Electric-frying oven temperature control circuit

A temperature control and temperature controller technology, applied in the electronic field, can solve the problems of the difference between the frying time and the theoretical time, the inability to set the food frying time, and the lack of consideration of the initial temperature of the food, etc., to achieve high sensitivity, convenient operation, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

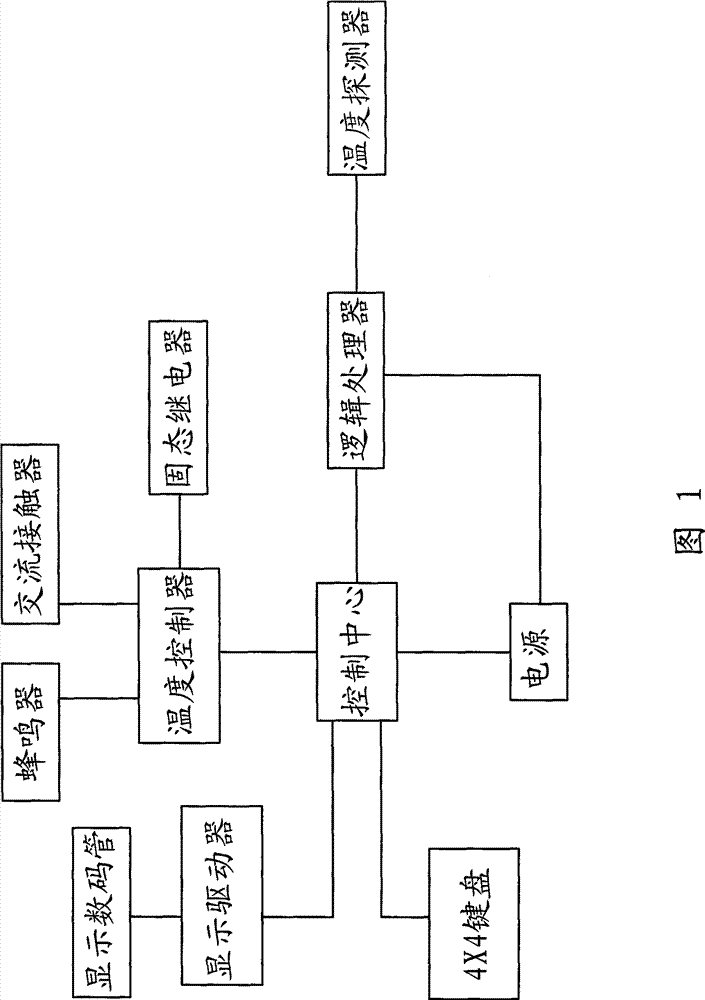

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0023] Such as figure 1 As shown, the temperature control circuit of the electric fryer includes a control center and a power supply for supplying power to the control circuit. The control center is also connected with a temperature controller for controlling the oil temperature of the electric fryer and a logic processor for analyzing and processing the oil temperature. The logic processor is connected with a temperature detector, and the temperature detector detects the oil temperature in the fryer, and transmits the detected temperature information to the logic processor.

[0024] The staff selects the working mode and sets various working values through the operation keyboard connected to the control center, and disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com