Quick arc-shaped raised-edge drill rod dismounting device and method

A dismantling device and arc-shaped technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of long disassembly process, high labor intensity of workers, frequent safety accidents, etc., to shorten disassembly time and simple structure , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

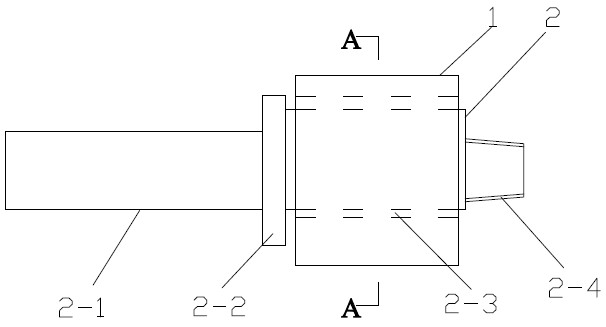

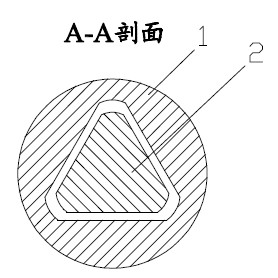

[0021] Such as figure 1 and figure 2 As shown in the figure, a quick release device for a circular-arc-shaped ribbed drill pipe includes a triangular sleeve 1 and a triangular shaft 2. The triangular sleeve 1 can slide axially on the triangular shaft 2, but cannot move relative to the triangular shaft 2. Circumferential rotation. The triangular shaft 2 is divided into four sections: cylinder section 2-1, limit plate 2-2, prism section 2-3, and external thread section 2-4, each of which is connected by welding.

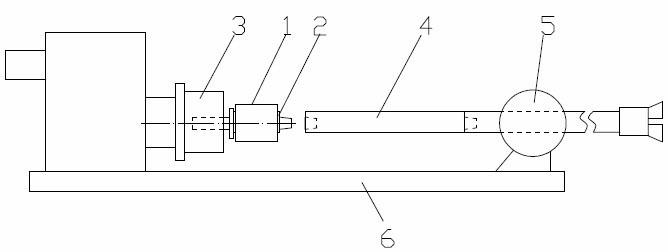

[0022] Such as image 3 , Figure 4 As shown, the cylindrical section 2-1 of the triangular shaft 2 is connected with the drill chuck 3, and rotates in the circumferential direction or moves axially together with the drill chuck 3, and the limit plate 2-2 cooperates with the end face of the drill chuck. In the limit, the external thread section 2-4 of the triangular shaft 2 can be connected with the arc-shaped convex rib drill rod 4; The cross-sectional shape and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com