Dental material with color indicator and methods of using same

A dental and color technology, applied in dentistry, dental prosthesis, dental preparations, etc., can solve problems such as it is difficult to distinguish the position of excess material, and it is difficult to see where the adhesive is placed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

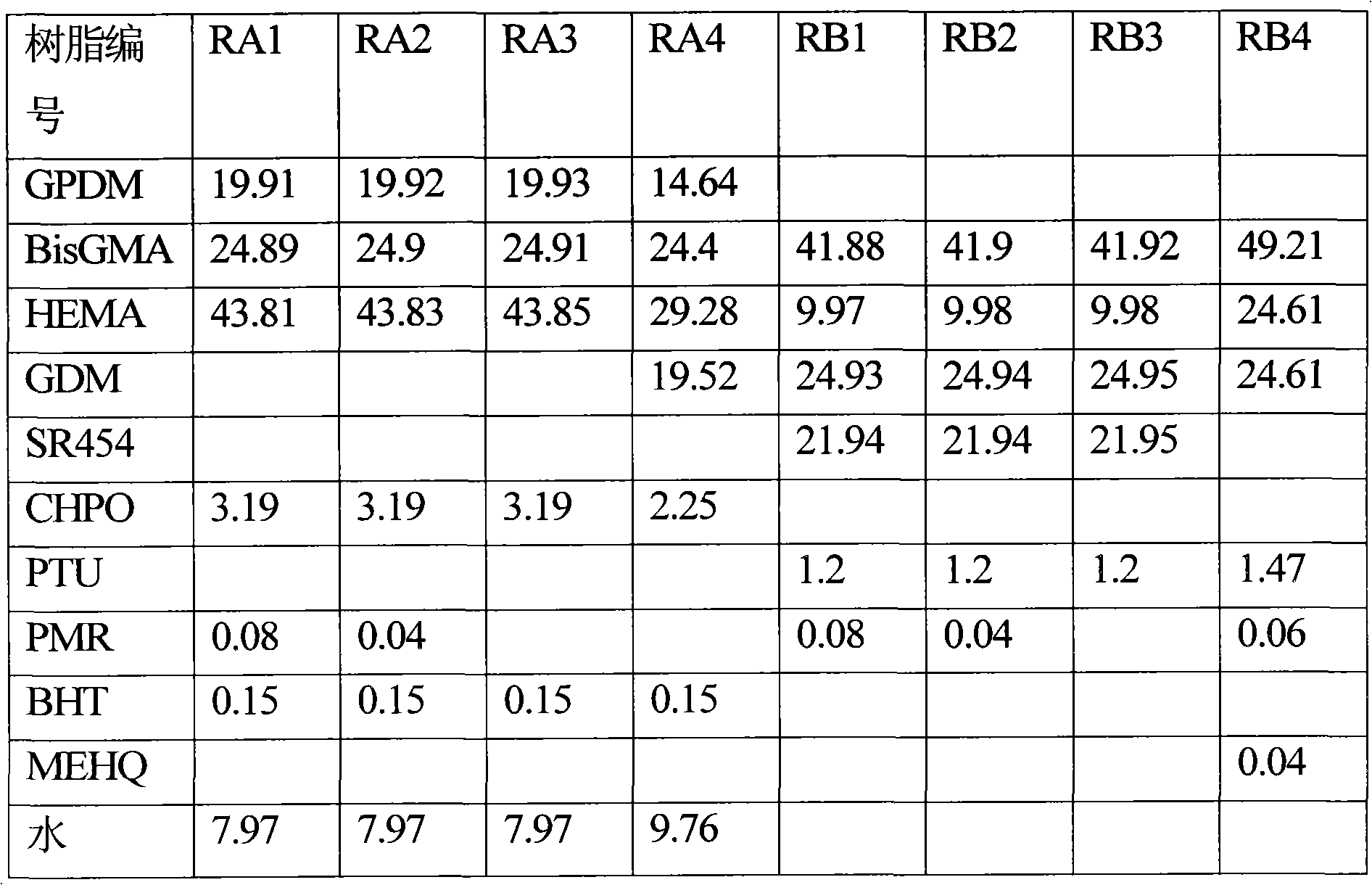

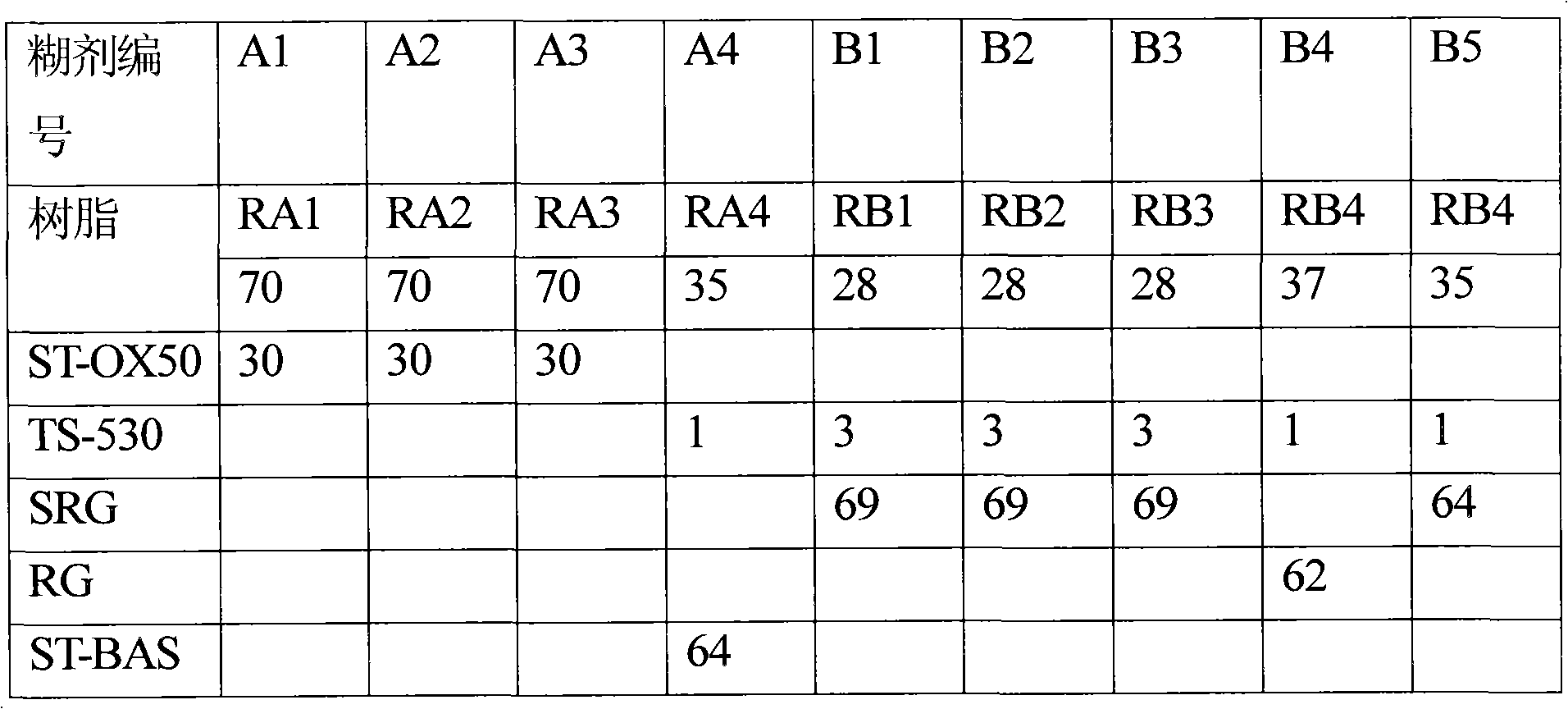

Method used

Image

Examples

Embodiment 1

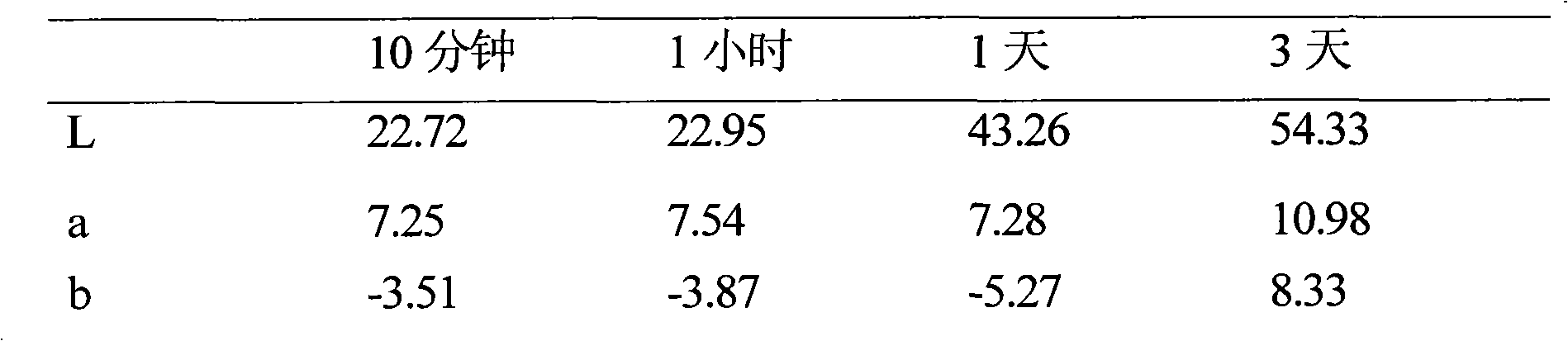

[0047] Paste A1 was mixed with paste B3 in a ratio of 1:1. Mixing was accomplished by centrifugation at approximately 3000 RPM (revolutions per minute) for 15 seconds. The mixed paste has a dark purple color. This paste was placed in a metal mold having a thickness of 1 mm and a diameter of 20 mm. The mixture cured to a hard disk within 10 minutes. The color of the paste at this point was dark purple. After 1 day in water at 37°C, the purple color became significantly lighter, and after 3 days in water at 37°C, the purple color almost disappeared (very light purple). Color was measured as quickly as possible (10 minutes, 1 hour, 1 day and 3 days) using the L, a and b systems and the results are listed in Table 3.

[0048] Table 3. Color measurements of mixtures of A1 and B3 (1:1 ratio)

[0049]

Embodiment 2

[0051] Paste A2 was mixed with paste B3 in a ratio of 1:1. Mixing was accomplished by centrifugation at approximately 3000 RPM (revolutions per minute) for 15 seconds. The mixed paste has a dark purple color. This paste was placed in a metal mold having a thickness of 1 mm and a diameter of 20 mm. The mixture cured to a hard disk within 10 minutes. At this point, the paste was dark purple in color. After 1 day in water at 37°C, the purple color became significantly lighter, and after 3 days in water at 37°C, the purple color almost disappeared. Color was measured as quickly as possible (10 minutes, 1 hour, 1 day and 3 days) using the L, a and b systems and the results are listed in Table 4.

[0052] Table 4. Color measurements of mixtures of A2 and B3 (1:1 ratio)

[0053]

Embodiment 3

[0055] Paste A3 was mixed with paste B1 in a ratio of 1:1. Mixing was accomplished by centrifugation at approximately 3000 RPM (revolutions per minute) for 15 seconds. The mixed paste has a dark purple color. This paste was placed in a metal mold having a thickness of 1 mm and a diameter of 20 mm. The mixture cured to a hard disk within ten minutes. At this point, the paste was dark purple in color. After 1 day in water at 37°C, the purple color became significantly lighter, and after 3 days in water at 37°C, the purple color almost disappeared (very light purple). Color was measured as quickly as possible (10 minutes, 1 hour, 1 day and 3 days) using the L, a and b systems and the results are listed in Table 5.

[0056] Table 5. Color measurements of mixtures of A3 and B1 (1:1 ratio)

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com