Paint-free ecological plywood made of poplar base materials and production process for paint-free ecological plywood

A kind of plywood and ecological technology, applied in the field of plywood, can solve the problems of poor gluing performance, not broad market prospect, low production efficiency, etc., and achieve the effect of good surface calmness, as-new quality and easy care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with the embodiments.

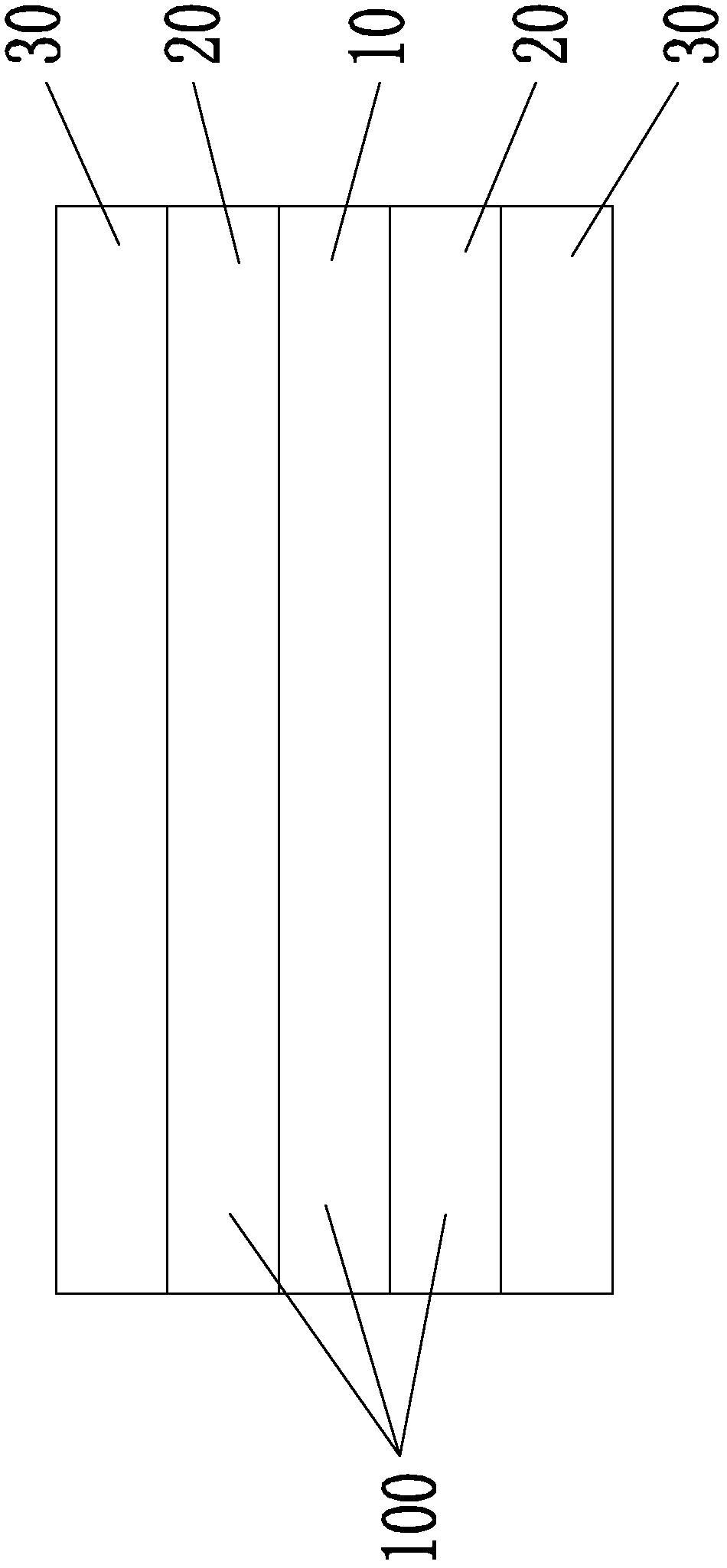

[0026] refer to figure 1 , a kind of poplar wood-based paint-free ecological plywood, which includes a plywood 100 made of poplar wood-based material, and impregnated decorative paper 30 is provided on the upper and lower sides of the plywood 100 . The plywood 100 includes a superimposed middle board 10 and veneers 20 arranged on both sides of the superimposed middle board 10 , and the above-mentioned decorative papers 30 are respectively arranged on the outer sides of the corresponding veneers 20 .

[0027] A kind of production technology of the paint-free ecological plywood of poplar base material, the making of this plywood 100 comprises the following steps:

[0028] ① Plywood group blank; ② Plywood group blank coated with adhesive and hot pressing, when applying adhesive and hot pressing on plywood group blank, the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com