Drill chuck with positioning device

A technology of positioning device and drill chuck, which is applied in the direction of manufacturing tools, tool holder accessories, chucks, etc., can solve the problems of poor flexibility of drill chuck, easy to reduce precision, low assembly efficiency, etc. Product cost, simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

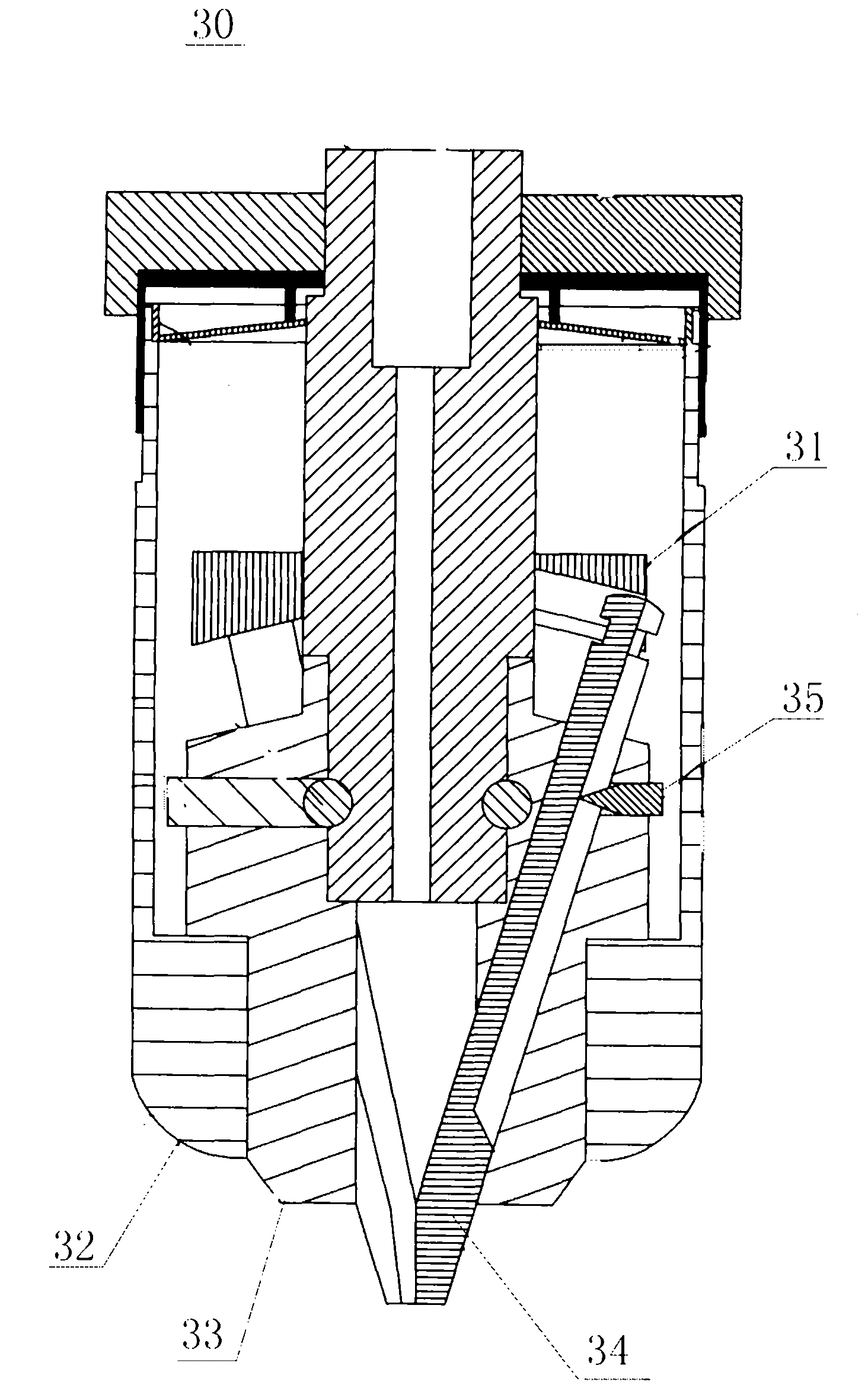

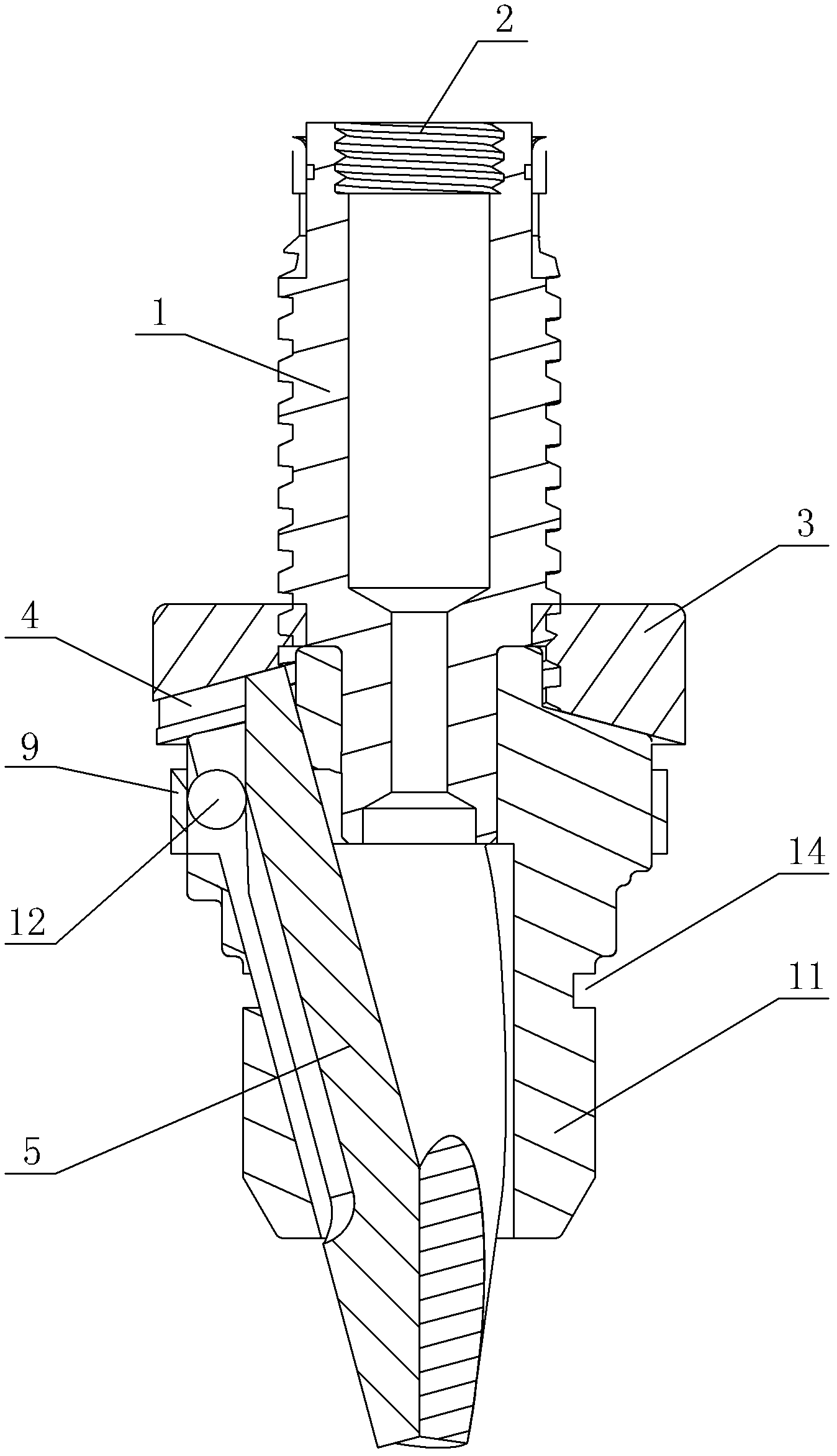

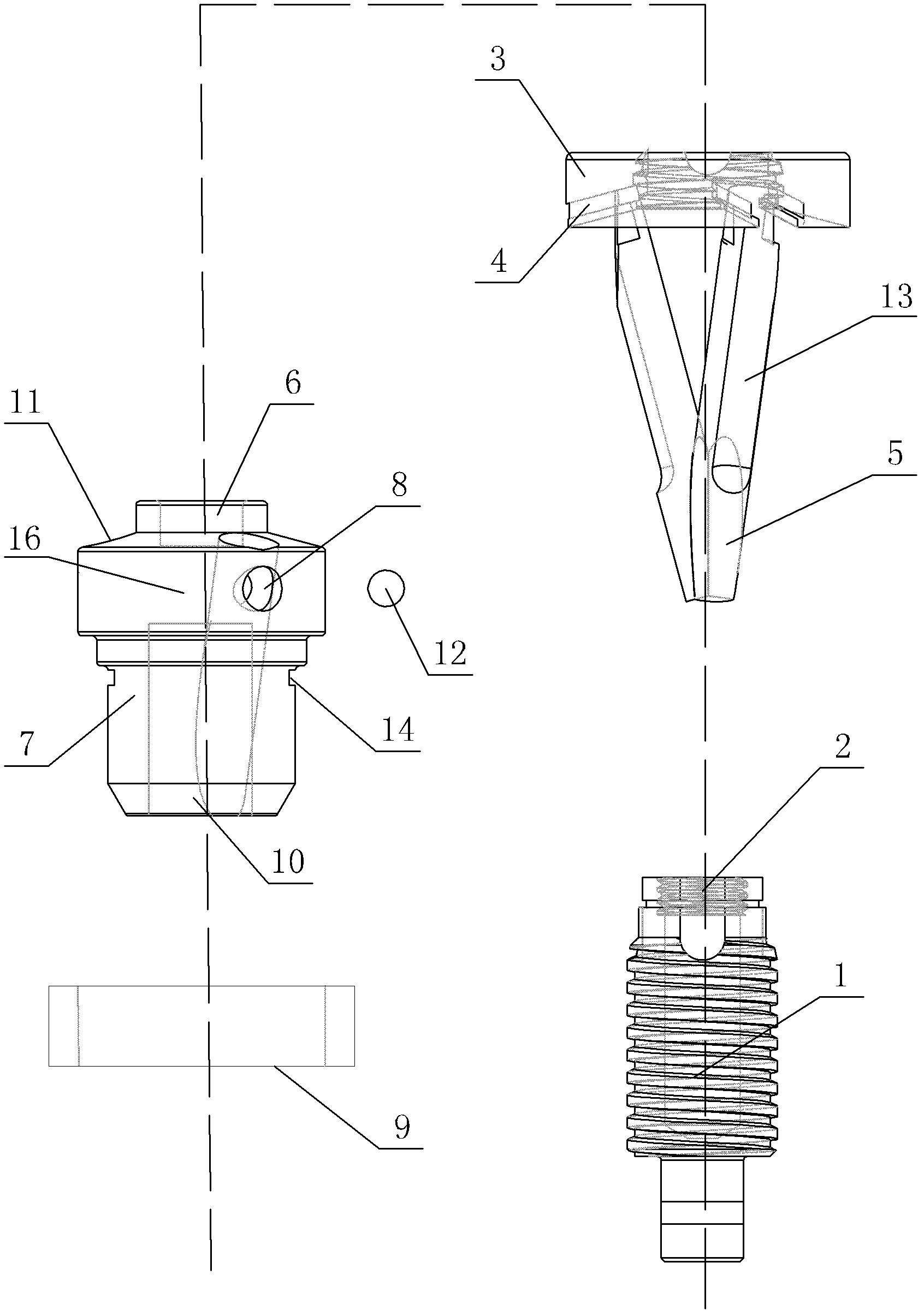

[0017] Such as figure 2 and image 3 As shown, the drill chuck body 11 is obliquely and symmetrically processed with three jaw holes 7 penetrating up and down, and three ball holes 8 are provided at the upper end of the drill chuck body 11 corresponding to the three jaw holes 7, and the lower end Along the central axis of the drill chuck body 11, a tool hole 10 larger than the maximum applicable tool assembly outer diameter is processed, and the upper end of the push screw 1 is processed with a host connection that matches the transmission shaft of the equipment host that assembles the self-tightening drill chuck. Hole 2, the upper end of the drill chuck body 11 is processed with a connecting hole 6 matching the outer diameter of the lower end of the push screw 1 along the central axis, and the lower end of the push screw 1 is movably sleeved in the connecting hole 6, and the connecting hole 6 and the tool hole 10 is provided with a partition 16, so that the two are not conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com