Steam turbine drainage device

A steam turbine and water-repellent technology, which is applied in the connection with fluid cut-off device, mechanical equipment, flange connection, etc., can solve the problems of complex connection structure between the steam turbine drain and the water pipe, unfavorable rapid drainage, low drainage efficiency, etc., and achieve improvement The efficiency of assembly production, the improvement of practical convenience, and the effect of rapid assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

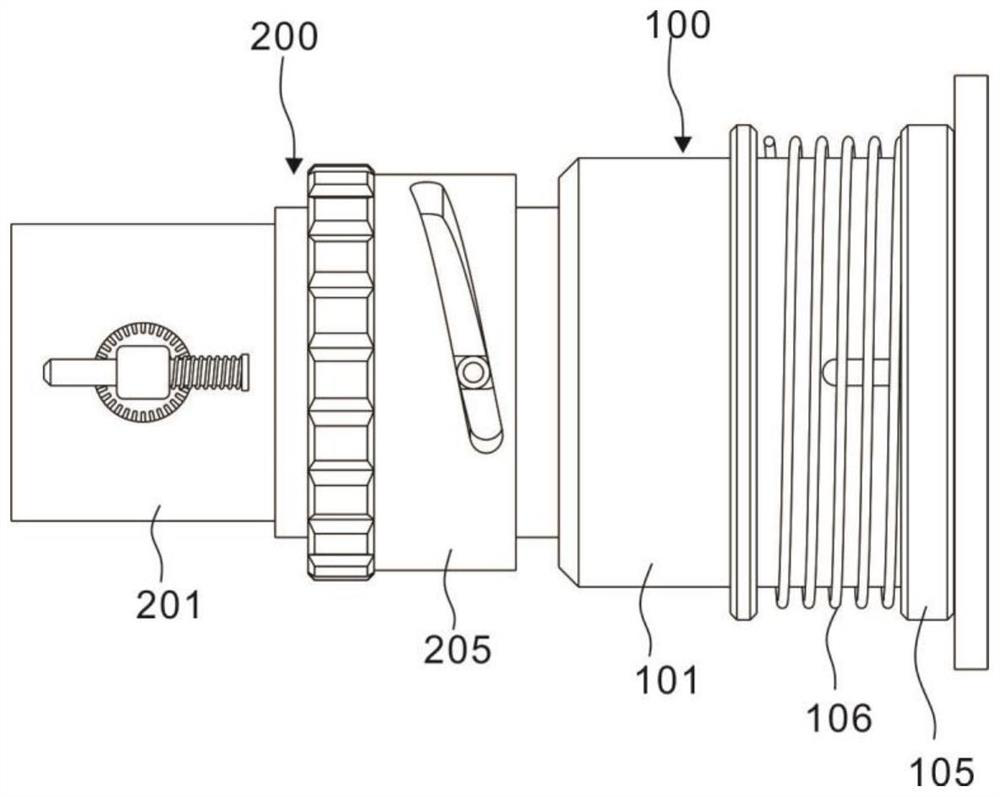

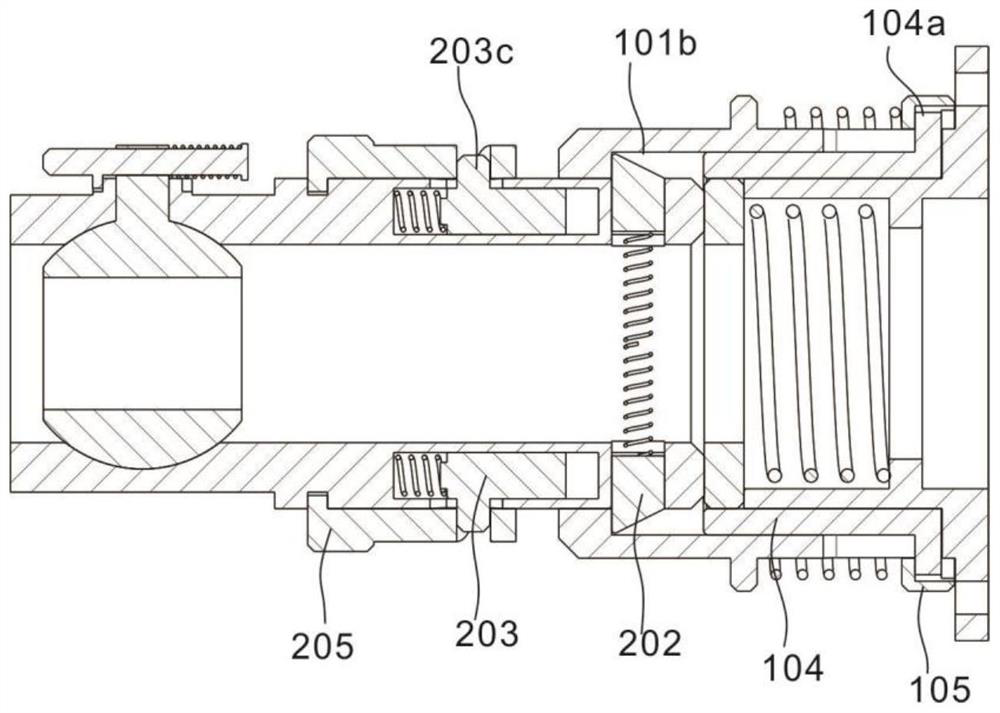

[0034] refer to Figure 1~2 , 5, 6, this embodiment provides a steam turbine drainage device, including a fixed joint 100 and a movable joint 200, wherein the fixed joint 100 is fixedly installed at the drain of the steam turbine, and the movable joint 200 is connected to the movable joint 200 before being connected to the drain pipeline.

[0035]Wherein, the fixed joint 100 includes a connecting seat 101, the connecting seat 101 is a rotating body, the connecting seat 101 is provided with a first through hole 101a through, the connecting seat 101 is provided with a connecting flange 101d, and the connecting flange 101d is fixedly connected to the drain port of the steam turbine , the first through hole 101a communicates with the steam turbine drain, and the first through hole 101a is provided with an annular groove groove 101b; the inner diameter of the annular groove groove 101b is larger than the inner diameter of the first through hole 101a, and the connecting head 201 is ...

Embodiment 2

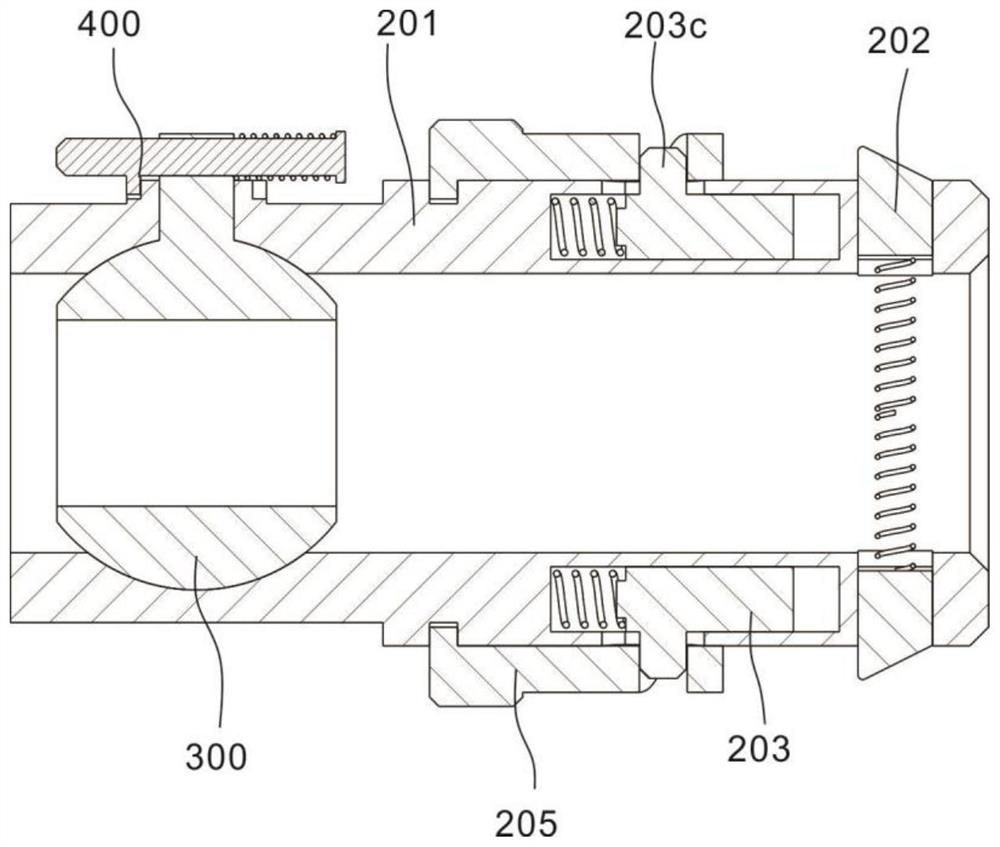

[0047] refer to Figure 1-8 , is the second embodiment of the present invention, this embodiment is based on the previous embodiment, and differs from the previous embodiment in that:

[0048] Wherein, the connection seat 101 is provided with a first through hole 101a penetrating, and the first through hole 101a is used to connect with the connector 201; the first through hole 101a is provided with a ring groove groove 101b, and the ring groove groove 101b The inner diameter is greater than the inner diameter of the first through hole 101a; the outer diameter of the connector 201 is consistent with the inner diameter of the first through hole 101a, and the connector 201 is provided with a second through hole 201a that passes through. When the connector 201 is connected to the connection seat 101, the second The second through hole 201a communicates with the first through hole 101a to deliver gas; the side of the second through hole 201a is provided with a chute 201b extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com