Self-adapting optical system based on differential sensor

An adaptive optics and sensor technology, applied in the field of optics, can solve the problems of high energy utilization, complex coupling technology, affecting sensor accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, with reference to figure 1 , an adaptive optics system based on a differential sensor, which is composed of a differential sensor, a main control computer and a wavefront corrector to correct aberrations Reflected or transmitted through the wavefront corrector, with the wavefront corrector compensation amount superposition to obtain the corrected residual aberration , the residual aberration After entering the differential sensor, the CCD camera in the differential sensor records in real time the +1 order and -1 order diffraction images of the residual wavefront after compensation by the wavefront corrector, and then obtains the signal difference through the image acquisition card and differential operation ;The main control computer according to the input signal difference , generate the driving signal U of the wavefront corrector according to the real-time control algorithm;

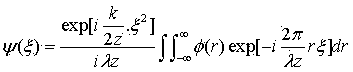

[0046] The drive signal U is calculated by the following formula: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com