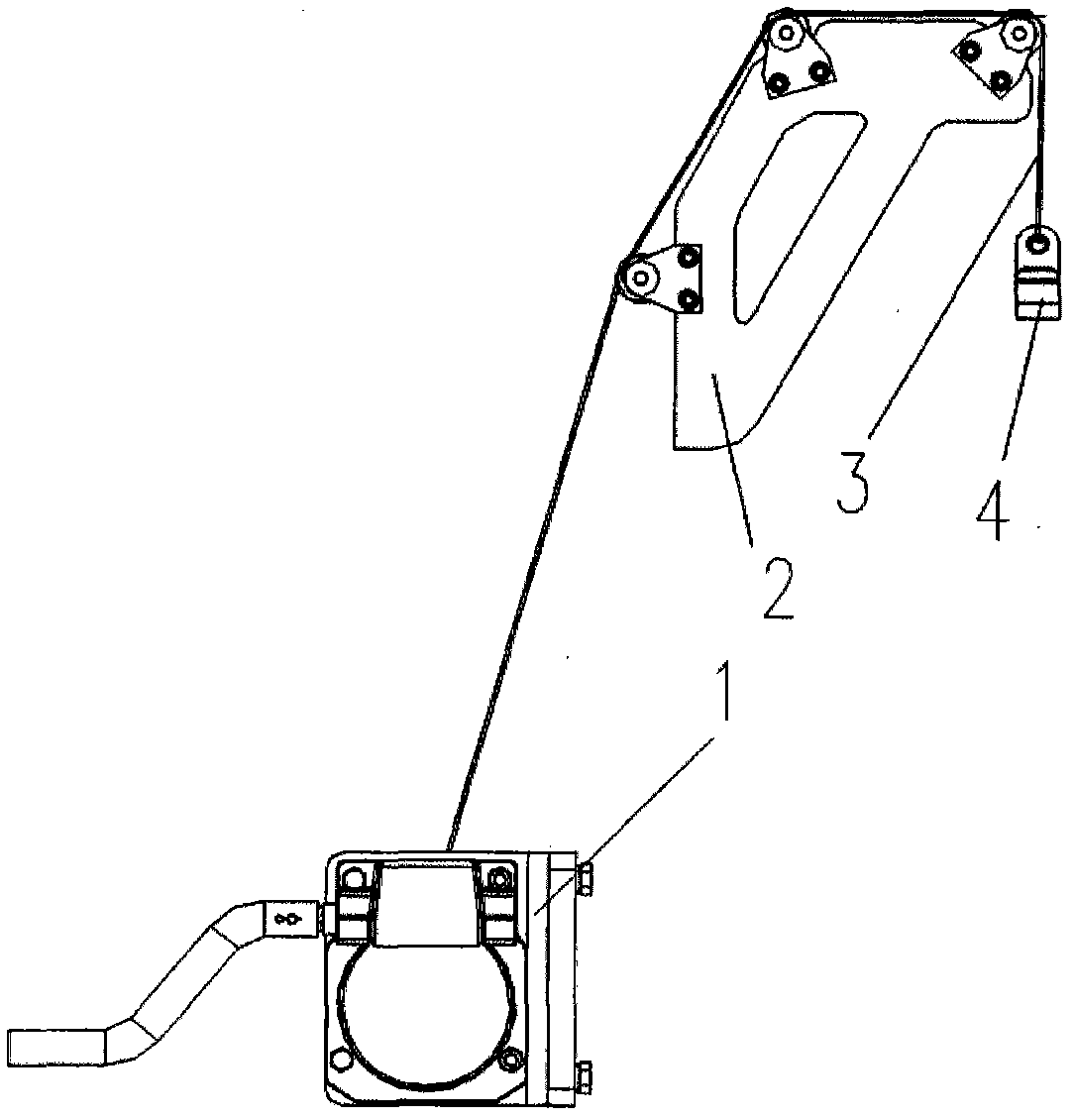

Lifting device for spare tires of special military and police vehicles

A special vehicle and hoisting device technology, applied in spare tire arrangement, vehicle parts, transportation and packaging, etc., can solve problems such as difficulty in changing tires, and achieve the effect of increasing the hoisting range and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

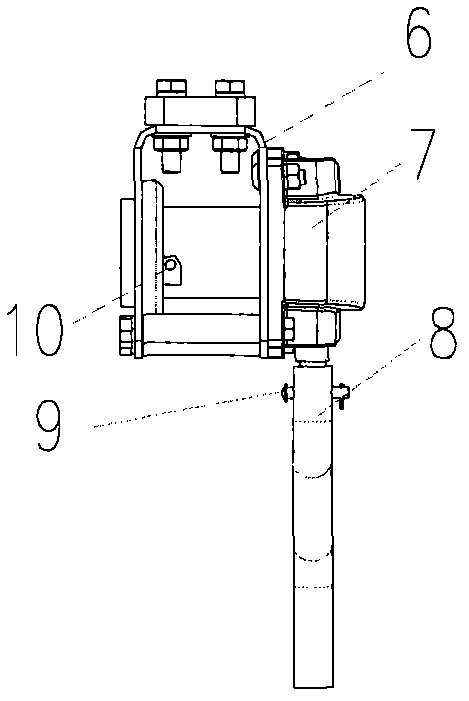

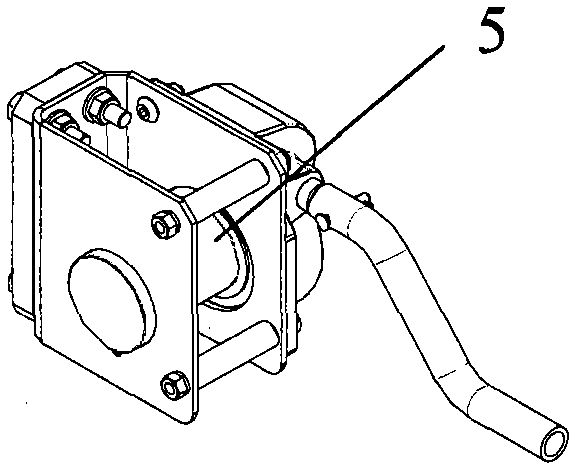

[0014] A spare tire hoisting device for military and police special vehicles, which consists of a labor-saving winch 1, a rotatable hoisting arm 2, a wire rope 3 and a hook 4. Handle 8 is formed, and worm gear mechanism 7 is housed on the support 6, and one end of worm is connected with detachable rocking handle 8, and detachable rocking handle 8 is connected with worm with pin 9. The turbine is connected to and drives the rotating shaft 5. The rotating shaft 5 is provided with a wire rope joint 10 for fastening one end of the wire rope 3. The other end of the wire rope 3 is connected to the hook 4. The rotatable hoisting cantilever 2 is composed of a cantilever body 11, a pulley 12 and a rotating shaft 13. Composition, three pulleys 12 are installed on the cantilever body 11, are used for installing the middle part of wire rope 3. The rotary shaft 13 is installed on the cantilever body 11, and the cantilever 11 can rotate 270° around the rotary shaft 13.

[0015] The labor-s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap