Online program updating method for hydraulic support controllers

A technology of hydraulic inter-rack and controller, which is applied to program control device, program loading/starting, earthwork drilling, etc., can solve the huge workload, affect the efficiency of coal mining, and find a convenient and fast implementation method for program upgrade, etc. problems, to avoid workload and save program download time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A method for online program upgrade of a hydraulic rack controller according to the present invention will be further described in detail below with reference to the accompanying drawings.

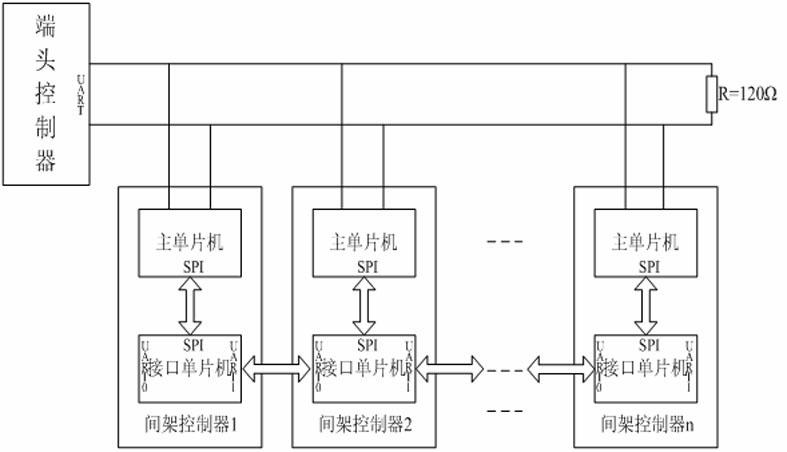

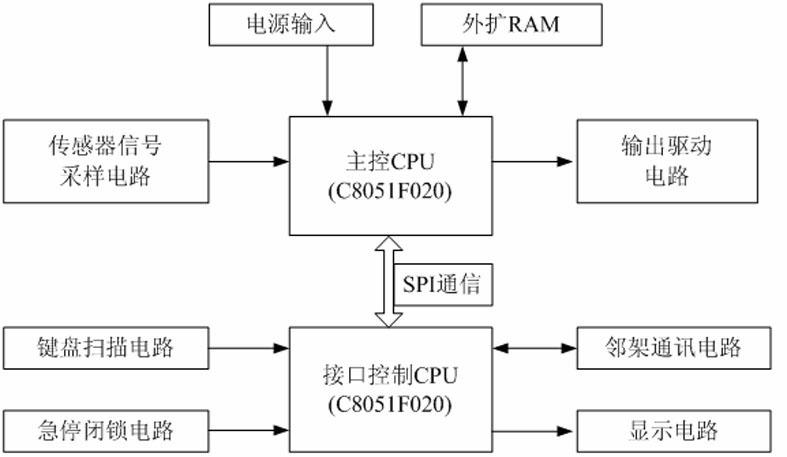

[0016] On the basis of the hardware platform of the present invention, such as figure 1 Shown: All hydraulic inter-frame controllers on the working face are connected sequentially through RS-485 inter-frame communication, as shown in figure 2 The internal hardware of the shown hydraulic rack controller includes a main control part and an interface control part. The main control part and the interface control part of the hydraulic rack controller adopt the SPI master-slave communication mode, the interface part is the master, and the master control part is the slave.

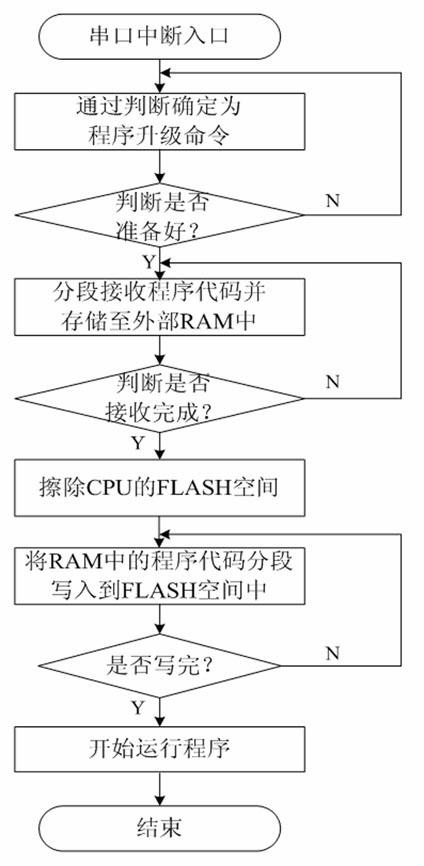

[0017] The program flow chart of the specific implementation of the online upgrade function of the hydraulic rack controller program described in the present invention is as follows image 3 As shown, the terminal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com