Picking and placing device of glass substrate

A pick-and-place device, glass substrate technology, applied in the directions of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of long time consumption, high probability of fragmentation, and difficulty in resetting the cassette, etc. High degree of automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

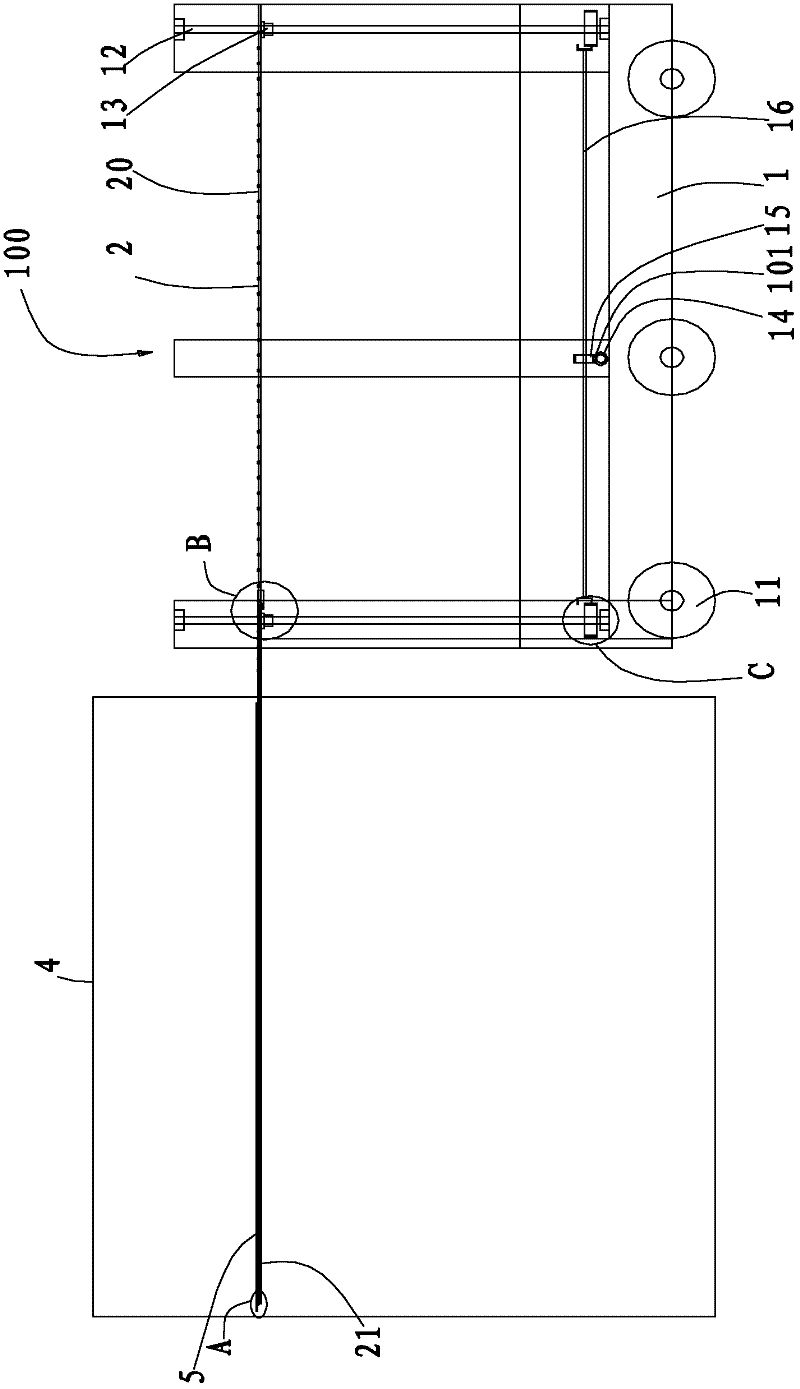

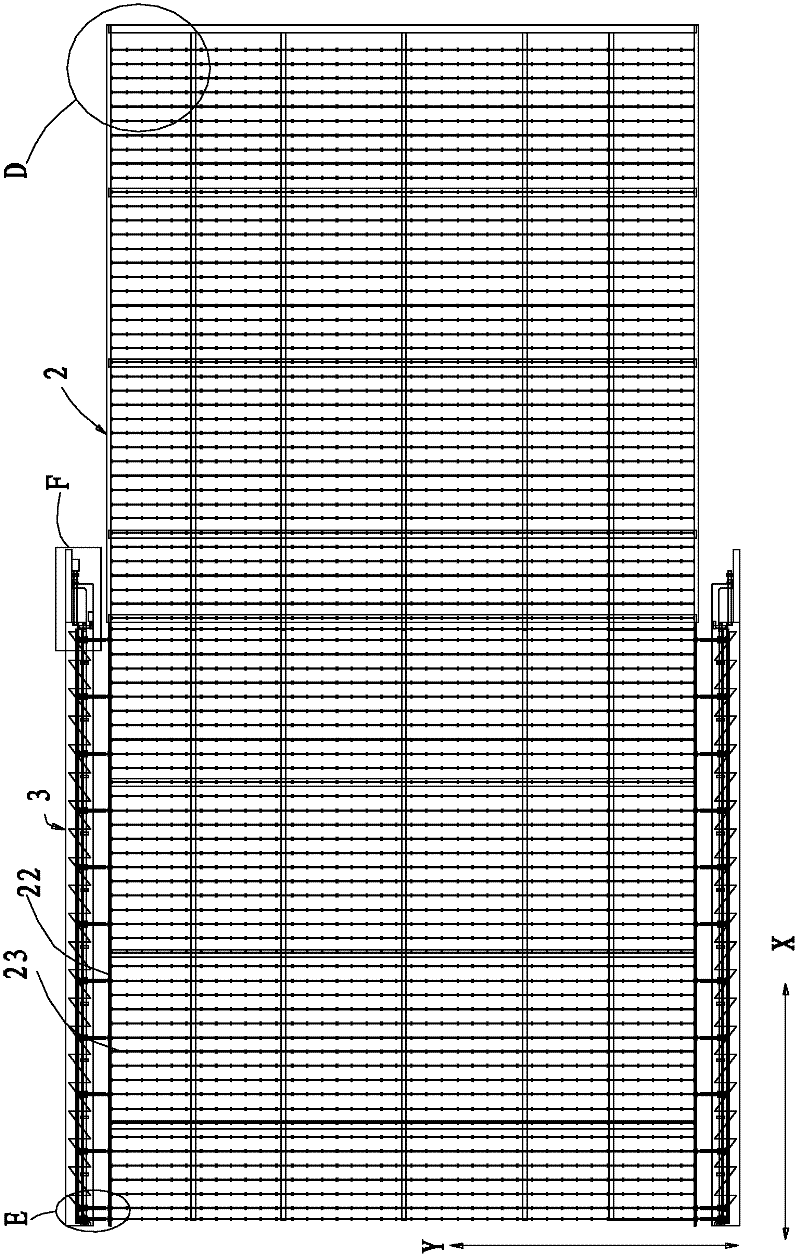

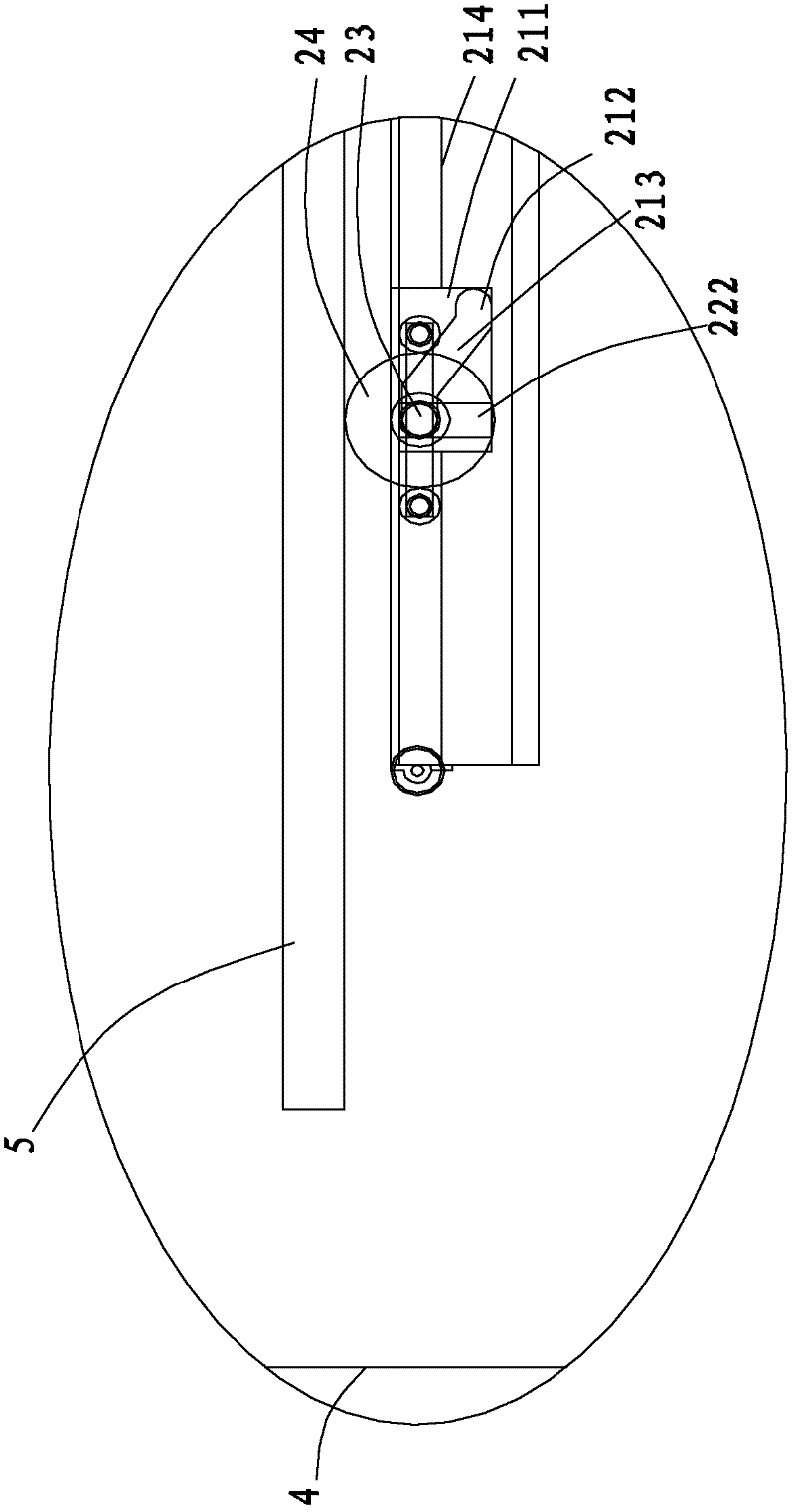

[0033] Please refer to Figure 1 to Figure 2 , the pick-and-place device 100 for glass substrates in the embodiment of the present invention includes a frame 1 and a transfer platform 2 . The transmission platform 2 is disposed on the frame 1 , and includes a transmission part 21 capable of entering and exiting the cassette 4 and a receiving part 20 adjacent to the transmission part 21 . The transmission part 21 includes a first frame 22 and a plurality of first transmission rods 23 arranged in parallel along the first horizontal direction X and supported by the first frame 22 .

[0034] The pick-and-place device 100 for glass substrates in the embodiment of the present invention further includes a horizontal translation mechanism 11 and a vertical translation mechanism. Wherein, the horizontal translation mechanism 11 is used to drive the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com