Turbulence generator for medium-consistency paper pulp pump

A turbulence generator and pulp pump technology, applied in the field of turbulence generators, can solve the problems of lack of self-fluidity and high gas hold-up of medium-consistency pulp, and achieve the effect of improving gas conveying capacity, reducing hydraulic loss and smooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The implementation of the present invention is described in detail below, and the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following examples .

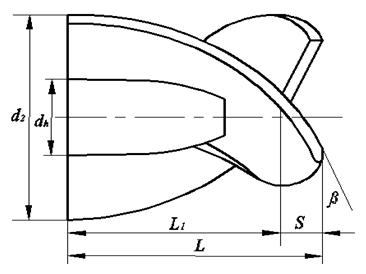

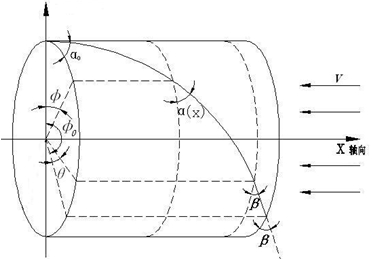

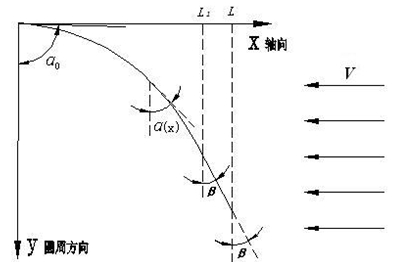

[0046] like figure 1 As shown, the turbulence generator 1 of the present embodiment is installed on the front end of the pump impeller 2, and is installed on the same shaft as the pump impeller; figure 2 As shown, the turbulence generator consists of a hub 3 and a helical blade 4 fixed on the hub. The spiral blade 4 is composed of an inlet surface 5 , a working surface 6 , a back surface 7 , an outlet surface 8 and an outer edge surface 9 . Wherein the working surface 6 is a three-dimensional space curved surface, which is composed of an inlet edge 10, a blade outer edge profile (blade profile) 11 and an out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com