Track type dredger installation structure

A technology of installation structure and dredger, which is applied in the field of mining machinery, can solve the problems of not being durable, heavy hydraulic device load, and shortened service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

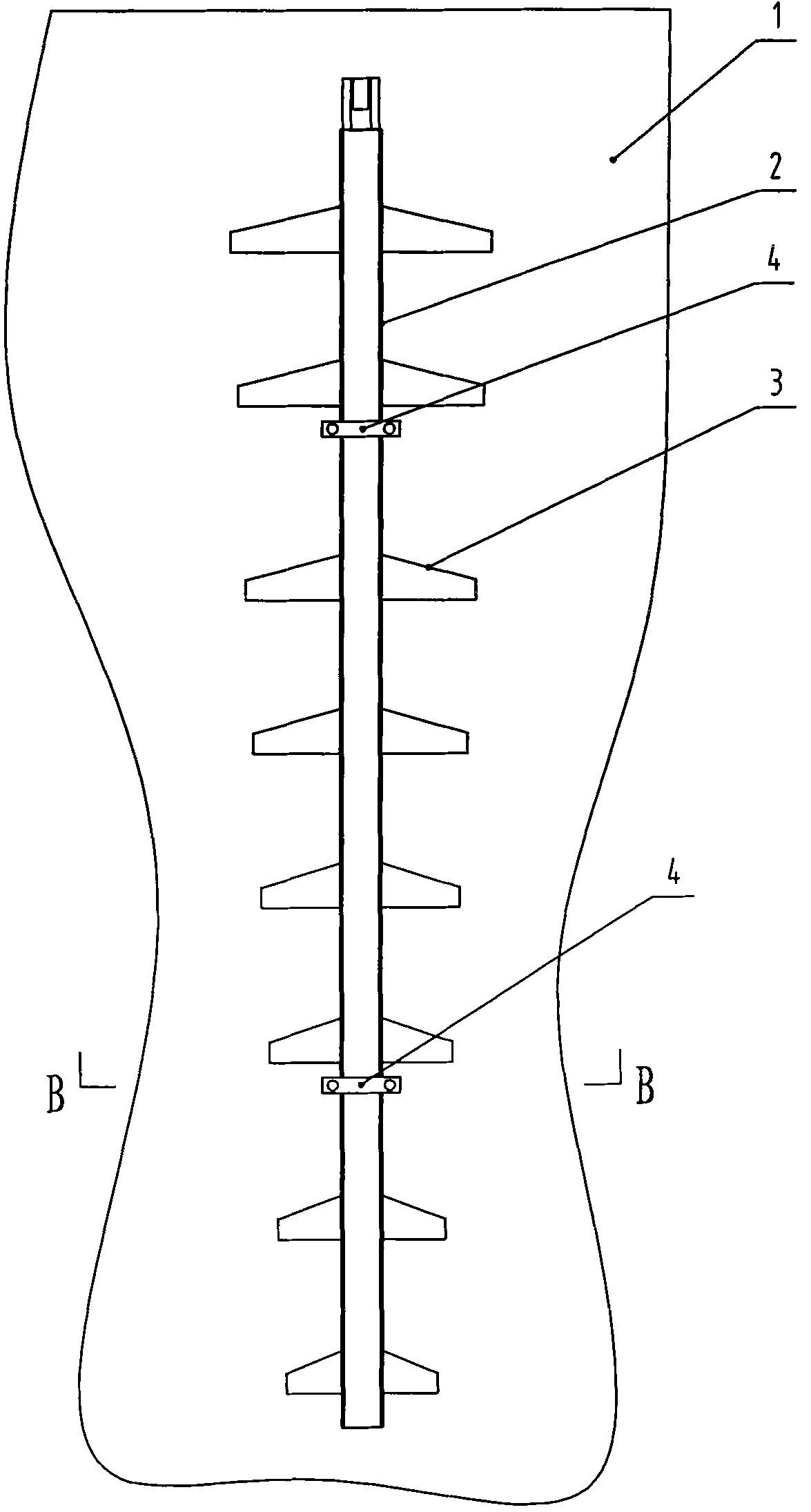

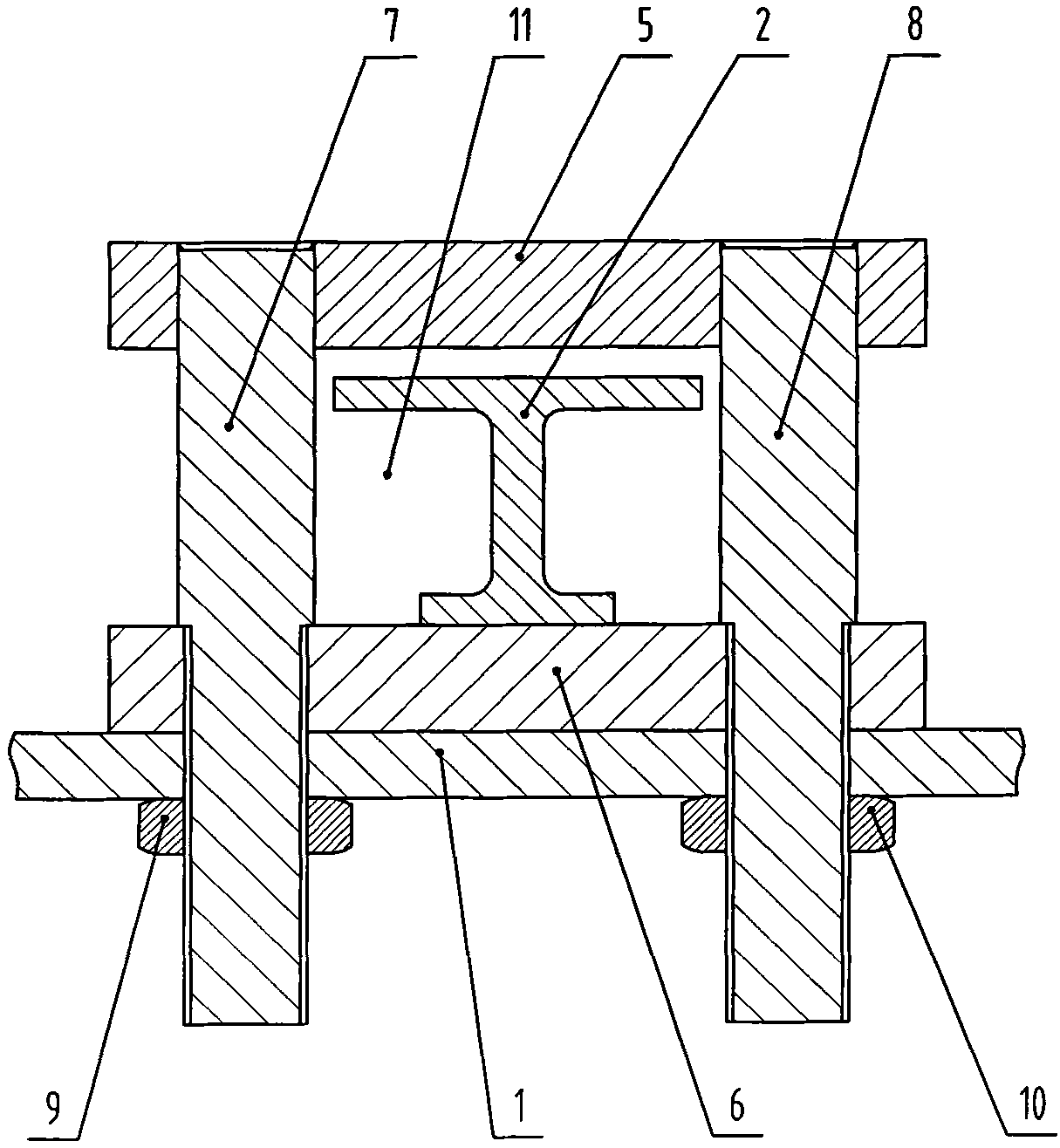

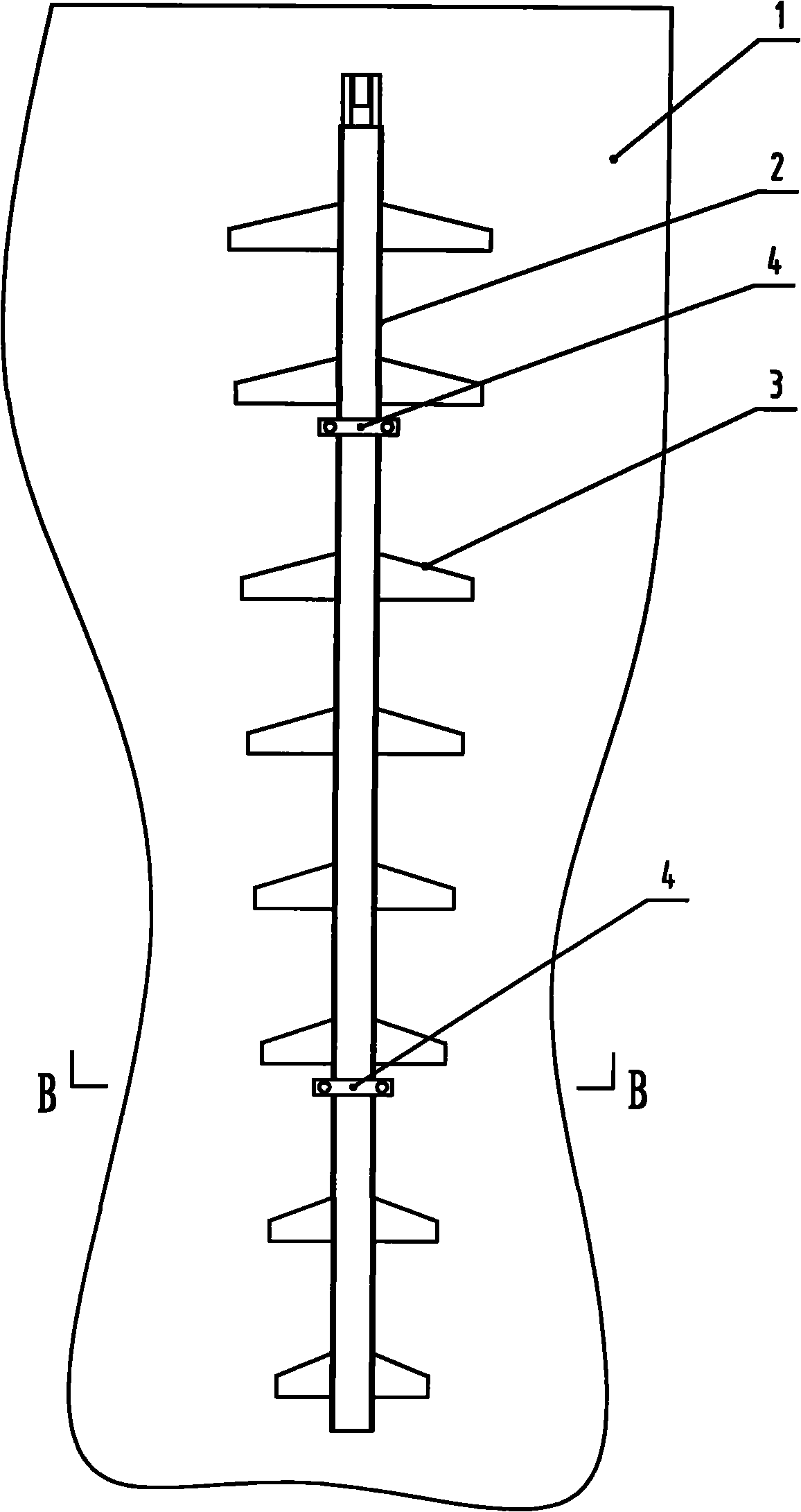

[0011] Such as figure 1 and figure 2 As shown, the installation structure of the track-type dredger of the present invention includes a silo 1, a tie rod 2 is vertically arranged in the hopper 1, and a plurality of scrapers 3 are arranged horizontally on the pull bar 2 axially, and each scraper 3 is about the pull rod. The axis of 2 is symmetrical, the length of each scraper 3 in the horizontal direction is gradually shortened from top to bottom, the vertical distance between two adjacent scrapers 3 is equal, and the connection line between the ends of the same side of each scraper for a straight line. The inner wall of the silo 1 is provided with a limiting device 4, the limiting device 4 includes a clamping plate 5, a clamping plate 6, a bolt 7 and a bolt 8, the clamping plate 5 and the clamping plate 6 are arranged in parallel, the bolt 7 and the bolt 8 are arranged in parallel, and the clamping plate 5 Set vertically with the bolt 7, the same end of the bolt 7 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com