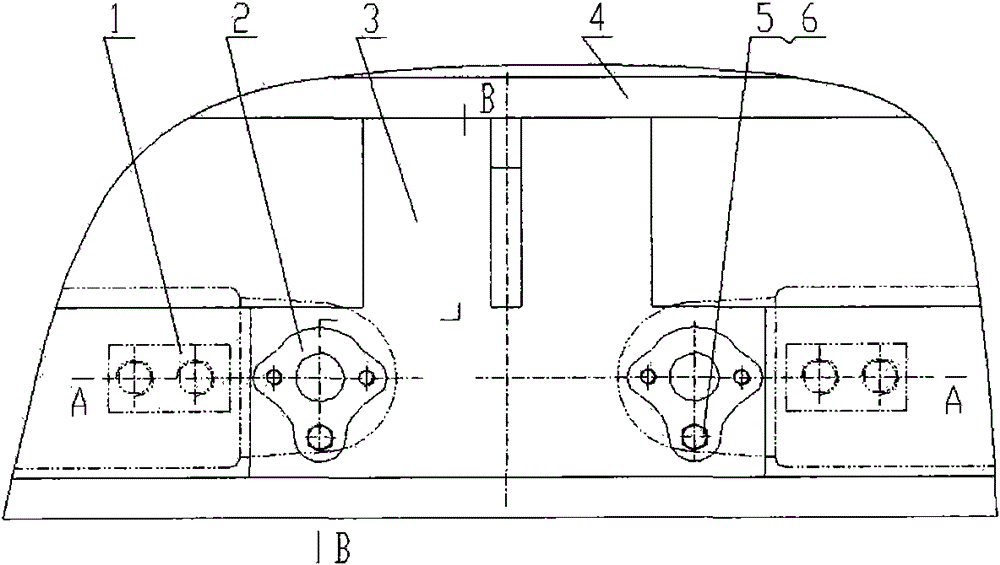

Oil cylinder support structure with H-shaped frame

A technology of oil cylinder support and frame, applied in drilling equipment, drilling equipment and methods, impact drilling and other directions, can solve problems such as structural failure, loose threaded connection structure, structural thread damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

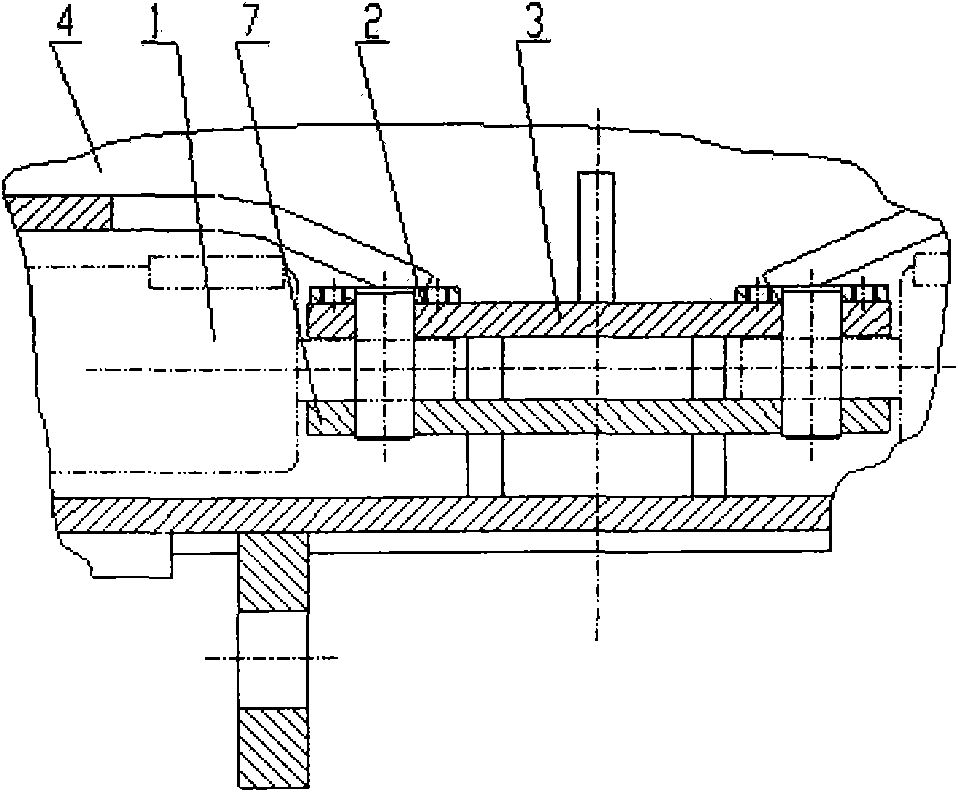

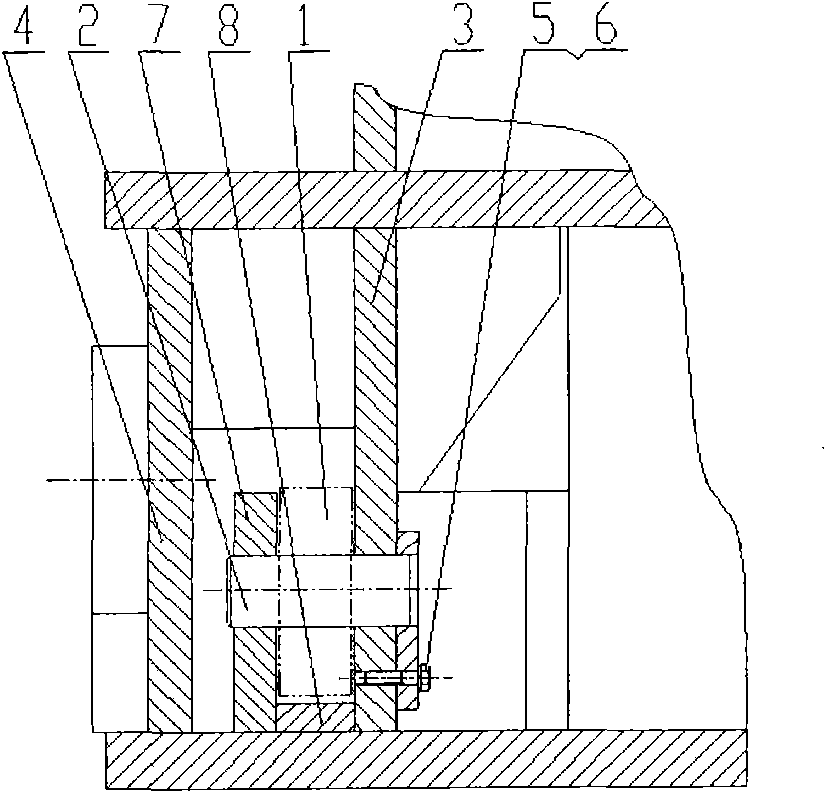

[0014] According to the requirements, the main vertical plate (3), auxiliary plate (7) and bottom plate (8) are welded into a part, and after proper mechanical processing, the part is put into the middle position of the cantilever structure inside the H-shaped vehicle frame (4) On the lower cover, implement the welding seam connection between this component and the relevant parts of the H-shaped vehicle frame (4). Put the lug at one end of the cylinder of the oil cylinder (1) in the inner crotch formed by the main vertical plate (3) and the auxiliary plate (7), and ensure the coaxiality of the three round holes, and then install the pin shaft (2) , Washer (5) and bolt (6).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com