Unloading frame of cutting machine with automatic unloading function

An automatic unloading and material cutting machine technology, applied in the field of unloading racks, can solve the problems of reducing the processing efficiency of plastic parts and increasing equipment costs, and achieve the effect of reducing equipment costs and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

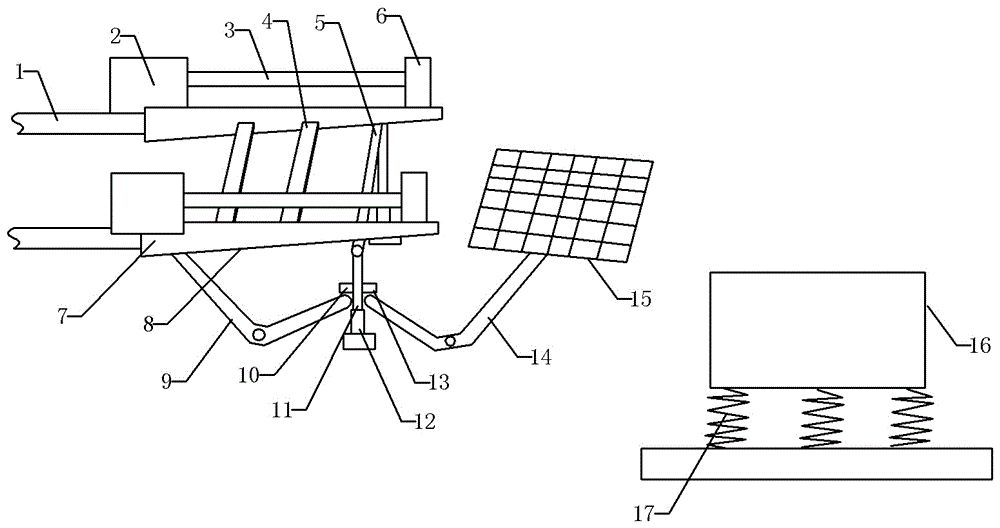

[0017] The reference signs in the drawings of the description include: guide rail 1, cylinder 2, piston rod 3, support plate 4, delivery rod 5, connection seat 6, delivery rail 7, inclined plane 8, first swing rod 9, first protrusion 10 , pillar 11, sleeve 12, second protrusion 13, second swing rod 14, transmission member 15, receiving plate 16, support spring 17.

[0018] as attached figure 1 As shown in the unloading frame of the cutting machine with automatic unloading function, two guide rails 1 are fixed horizontally and parallelly, and each guide rail 1 is provided with a conveying rail 7 that can slide along the length direction of the guide rail 1, and the guide rail 1 is used for guiding when the conveyor rail 7 moves. The end of the delivery rail 7 away from the guide rail 1 is provided with a connecting seat 6, the connecting seat 6 is fixed to the end of a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com