Method for gas drainage from high-position roadway coal seam containing shielded soft rock

A coal seam gas, high-level technology, applied in the field of coal mining, can solve the problems of unsatisfactory gas drainage effect of shielded soft rock, and achieve the effect of convenient drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A coal seam gas drainage method with shielding soft rock, the steps are as follows:

[0022] The first step: construction of high lane

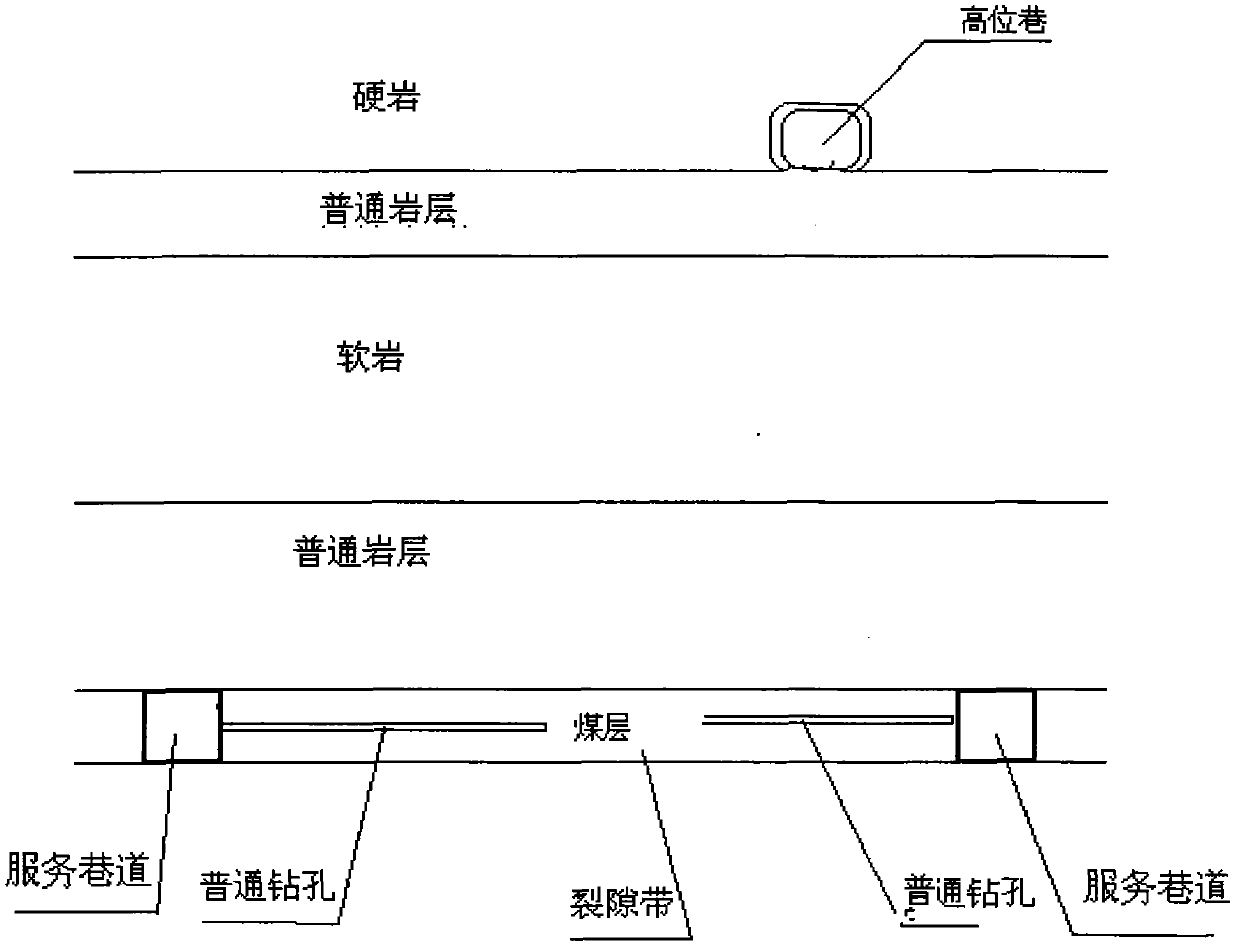

[0023] Before the coal seam is mined, the roadway is developed in the hard rock layer of the coal seam roof. Because it is designed on the top of the coal seam, it is called the high-level roadway. The developed roadway must ensure the stability of the surrounding rock and strengthen the temporary support. The layout of the high-level roadway is as follows figure 1 shown;

[0024] Step 2: Conventional Drilling and Drainage

[0025] During the mining of the working face, first of all, conventional drilling is drilled into the coal seam in the service roadway of the working face for preliminary gas drainage. The drilling layout is as follows: figure 1 shown;

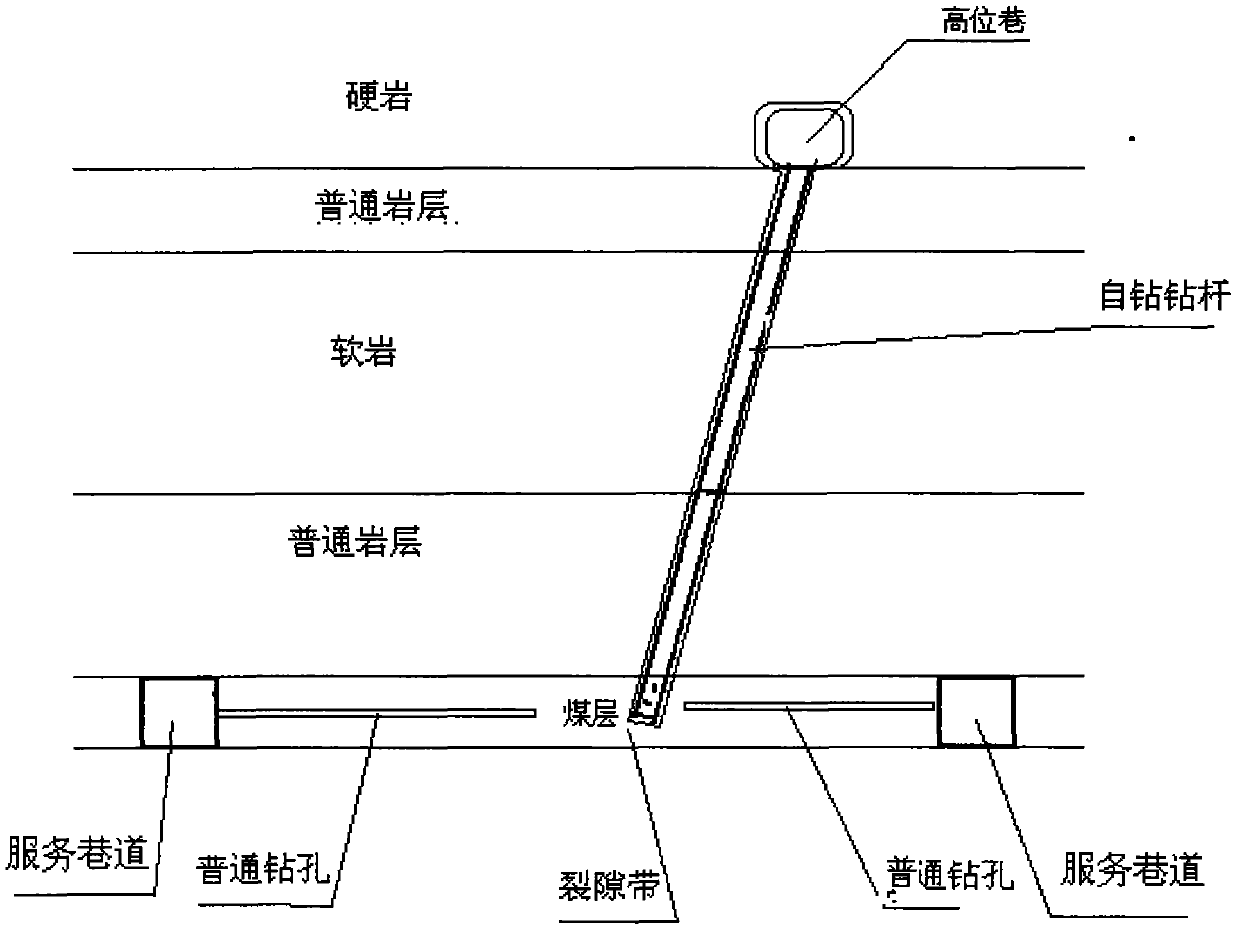

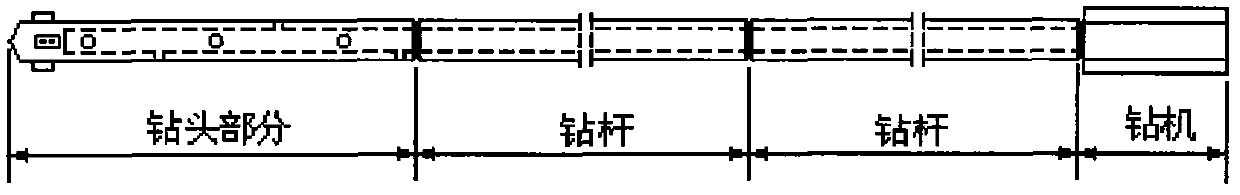

[0026] Step 3: While initially draining the gas, drill holes into the coal seam in the high-level roadway on the roof. When drilling, a self-drilling drill pipe with a hollow st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com