Turn-off control device for electric spinning direct-writing jet printing

A technology of shut-off control and electrospinning direct writing, applied in printing devices, printing, etc., can solve the problems of no literature reports, long shut-off time, poor control effect, etc., to achieve accurate and fast shut-off, fast and accurate The effect of shutting down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

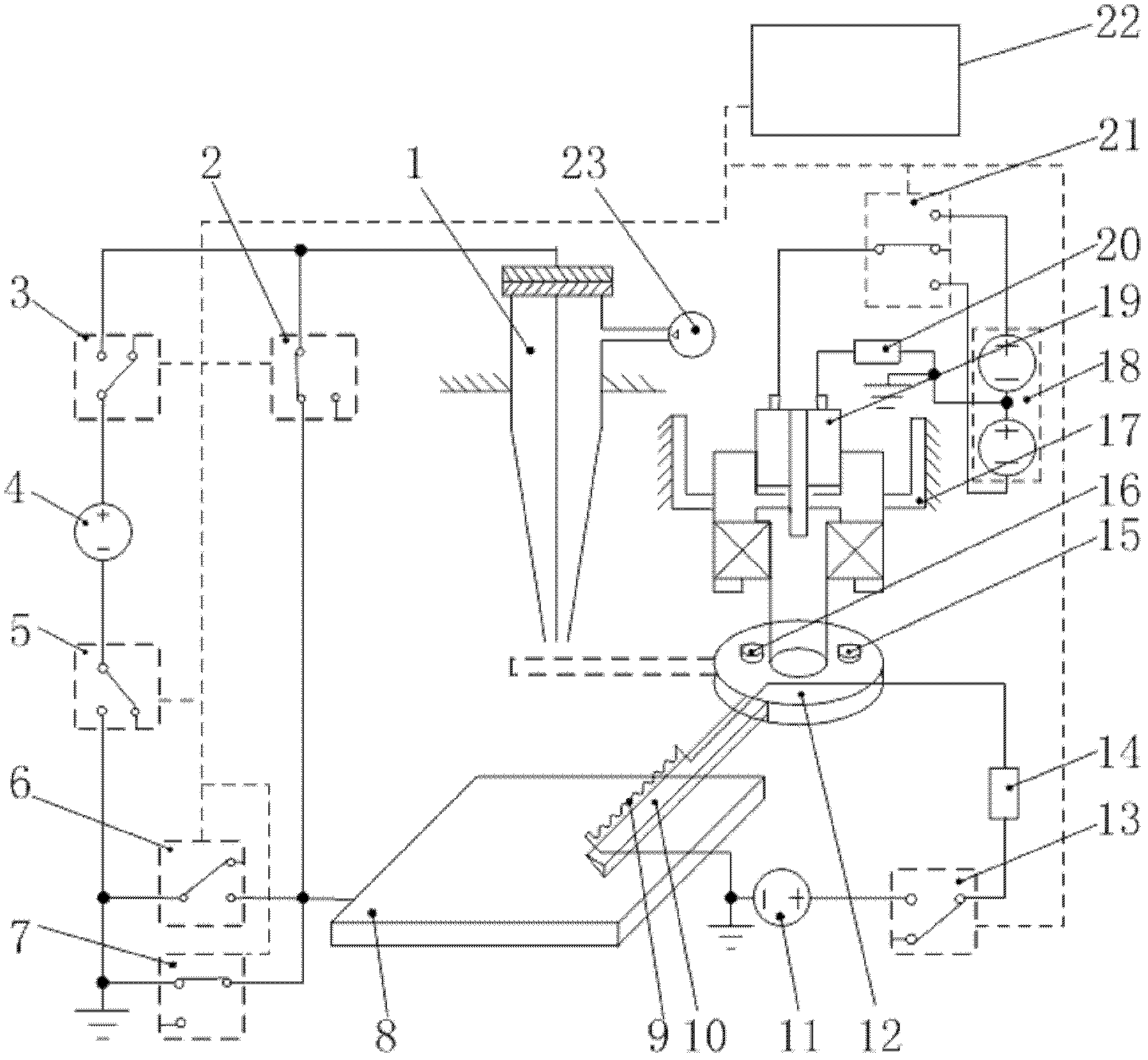

[0015] see figure 1 , the embodiment of the present invention is provided with nozzle 1, conductive relay 2, power supply high-voltage relay 3, DC high-voltage power supply 4, grounding high-voltage relay 5, grounding relay 6, delay relay 7, collection platform 8, heating wire 9, mechanical shut-off valve Sheet 10, heating DC power supply 11, mechanical shutoff valve turntable 12, temperature control relay 13, current limiting resistor 14, mechanical shutoff valve start limit 15, mechanical shutoff valve shutoff limit 16, bracket 17, three terminals DC power supply group 18, motor 19, protection resistor 20, electronically controlled single-pole three-throw switch 21 and controller 22.

[0016]The nozzle 1 is externally connected to the liquid supply device through the liquid supply pipeline, the nozzle 1 is connected to the common end of the conductive relay 2 and the normally open end of the power supply high voltage relay 3; the common end of the power supply high voltage r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com