Longitudinal beam oil cylinder support for rotary drilling rig

A technology of rotary drilling rig and oil cylinder support, which is applied in the directions of motor vehicles, earthwork drilling, drilling equipment, etc., can solve the problems of loosening, failure and structural failure of threaded connection structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

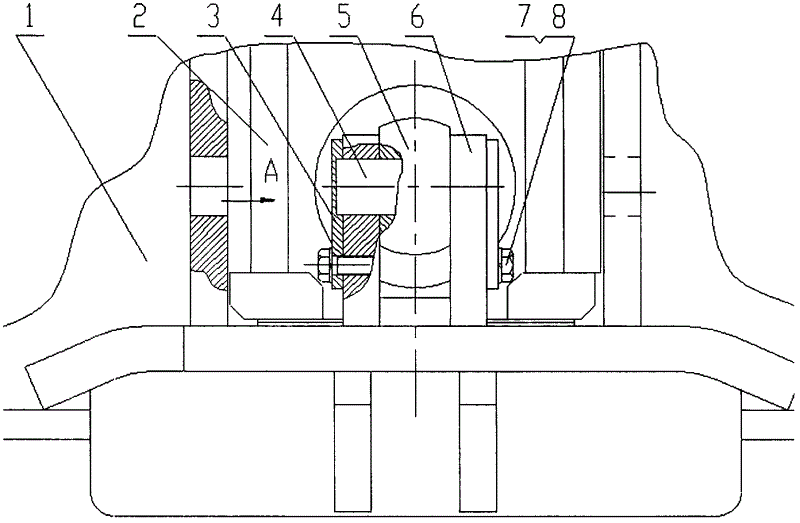

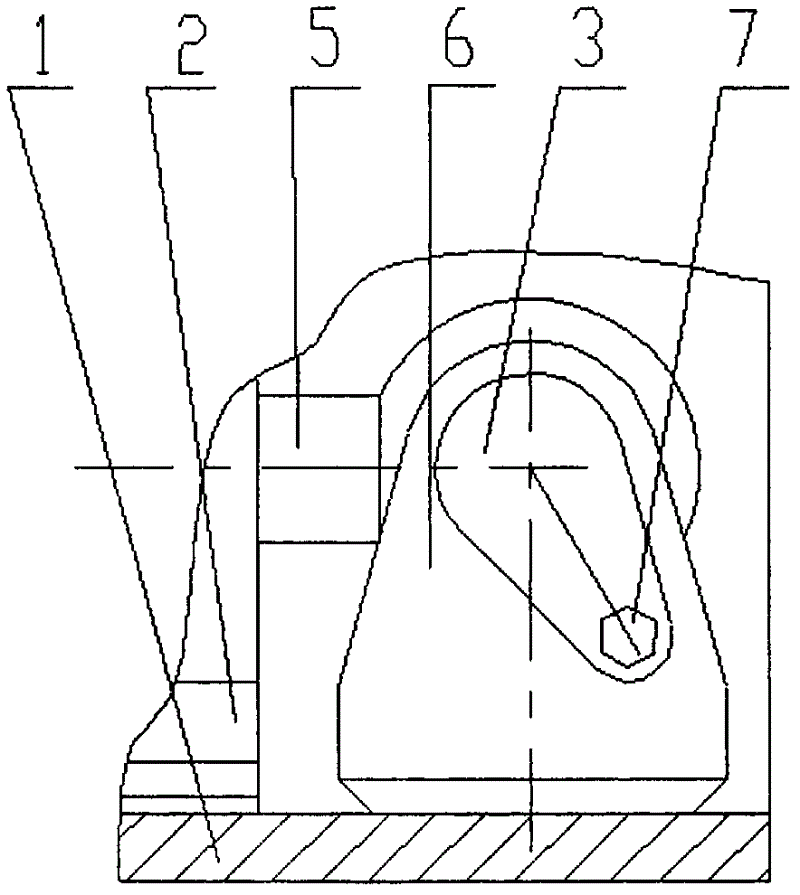

[0012] Weld the support (6) in the middle of the rectangular box bottom plate of the longitudinal beam (1) according to the requirements, and hinge one end of the oil cylinder (5) to the inside of the cantilever beam of the H-shaped vehicle frame (2); The box body is enclosed within the cantilever beam on one side of the H-shaped vehicle frame (2), and the piston rod of the oil cylinder (5) is properly extended so that the lug of the piston rod is placed in the middle of the support (6), and from the longitudinal beam (1 ) through the round hole on the side of the rectangular box body, insert the pin shaft (4) into the hole of the piston rod lug; and ensure that the pin shaft is correctly placed in the hole of the bracket (6), then install the fixed ear plate (3), and at the same time Install the bolts (7) and washers (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com