Vibration device of segment mould

A vibrating device and mold technology, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of bulkiness, easy welding and cracking of structural parts, restrictions on integrated flow production and improvement of production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

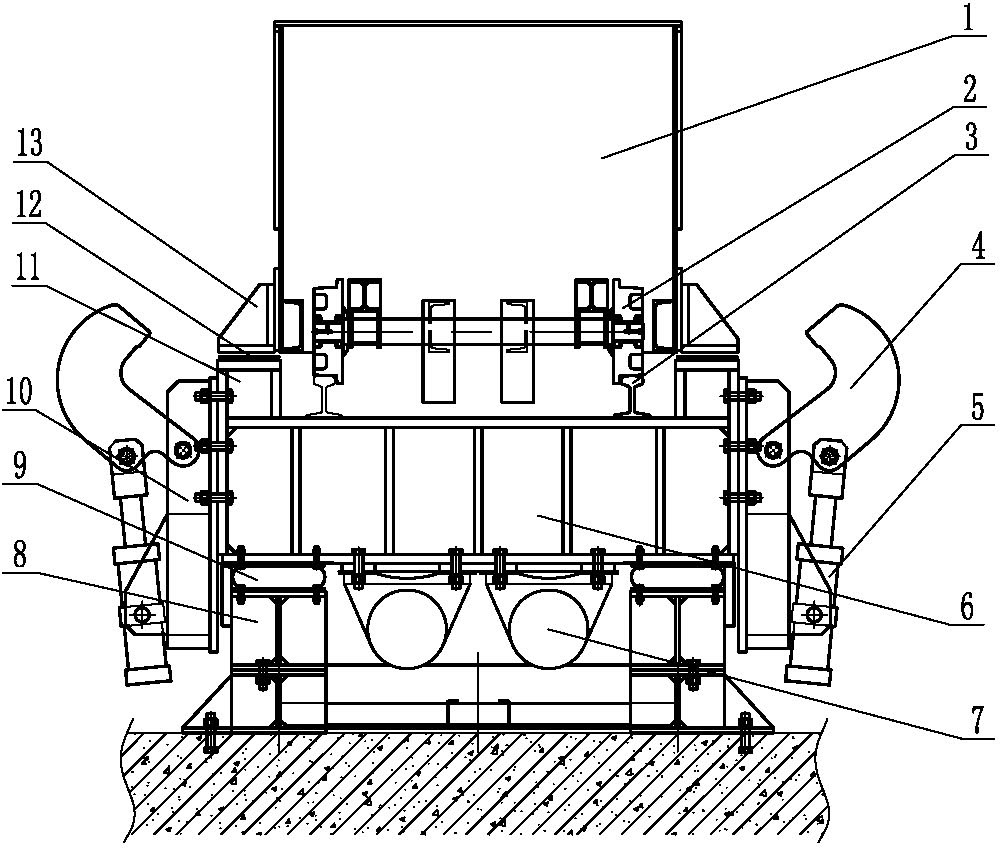

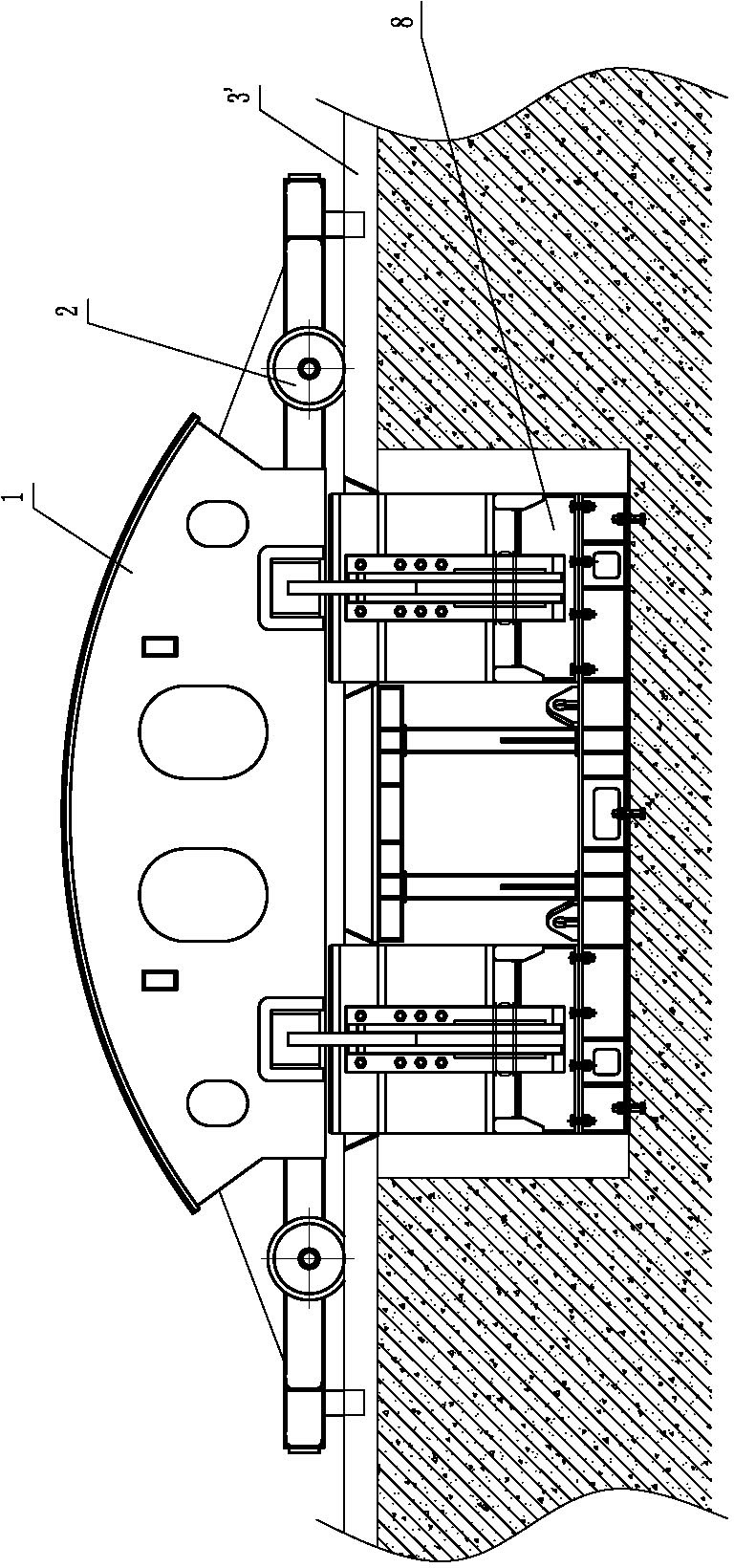

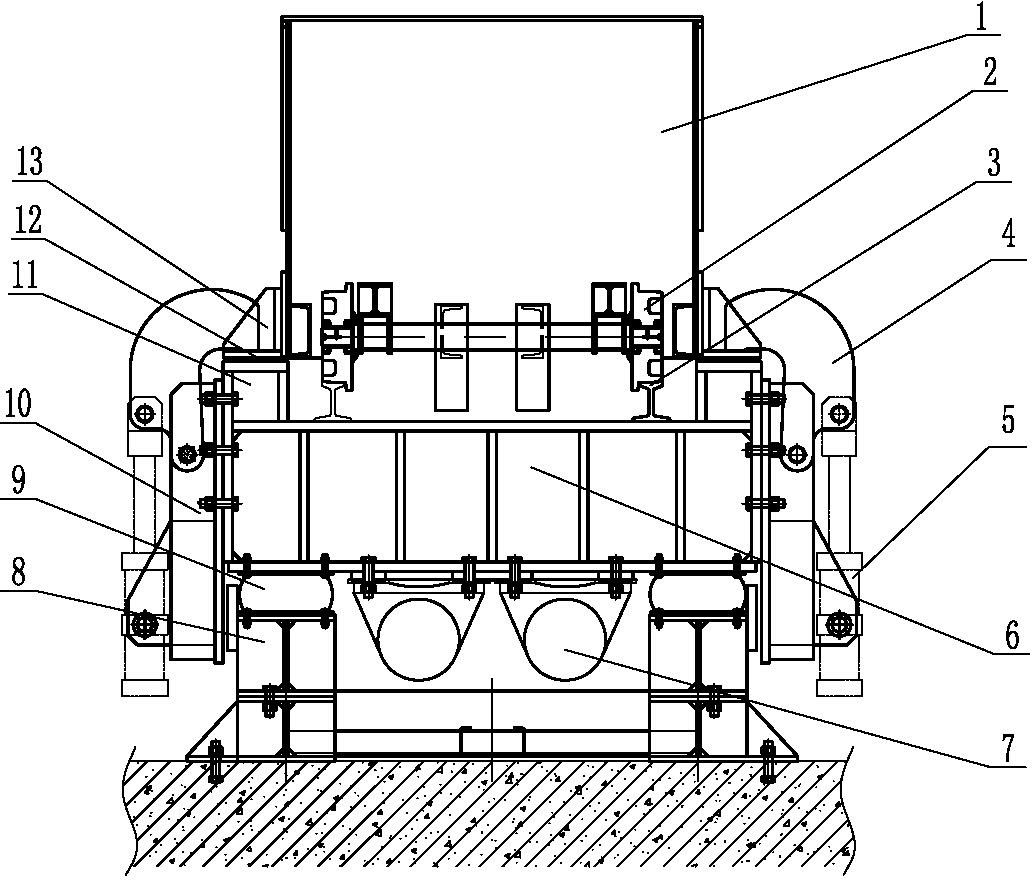

[0018] Such as figure 1 — Figure 4 Shown is the vibrating device of the segment mold of the present invention, comprising a vibrating table 6, which is driven by a vibrating motor 7, and two parallel guide rails 3 for the circulation of the segment mold 1 are arranged on the vibrating table 6, during installation , the guide rail 3 must be continuously connected with the guide rail 3' for the process flow of the production line to ensure the flow of the segment mold 1 on the production line. An installation base 8 is provided, and the installation base 8 is fixed to the installation ground by embedded bolts. An air bag 9 for support is provided between the installation base 8 and the vibrating table 6, and an air bag 9 for supporting is provided on the vibrating table 6 when the vibrating table 6 vibrates. The supporting parts of the segment mold 1 are propped up, and the side of the vibration table 6 is provided with a clamping mechanism for fixing the segment mold 1; where...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap