Rectifier bridge arm

A rectifier bridge, a pair of technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., to achieve the effect of improving efficiency, eliminating branch impedance differences, and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained and illustrated below in conjunction with the embodiments and accompanying drawings.

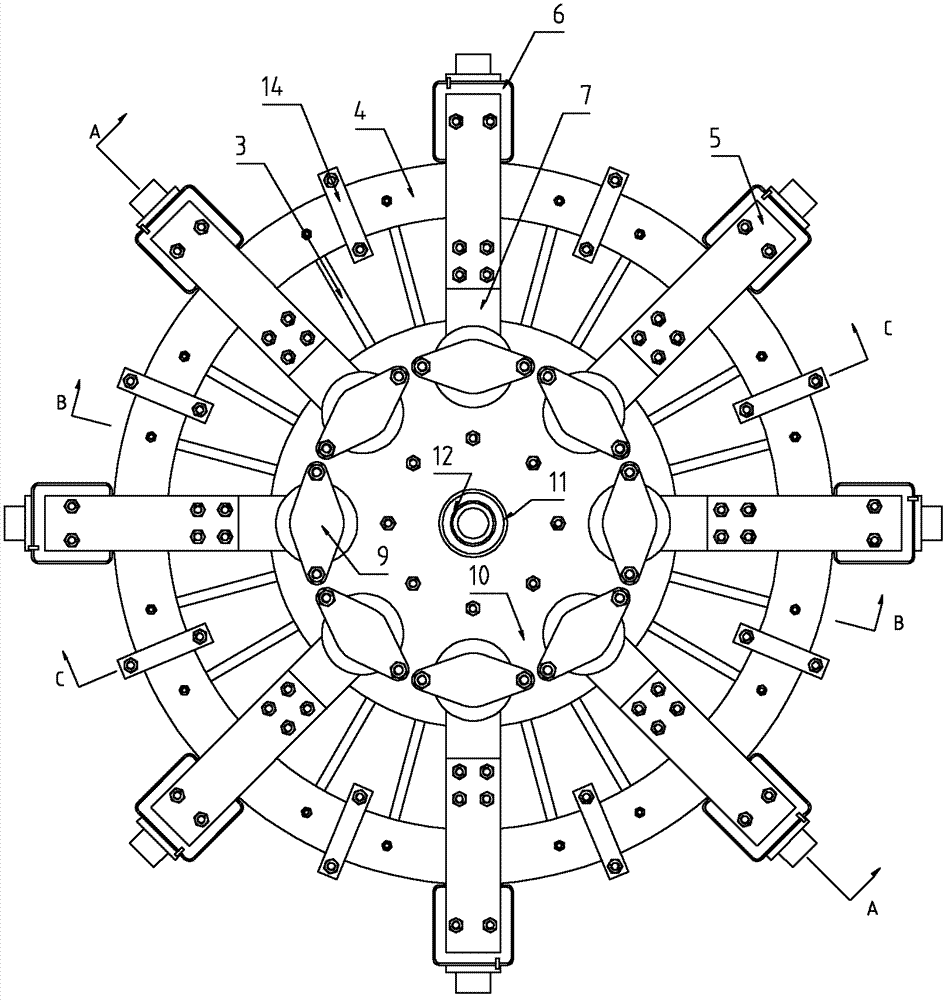

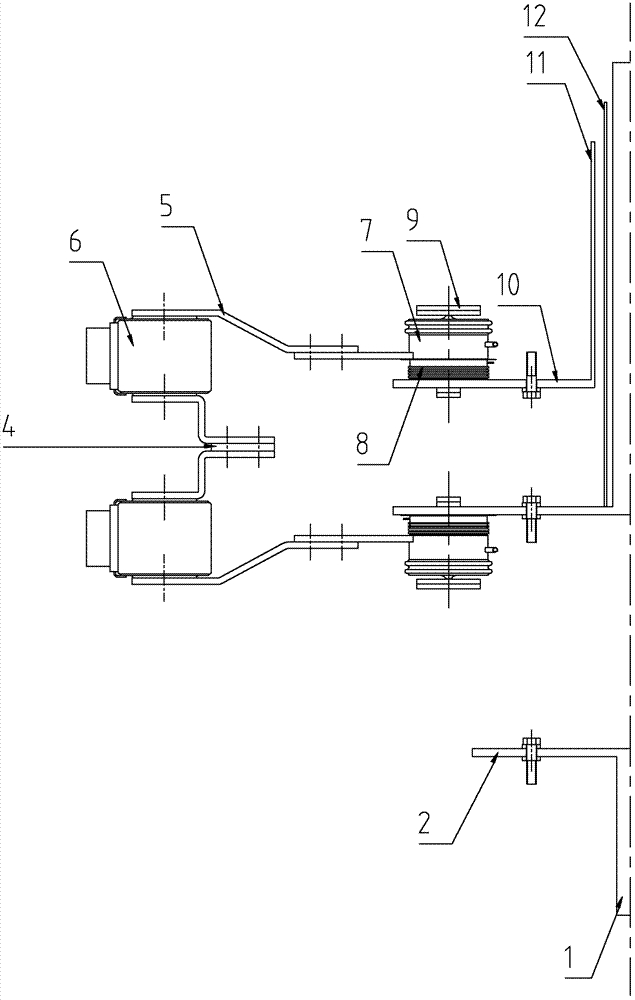

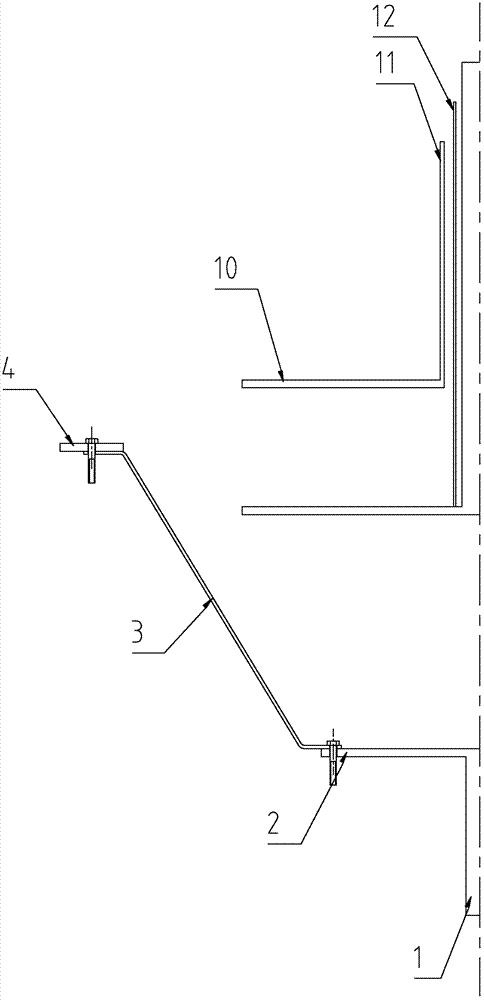

[0023] Such as figure 1 and 2 As shown, the rectifier bridge arm of the present invention includes an AC incoming line column 1, a pair of AC pole plates 2, a plurality of AC connecting bars 3, an AC bus bar 4, a plurality of DC connecting bars 5, a plurality of fast fuses 6, and a plurality of A heat sink 7, a plurality of semiconductor switching devices 8, a plurality of crimping fixtures 9, a pair of DC plates 10 and a pair of DC outlet posts 11.

[0024] Such as figure 1 As shown, the AC busbar 4 is ring-shaped, the DC pole plate 10 and the AC pole plate 2 are circular, the AC busbar 4 is arranged outside the DC pole plate 10, the DC outlet column 11 is arranged in the center of the DC pole plate 10, and the crimping fixture 9 are evenly distributed along the circumferential direction, the fast fuses 6 are evenly distributed along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com