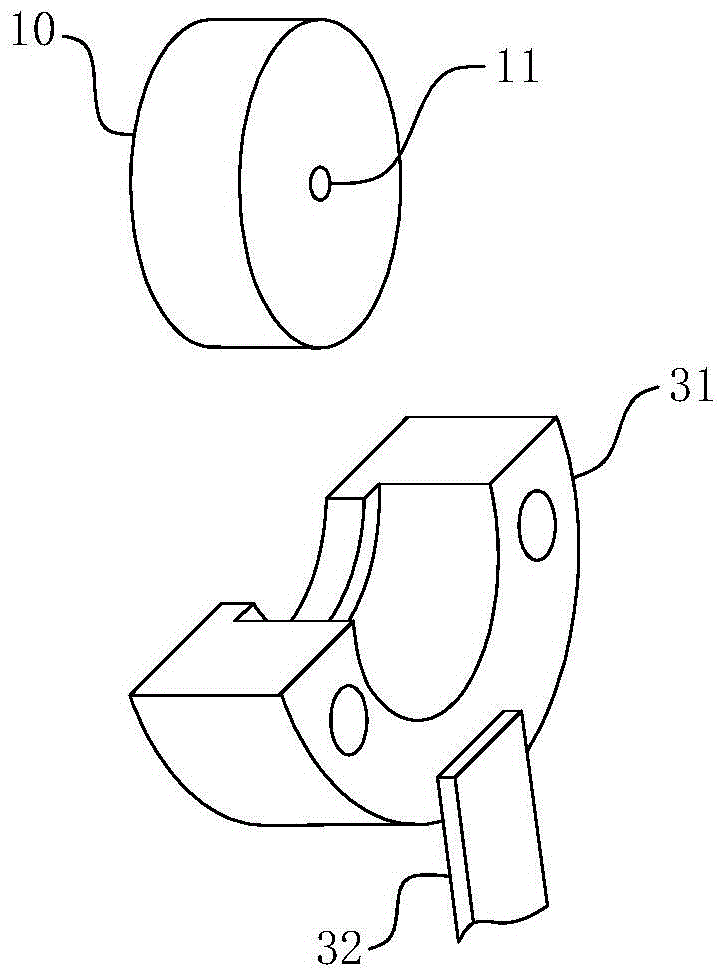

[0026] During the concrete operation of the present invention, as figure 1 As shown, it usually includes a square long plate-shaped base 40, and a first fixed platform 41 and a second fixed platform 42 are respectively arranged at both ends of the length direction of the base 40, and two parallel beams are arranged between the two fixed platforms. Guide rail 30, a slider part 31 that can move back and forth linearly along the guide rail 30 is erected on the guide rail 30. The slider part 31 is in the shape of a sleeve with an open upper part (also can be regarded as a "C" shape with a notch facing upwards) The inner cavity of the slider part 31 constitutes a fitting cavity for fitting and fixing the test mold 10 , and the structure of the test mold 10 can be firmly fitted in the slider part 31 and detachably matched wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com