Pull-type self-aligning hydraulic release bearing sub-pump unit

A technology of separating bearings and hydraulic sub-pumps, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of large transmission torque of the shifting fork, poor user comfort, and high impact noise, and achieve reliable operation, The effect of saving gearbox space and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

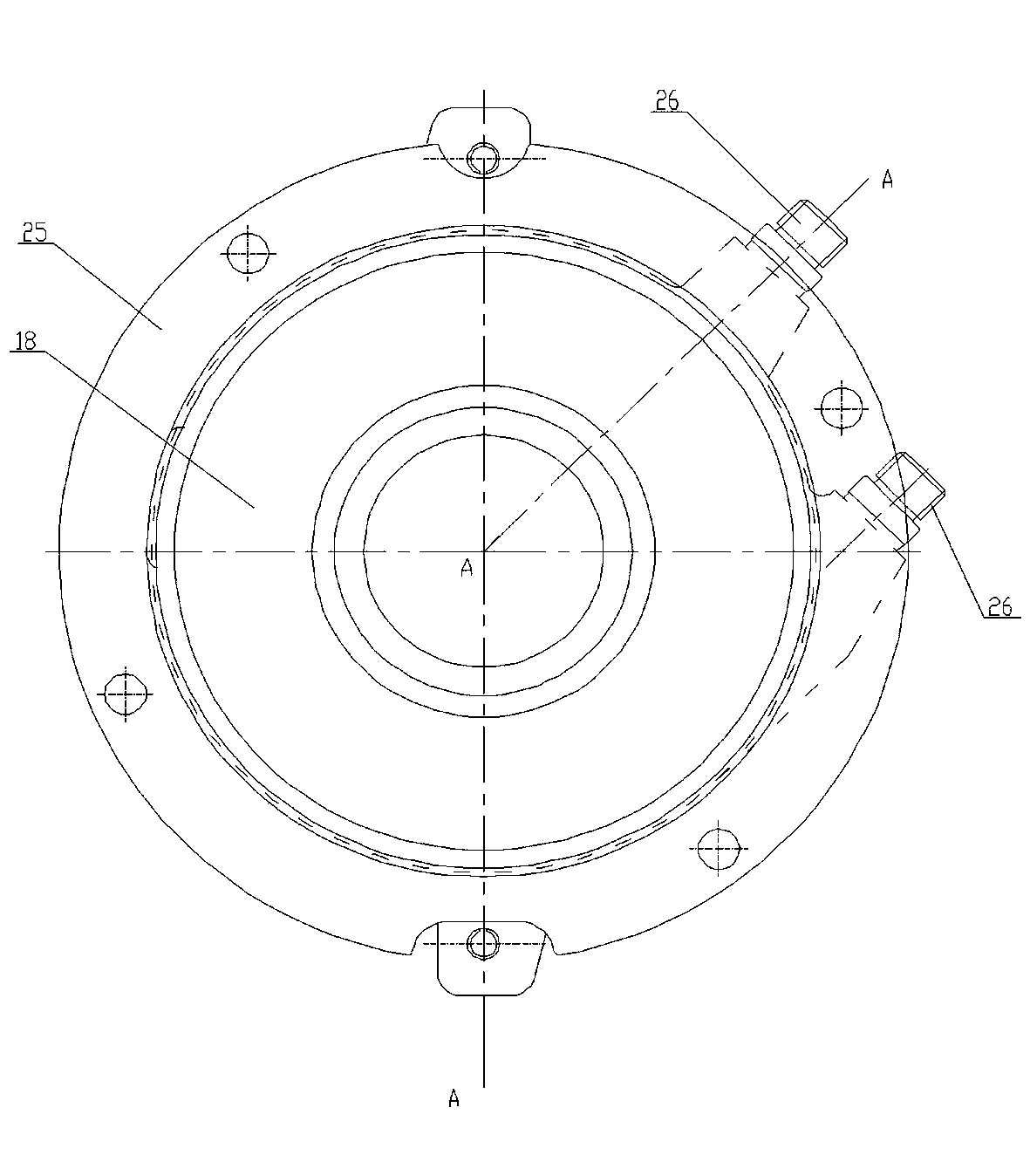

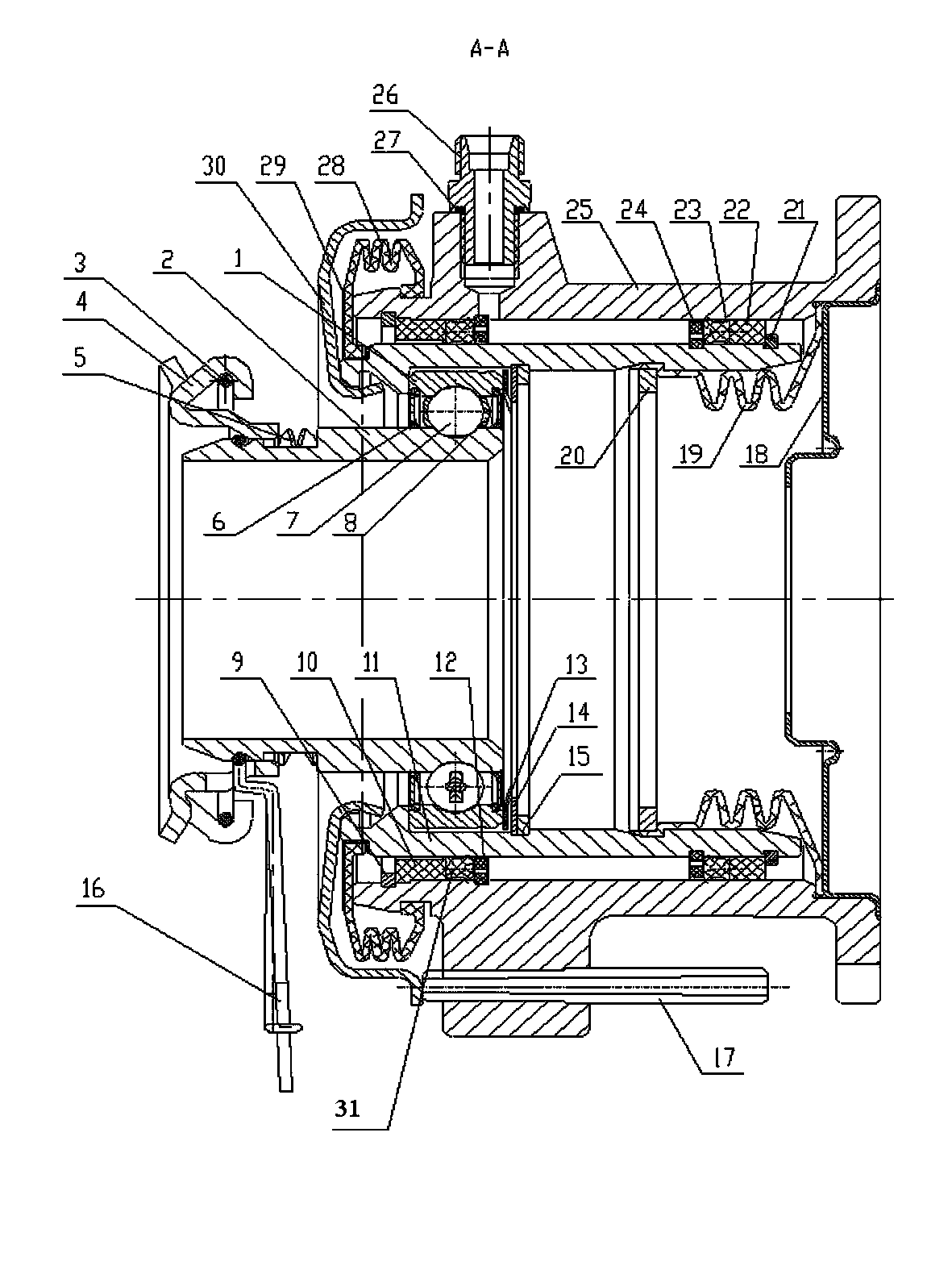

[0026] Refer to attached Figure 1~2 , the pull-type self-aligning hydraulic release bearing sub-cylinder unit includes an installation connection mechanism, an alignment mechanism, a bearing mechanism, a hydraulic sub-pump mechanism, a dust-proof mechanism and an auxiliary mechanism; the installation connection mechanism is composed of a clutch connection part and a gearbox connection part, Including separation pull ring 4, clamp 16, fixed ring 3 and helical compression spring 5; the centering mechanism includes self-aligning spring piece 13, self-aligning spring piece supporting ring 14 and self-aligning spring piece fixing ring 15, self-aligning spring piece It is the main part of the centering mechanism. The centering function is determined by the axial force generated after the part is compressed. The self-aligning spring fixing ring 15 and the self-aligning spring piece support ring 14 mainly play a fixed role; the bearing mechanism includes the outer Ring 1, inner ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com