Moment load simulator

A technology of load simulators and simulators, which is applied in the direction of instruments, machine/structural parts testing, and measuring devices, etc., can solve the problems of limited rotation angle range of small torque load simulators, large loading errors, etc., and achieve easy implementation and loading way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

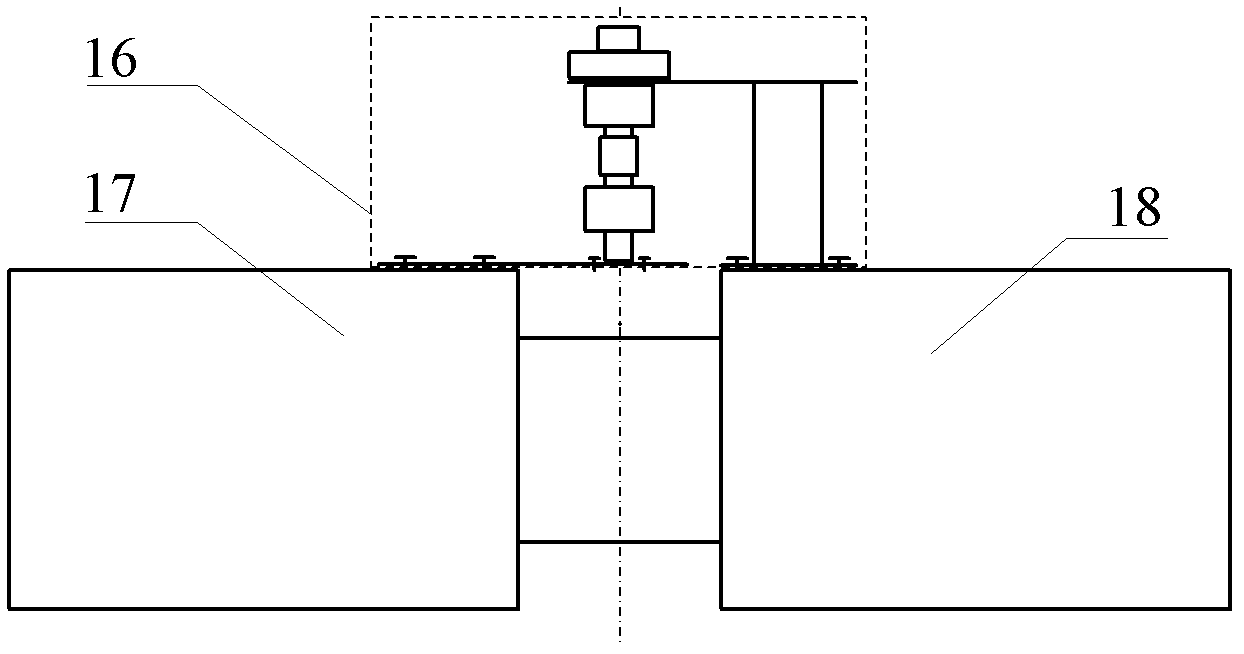

[0026] The present invention applies moment loading to the rotating shafts of the two expansion plates with relative rotation relationship, and the two fixed bottom plates of the invention are respectively connected to the sides of the inner expansion plate and the outer expansion plate.

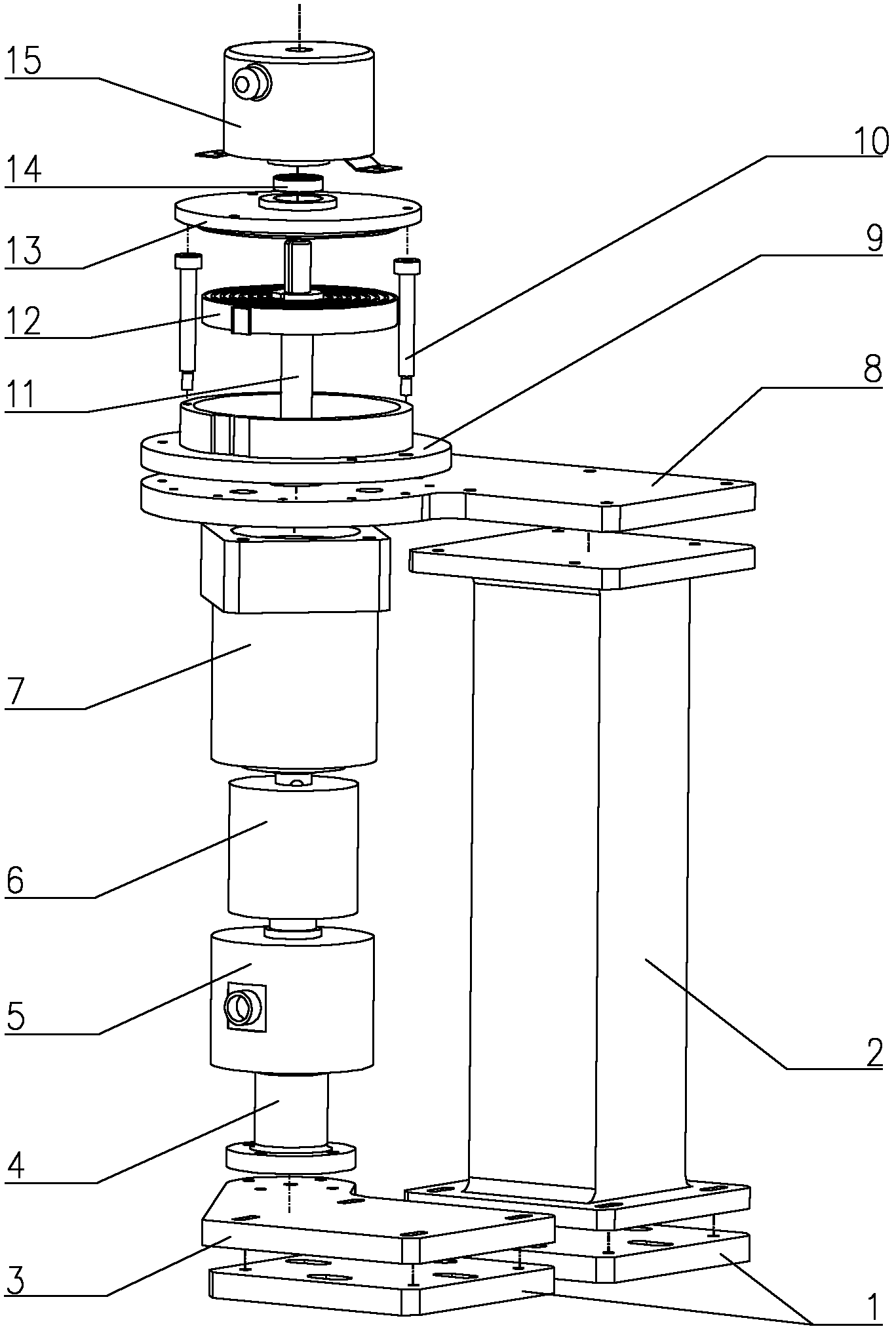

[0027] The composition of the moment load simulator specifically includes:

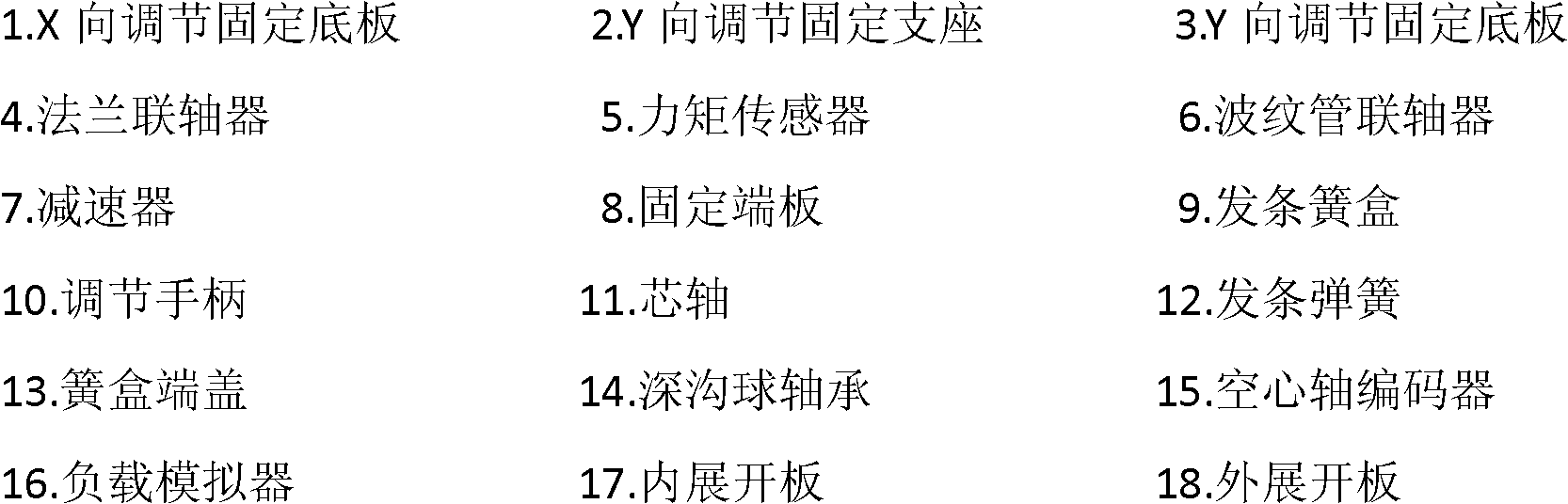

[0028] Two X-direction adjustment fixed base plates 1; one Y-direction adjustment fixed support 2; one Y-direction adjustment fixed base plate 3; one flange coupling 4; one torque sensor 5; one bellows coupling 6; one reducer 7; a fixed end plate 8; a clockwork spring box 9; two adjustment handles 10; a mandrel 11; a clockwork spring 12; a spring box end cover 13; a deep groove ball bearing 14; a hollow shaft code Device 15.

[0029] The specific connection between the components of the load simulation device is described as follows:

[0030] Two X-direction adjustable fixed base plates 1, one of which is fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com