Ejection-type self-destructive syringe

A technology for syringes and injection barrels, which is applied in the direction of syringes, hypodermic injection devices, infusion sets, etc. It can solve the problems of complex structural design, high production cost, troublesome use, etc., and achieve the effect of simple operation, low production cost and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

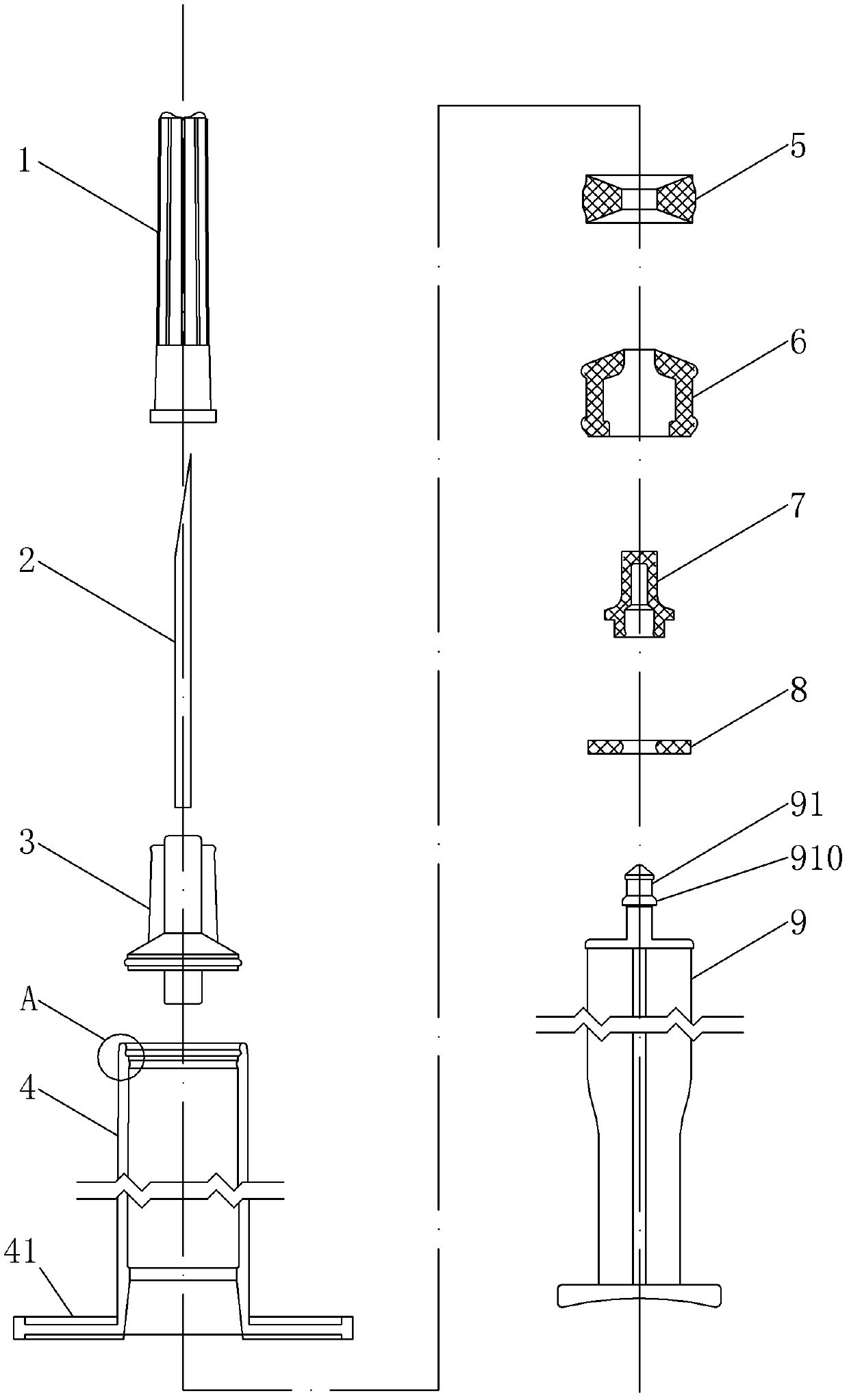

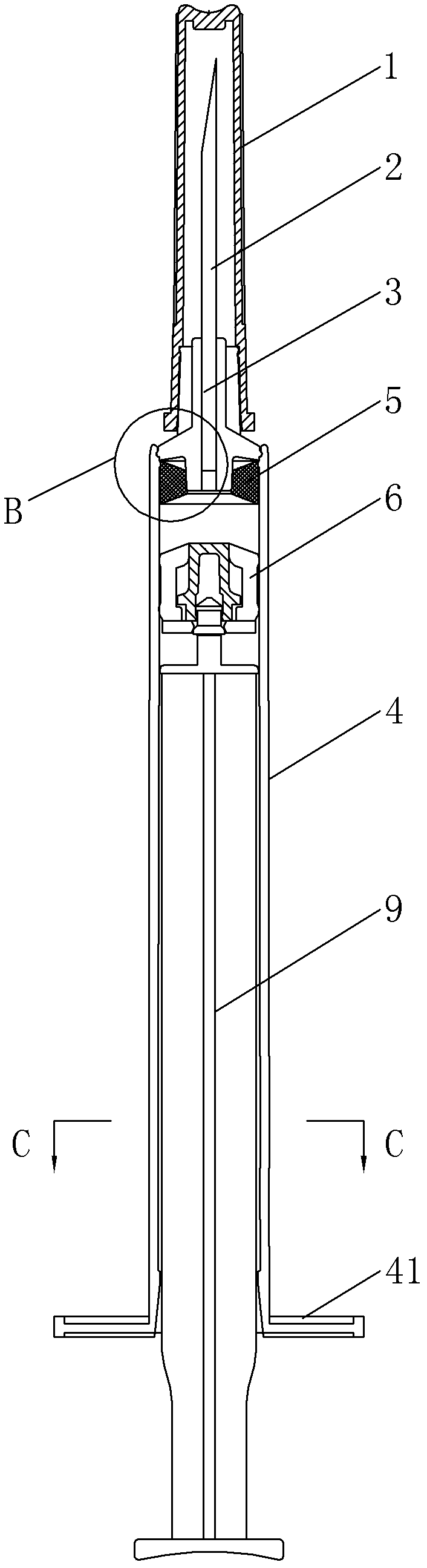

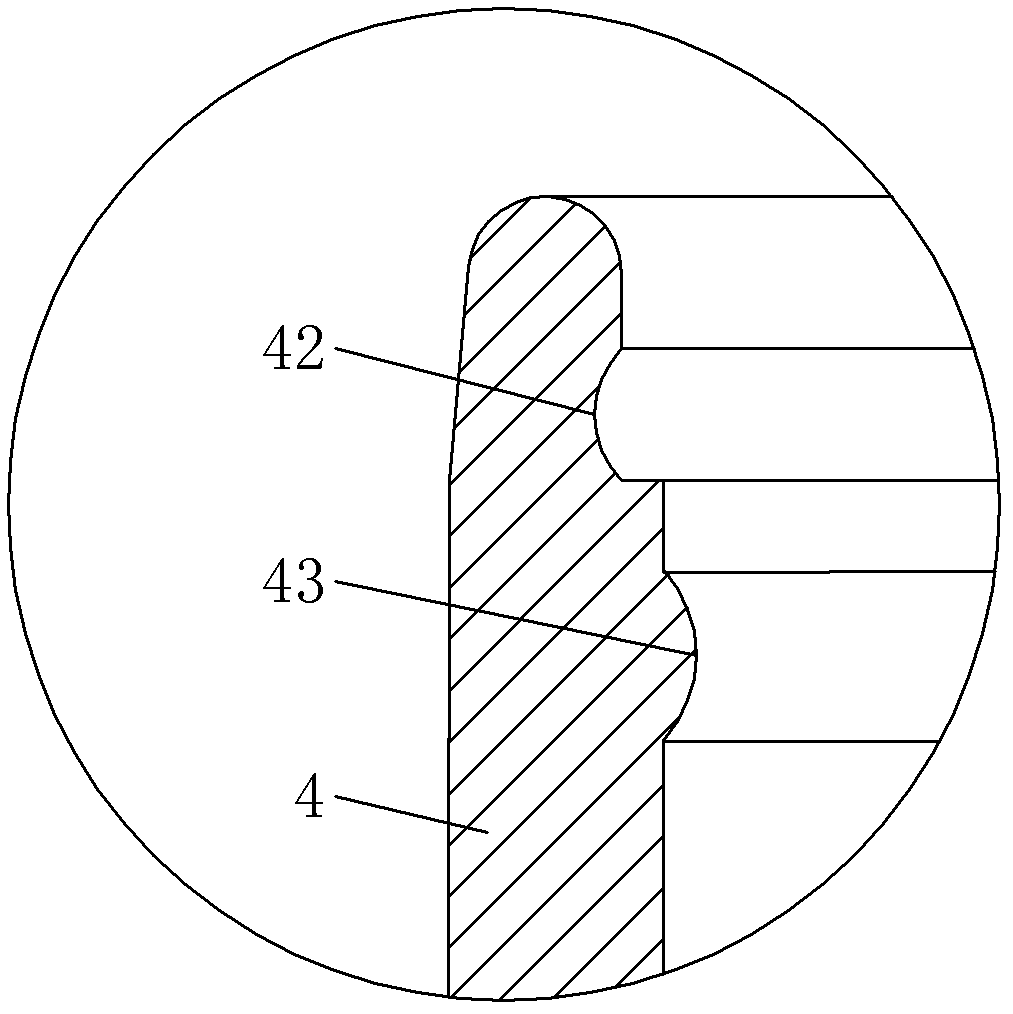

[0020] Example 1, such as Figure 1-6 As shown, a ejection self-destructing syringe includes a syringe 4, an injection rod 9, a needle seat 3 and a needle 2 fixed on the needle seat 3, and the needle seat 3 is provided with a channel connecting the needle 2 and the syringe 4. The liquid hole, the upper end of the injection rod 9 is provided with a piston 6, and the inner wall of the end of the injection cylinder 4 connected to the needle seat 3 is formed with an annular groove 42, and the lower end of the needle seat 3 is formed with the groove 42. The matching rib 31, the needle base 3 on the lower side of the rib 31 is covered with a sealing ring 5 that is in close contact with the inner wall of the injection barrel 4, and the sealing ring 5 ensures that the medicinal liquid will not pass through the needle base 3 and the injection barrel during injection 4's fitting clearance bleeds out to the outside.

[0021] The middle part of the upper end of the above-mentioned inject...

Embodiment 2

[0025] Example 2, such as Figure 7 with Figure 8 As shown, this embodiment is basically the same as Embodiment 1, the difference is that: the upper end of the syringe 4 is radially retracted to form a needle seat installation part 46, and a groove 42 is formed on the inner wall of the upper end of the needle seat installation part 46, The needle base 3 is formed with a convex rib 31 that snaps into the groove 42, and the lower part of the needle base 3 is provided with a sealing ring 5, and the limiting convex rings on the upper and lower sides of the sealing ring 5 (43 is the upper limit convex ring, 45 is the lower limit convex ring) are all molded on the inner wall of the needle holder mounting part 46 of the injection cylinder, the needle holder 3 of this embodiment can be pushed out of the injection cylinder 4 by the injection rod 9, while the sealing ring 5 cannot be pushed out ( The shape of the upper limit protruding ring 43 determines whether the sealing ring 5 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com