Novel color sorter

A color sorter, a new type of technology, applied in the field of color sorters, can solve the problems of affecting the image collection effect, inconsistent material sliding speed, material tumbling, etc., and achieve high color selection accuracy and good material image collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

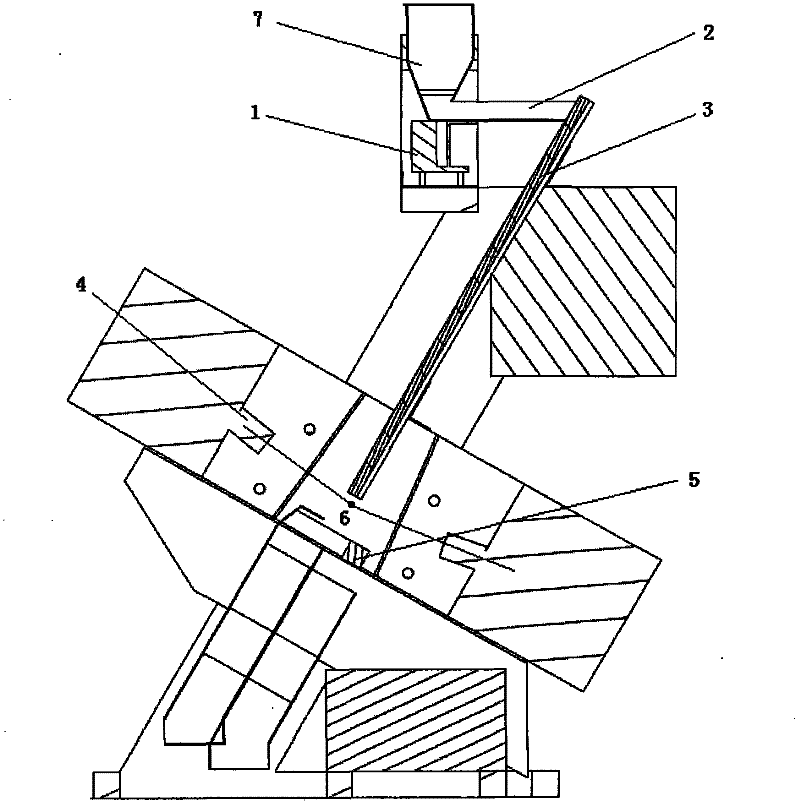

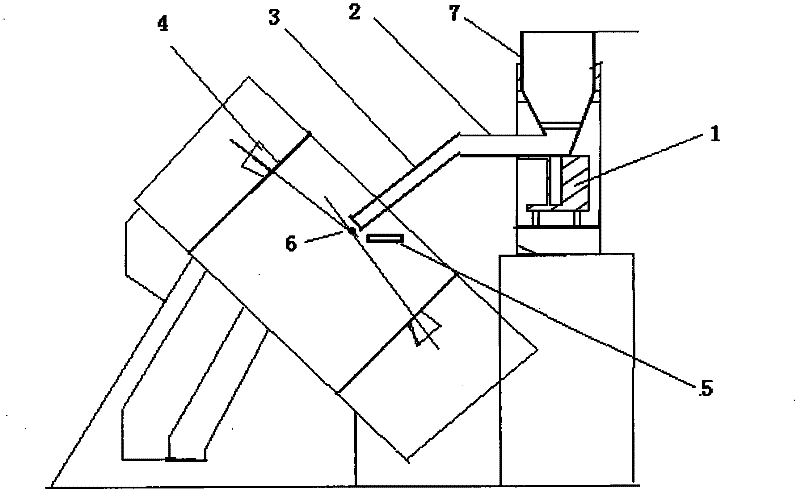

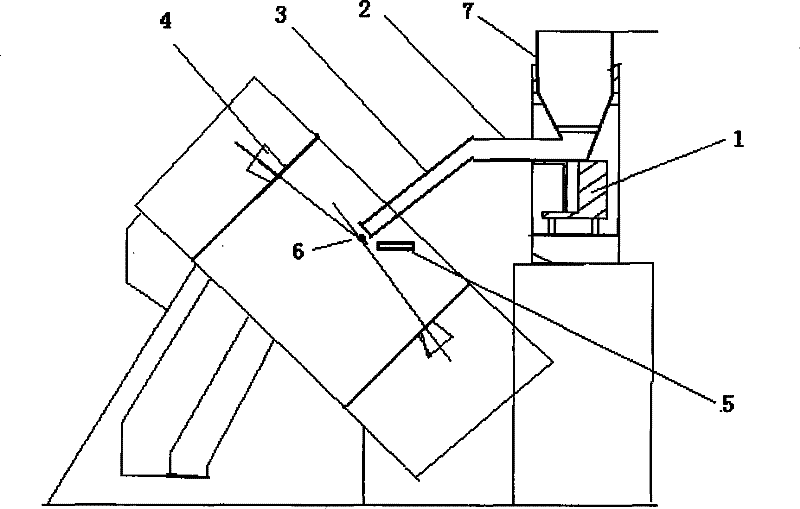

[0009] A novel color sorter, characterized in that the blanking system includes a vibrator (1), a hopper (2), a slideway (3), a CCD (4), and a spray valve (5). The material is vibrated by the vibrator and flattened onto the hopper, and slides down the slideway. After the material picture is collected by the CCD and identified by the color sorter system, the unqualified material is separated by the spray valve (5). Such as figure 2 shown.

[0010] Such as figure 2 As shown, the vibrator (1) is connected to the vibrating hopper (2), the outlet of the vibrating hopper (2) is connected to the slideway (3), and the collection intersection point 6 of the CCD (4) is located at the material passing through the slideway ( 3) For the outlet, the spray valve (5) is located directly below the collection intersection point 6 of the CCD (4). The horizontal line of the nozzle of the spray valve (5) is located below the collection point 6 of the CCD (4).

[0011] Such as figure 2 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com