Automatic overturning device for maintenance operation of cylinder cover

A technology of automatic turning and cylinder head, applied in the direction of lifting device, etc., can solve the problems of consuming a lot of manpower and material resources, inconvenient maintenance work, heavy cylinder head weight, etc., to overcome the lack of maintenance space, reduce labor intensity, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

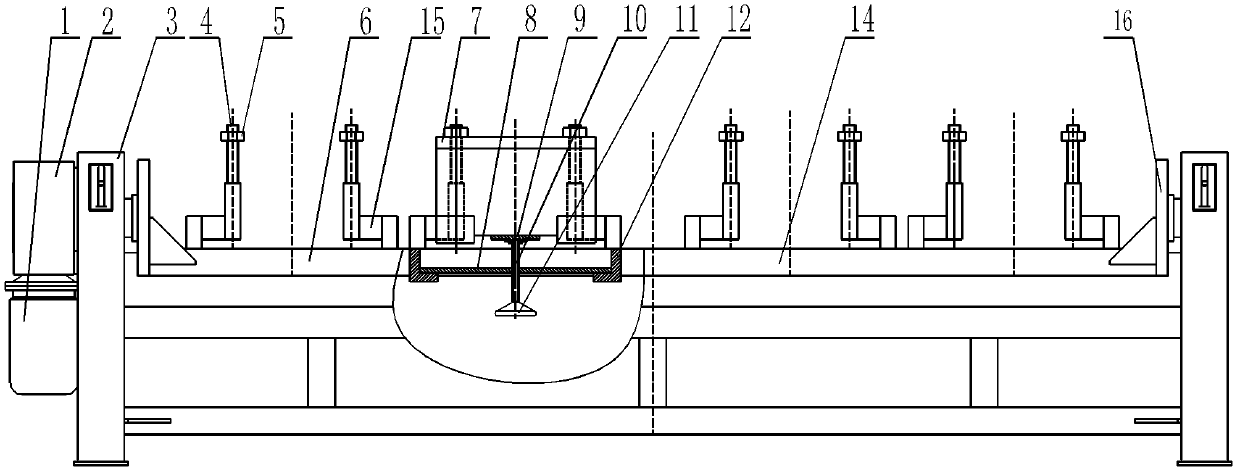

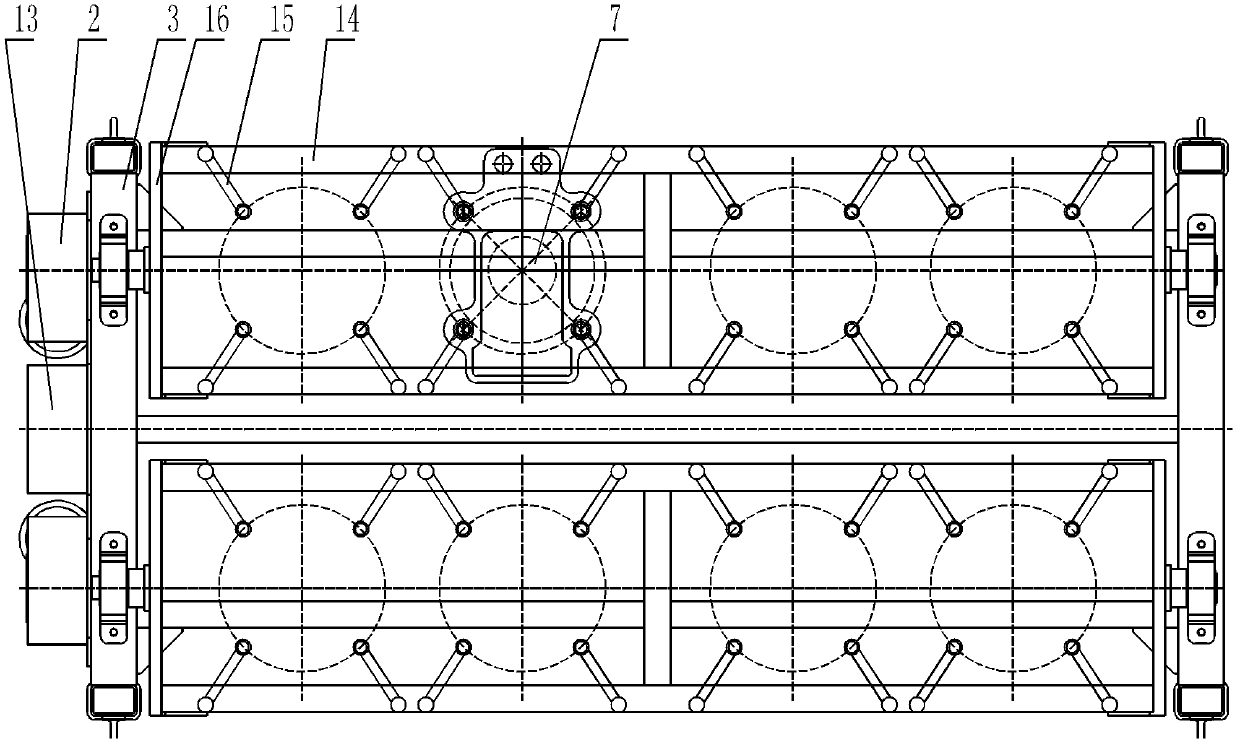

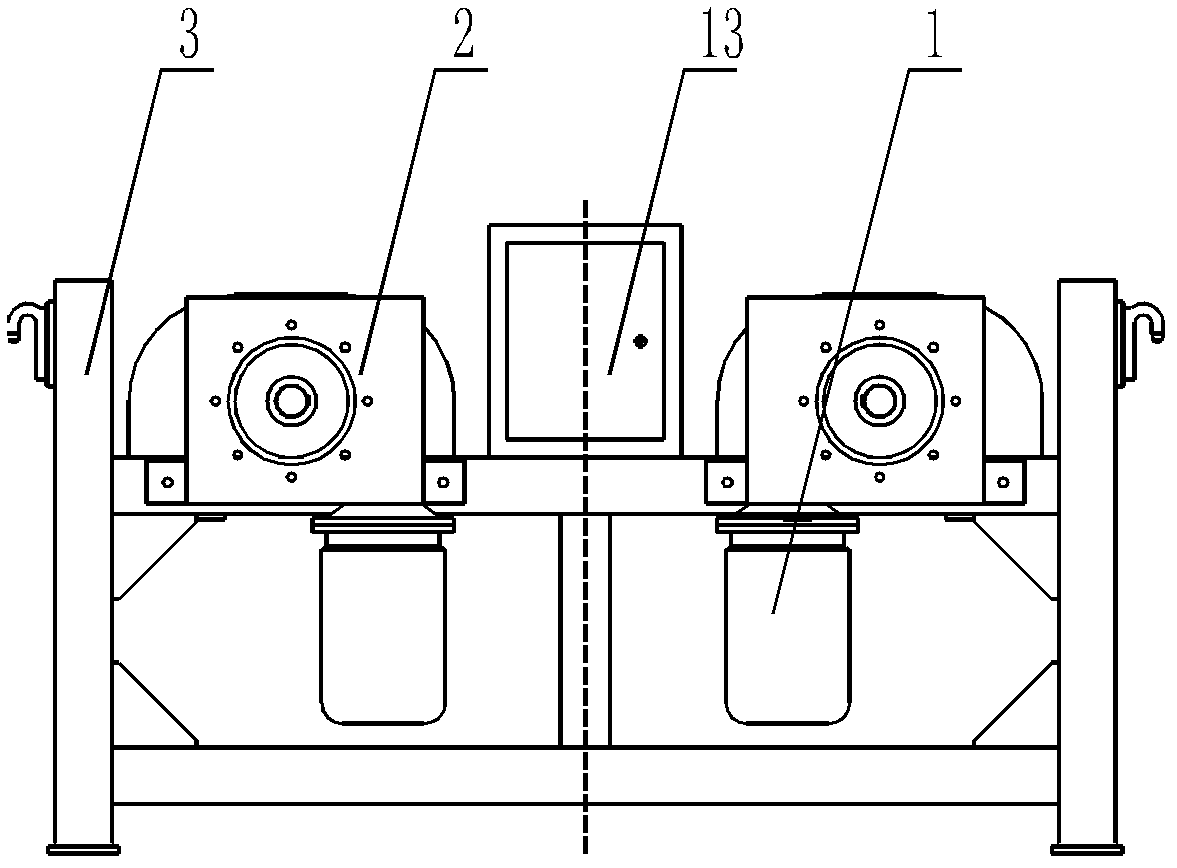

[0026] Such as figure 1 As shown, an automatic overturning device for cylinder head maintenance work, it includes a supporting support 3, two overturning mechanisms are arranged on the supporting support 3, and the overturning bracket 6 of each overturning mechanism includes two parallel fixed beams 14, fixed The beam 14 is located on both sides of the cylinder head 7 to be installed. The fixed beam 14 is provided with four cylinder head fixing parts. The two ends of the two fixed beams 14 are respectively connected with a fixed plate 16. The fixed plate 16 is provided with The shaft on the seat 3; the shaft on one side is also connected with the worm gear reducer 2, and the worm gear reducer 2 is connected with the motor 1 and the control box 13; each turning mechanism is connected with its own worm gear reducer 2 and the motor 1. Two motors 1 share o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com