Adjustable-type trolley for impact test

A crash test and adjustable technology, applied in the field of automobile crash test trolleys, can solve the problems of uneconomical time cost and money cost, unchangeable structure, and inability of trolleys to adapt to different sizes of car bodies, etc., to achieve simple structure and easy processing , the effect of maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

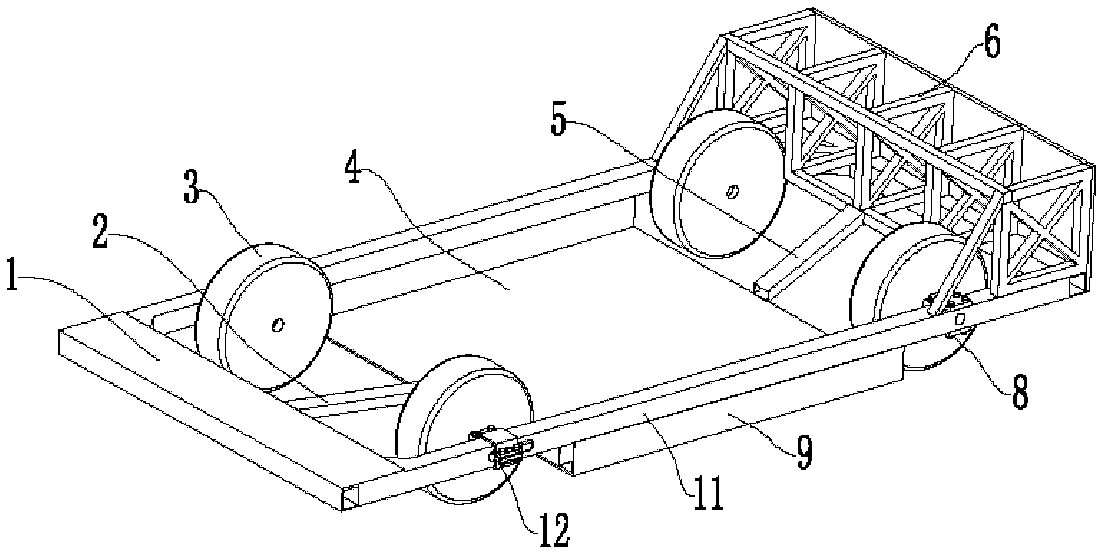

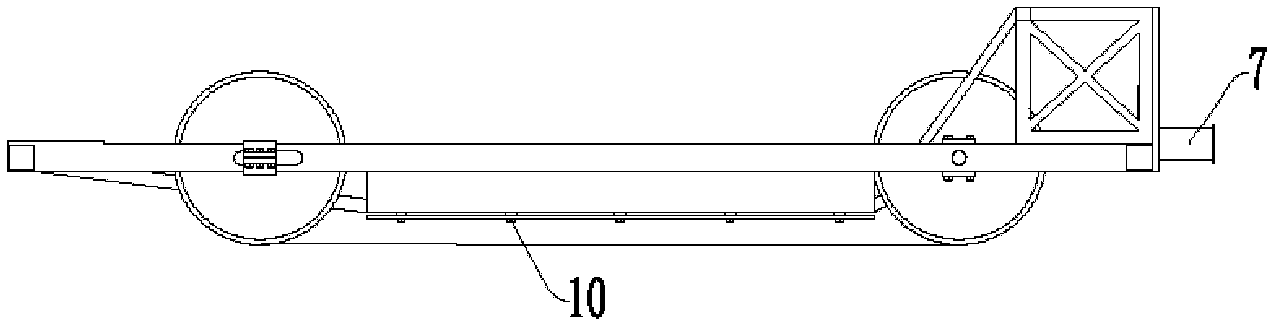

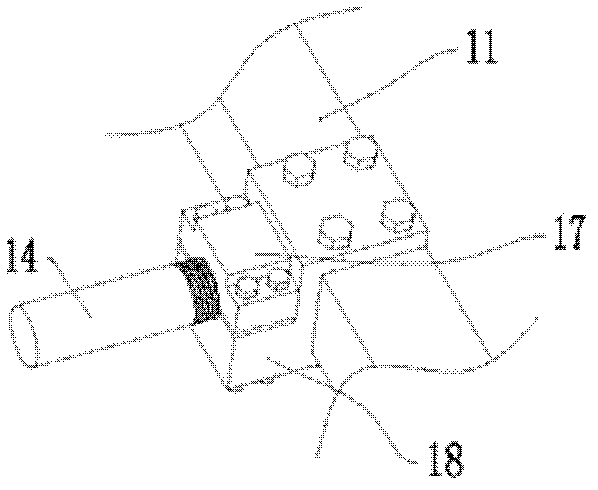

[0035] refer to figure 1 and figure 2 , The present embodiment includes a trolley frame 1, a front wheel track adjusting mechanism 8, a rear wheel track adjusting mechanism and a trolley wheelbase adjusting mechanism 12, and a floor height adjusting mechanism 10.

[0036] The trolley frame 1 includes a base plate 4, wheels 3, a rigid frame 6, a front longitudinal beam 5, a base plate connecting beam 9, side beams 11, a rear longitudinal beam 2, and an energy-absorbing cylinder 7. The bottom plate 4 is connected to the side beams 11 through the bottom plate connecting beam 9 . The front end of the front longitudinal beam 5 is connected with the rigid frame 6, and the two sides of the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com