Control method and control device of milling machine and milling machine

A technology of a control device and a control method, which is applied in the field of a milling machine, a control method and a control device for a milling machine, can solve the problems such as the hidden danger of the weight of a car body supported by a milling drum, so as to improve reliability and safety, and solve safety problems. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

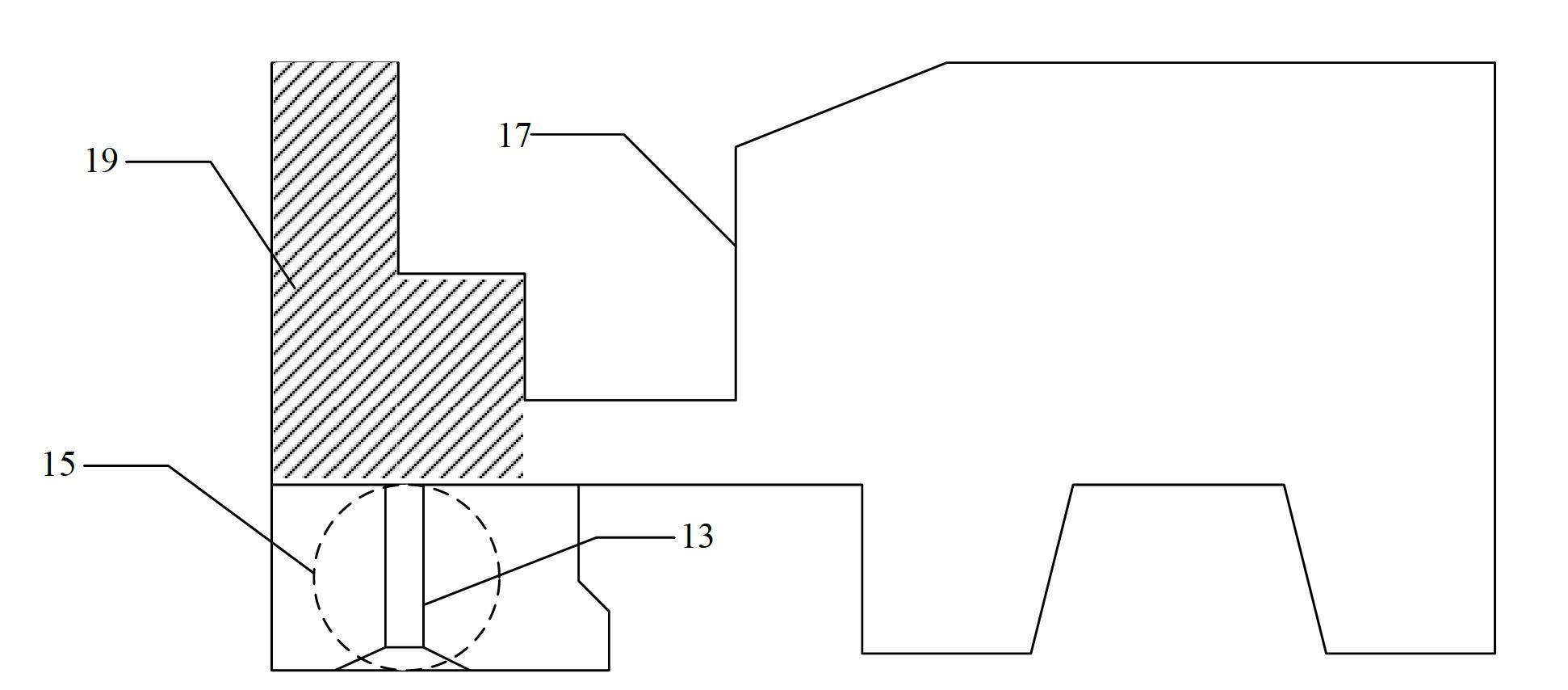

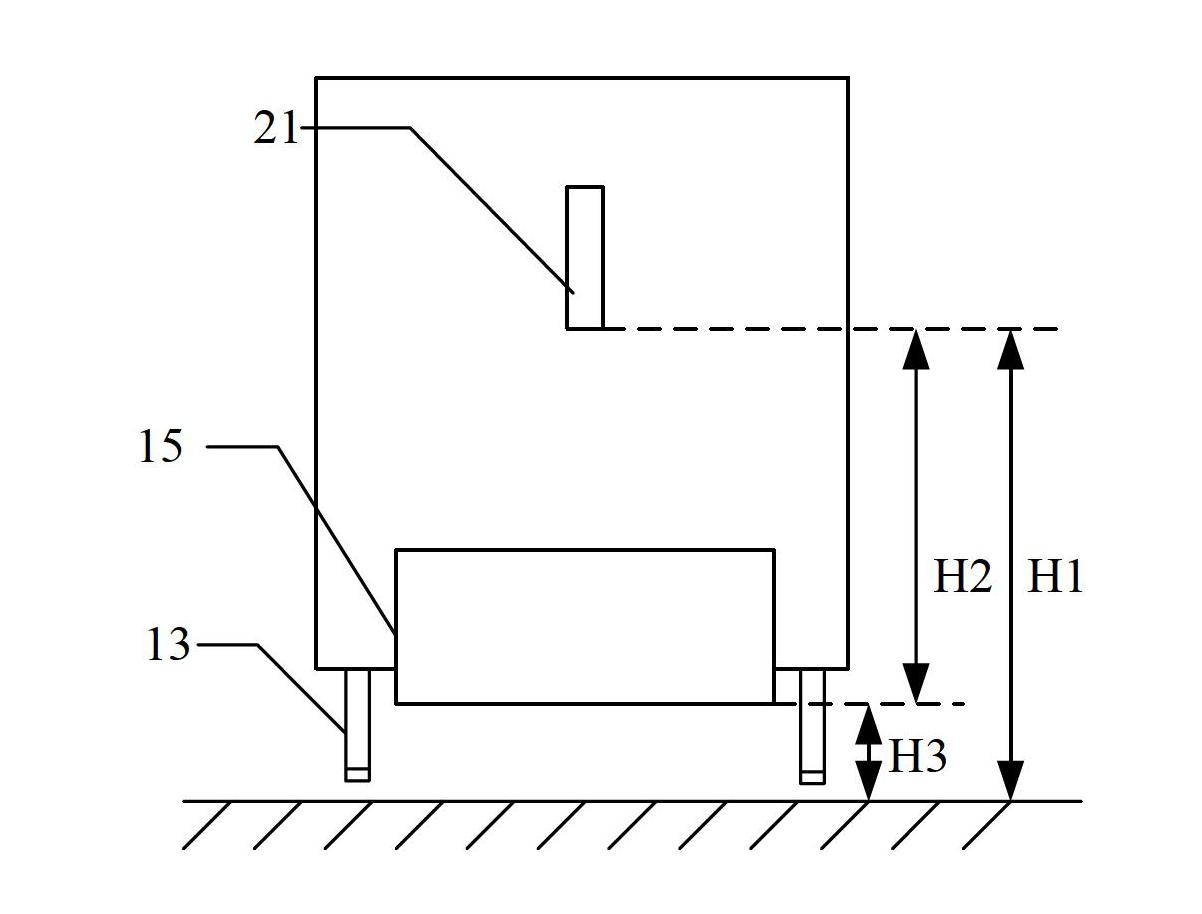

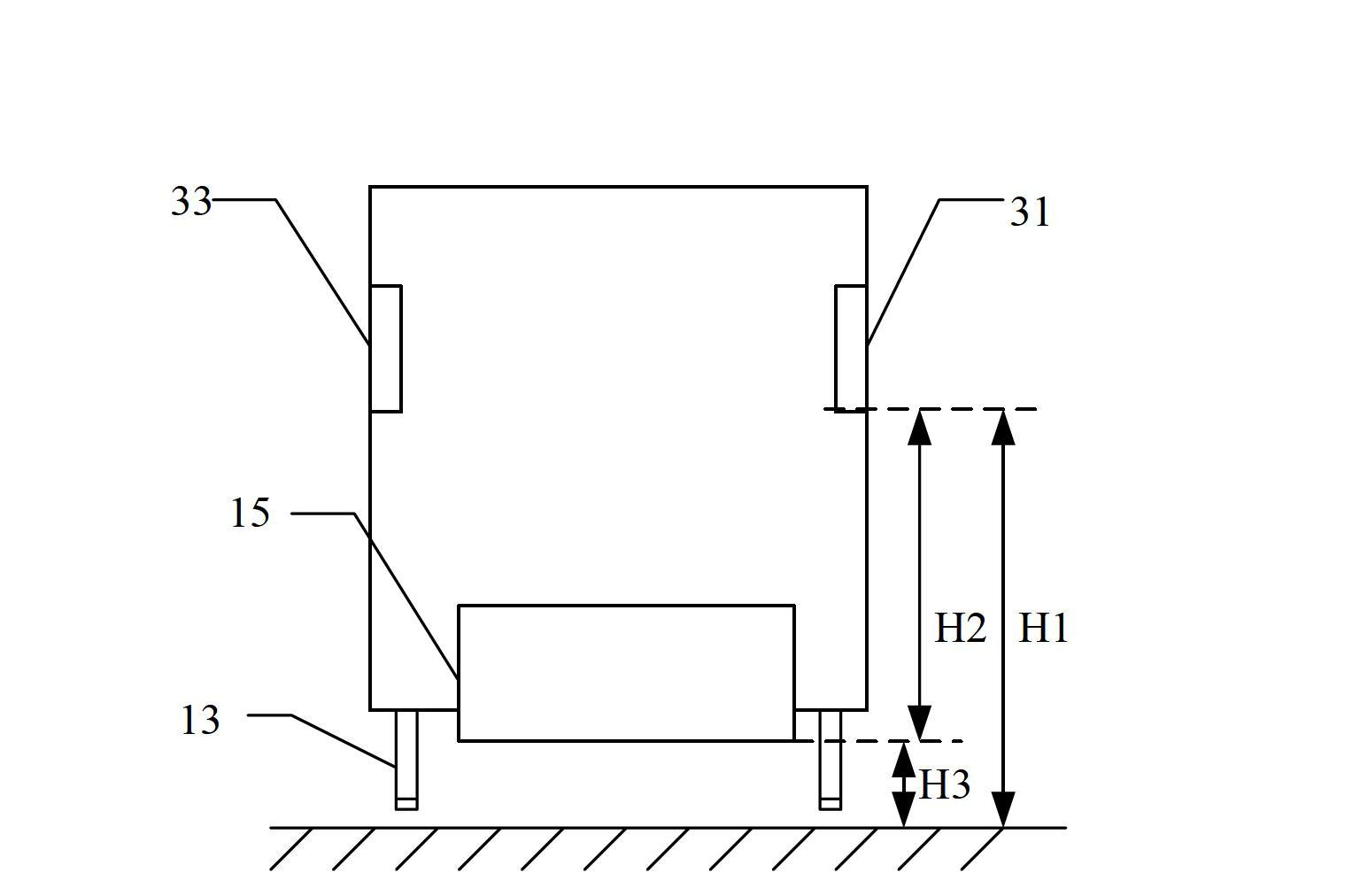

[0034] figure 1 It is a structural schematic diagram of a milling machine according to an embodiment of the present invention. As shown in the figure, the front outrigger and the rear outrigger 13 of the milling machine jointly support the vehicle body 17, and the milling drum 15 is arranged at the rear of the vehicle body 17. During the construction process Among them, under the drive of the driving mechanism of the rear legs, the rear legs 13 automatically descend, and the operator starts the milling drum 15, and the milling drum 15 descends following the lowering of the legs to mill the ground. The milling machine of the embodiment of the present invention is equipped with a distance measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com