Novel magnetosensitive temperature control device for electric heating containers

A technology of temperature control device and heating container, which is applied in the direction of thermal switch parts, etc., can solve the problems of poor corrosion resistance, harsh heat treatment conditions, poor temperature control accuracy, etc., and achieve the effect of improving temperature control sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

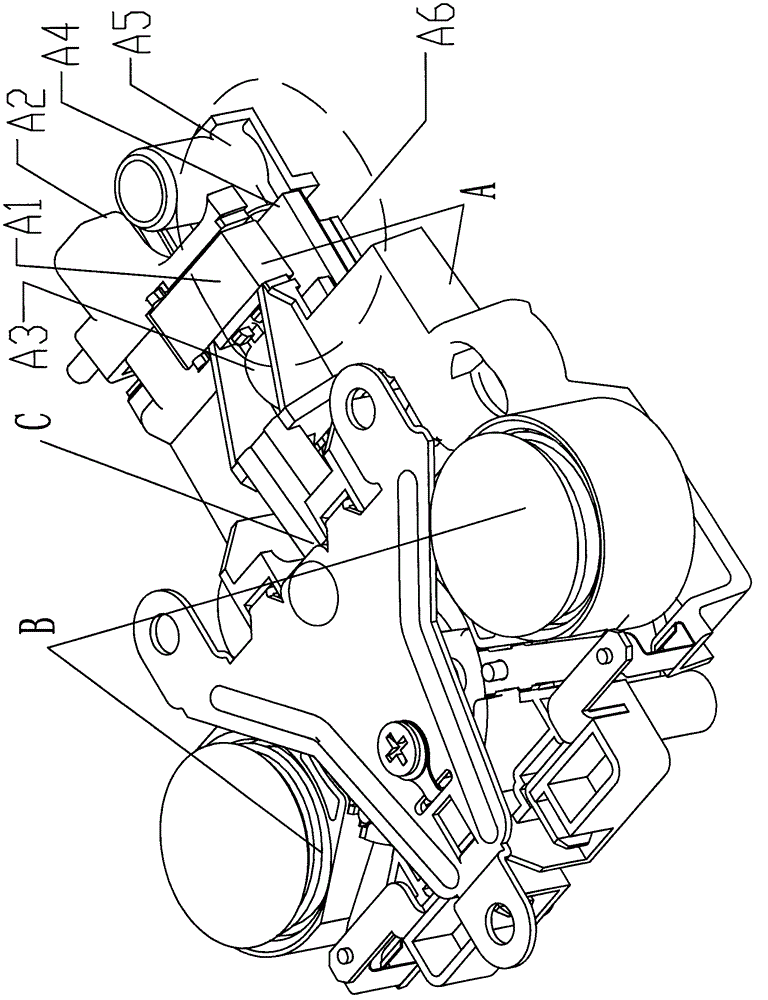

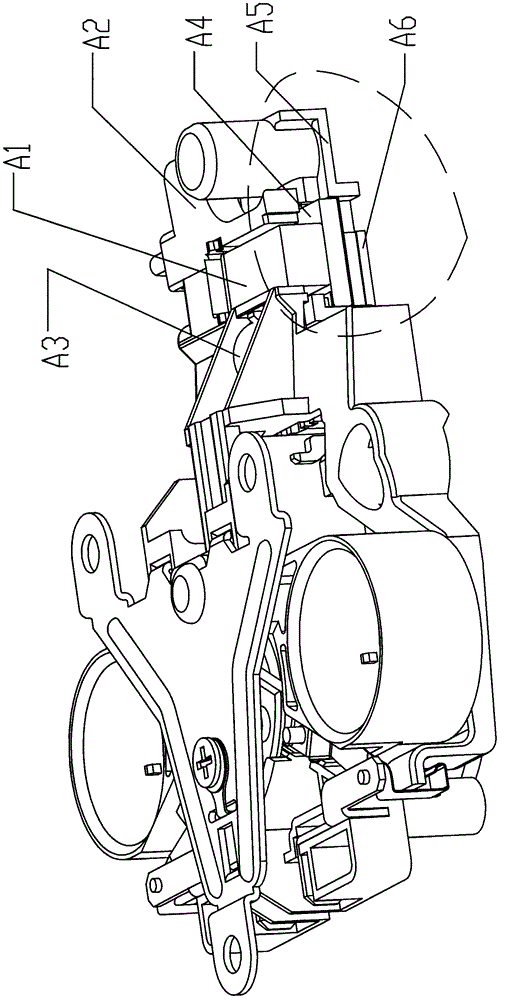

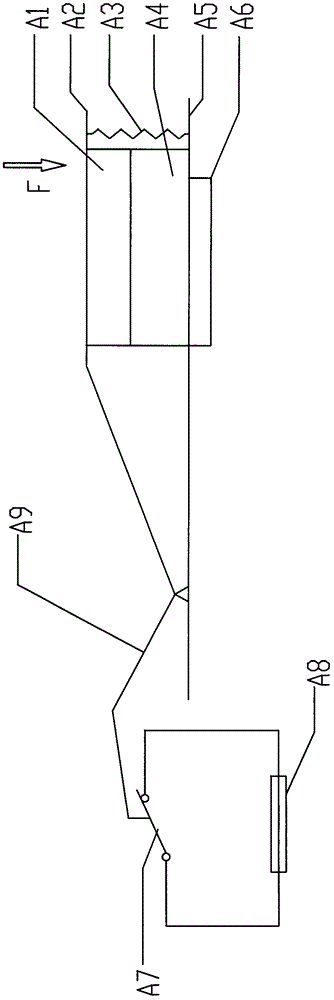

[0026] The present invention will be further described in detail with an embodiment below, but it should be noted that the protection scope of the present invention is not limited thereto. see Figure 1 to Figure 11 .

[0027] A magnetically sensitive temperature control device for an electric heating container, which includes a new magnetically sensitive steam brake A, a magnetically sensitive temperature controller braking device B, a lifting power-off function device D, and an electrical connector C. The novel magnetic-sensitive steam brake A includes a base A5 and a movable part A2 mounted on the base A5, on which a first soft magnet A4 and a second hard magnet A6 are fixed, and the second hard magnet A6 is placed on the first soft magnet. Below A4, the first hard magnet A1 is fixed on the movable part A2, one end of a reed A3 is fixed on the base A5 and the other end of the reed A3 is fixed on the movable part A2, the steam port of the base A5 and the heating container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com