Magnetically soft ferrite thermosensitive magnetic core and preparation method thereof

A soft magnetic ferrite and magnetic core technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic cores/yokes, transformers/inductor cores, etc., can solve the problem of poor temperature control sensitivity and electromagnetic characteristics of magnetic-sensitive thermal protection switches. Instability, low product qualification rate and other problems, achieve the effect of small temperature control range, reduced Curie temperature fluctuation, and high temperature control sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

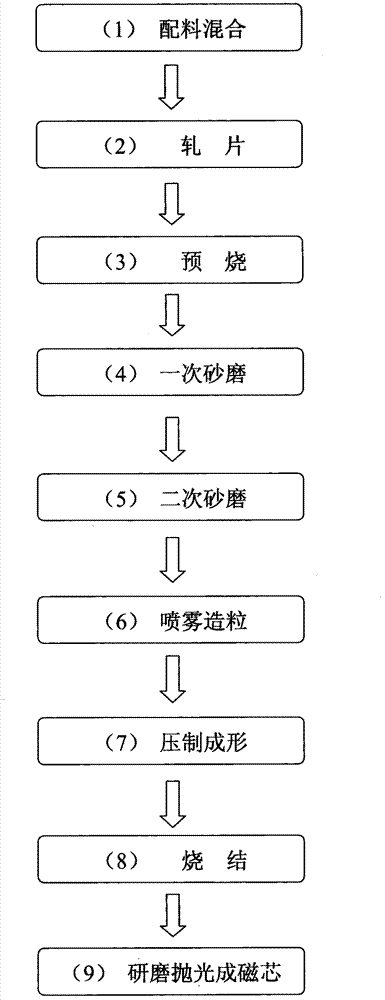

[0022] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] refer to figure 1 , a method for manufacturing a soft ferrite heat-sensitive magnetic core of the present invention, its concrete steps are as follows:

[0024] (1) Mixing ingredients: 15% to 20% of powder containing ZnO element, 5% to 8% of powder containing MgO element, 5% to 10% of powder containing CuO element, and the rest is Fe 2 o 3 And the unavoidable powder ratio Weigh the powder, add 5% to 6% of the weight of the powder PVA glue, the glue concentration is 9% to 10%, add it to the mixer and mix it into a composite material;

[0025] (2) Sheet rolling: add the above combined materials into the sheet rolling machine for rolling, and roll the sheets according to the thickness of 2.5 ~ 3mm, and roll them into sheets;

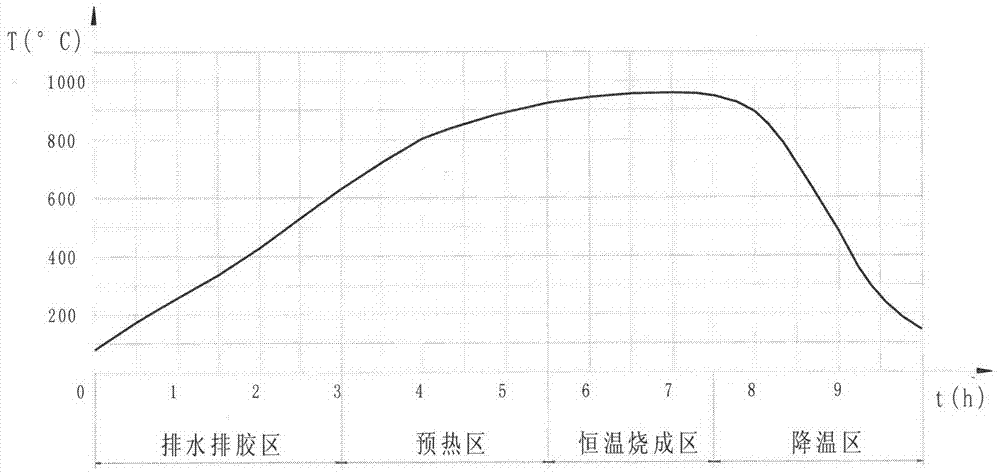

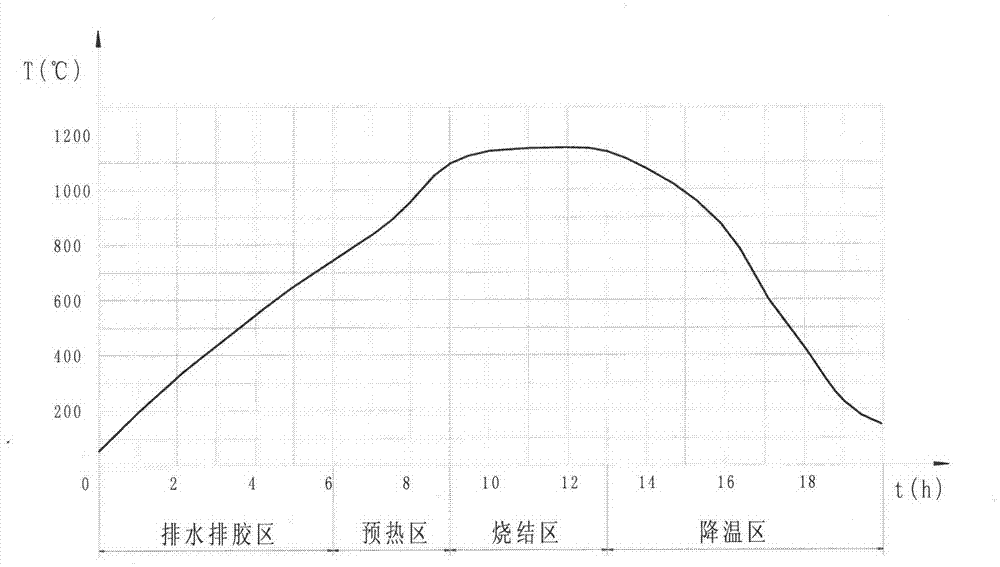

[0026] (3) Pre-burning: Put the above-mentioned combined materials into the pre-burning furnace, heat to 500°C-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com