Assembly structure of sound insulation wall of anechoic chamber

A technology for assembling structure and anechoic chamber, which is applied in the direction of sound insulation, wall, insulating layer, etc., can solve the problems of unsatisfactory sound insulation effect and the overall appearance of the anechoic chamber is not beautiful, and achieves ideal sound insulation effect, beautiful overall appearance and good sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

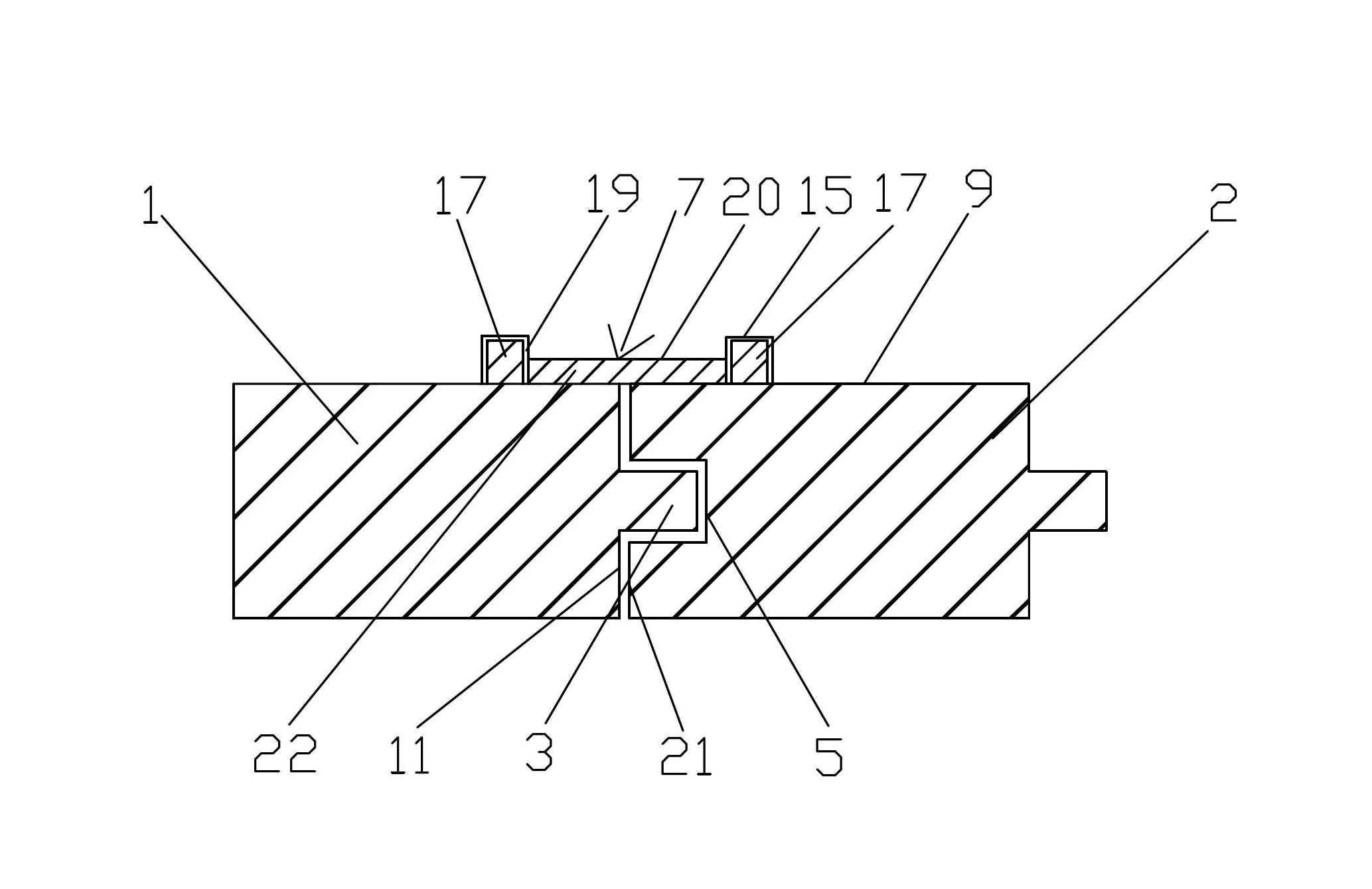

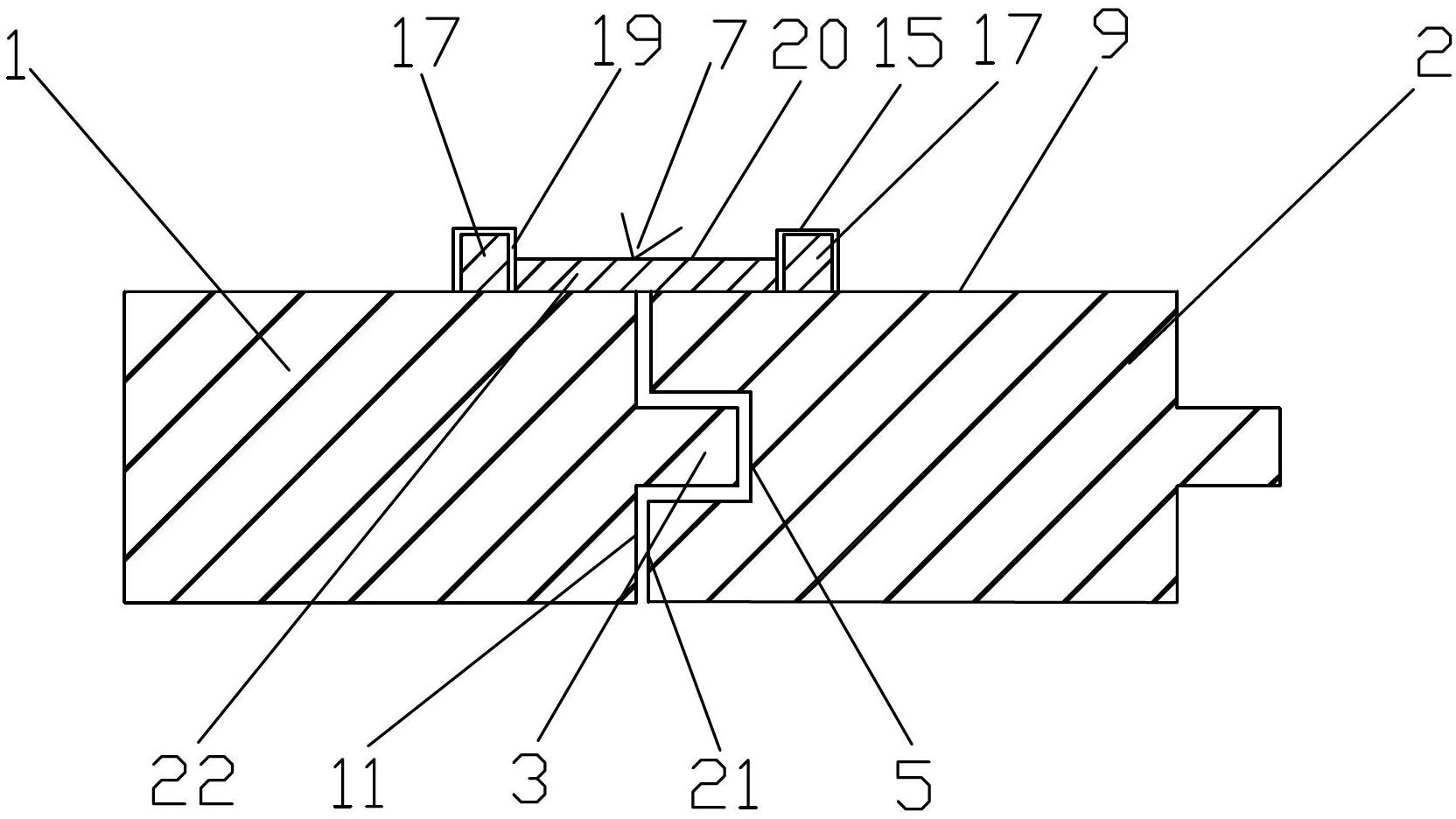

[0019] refer to figure 1 , an assembly structure of a sound-insulating wall of an anechoic chamber, which is arranged between two adjacent first and second sound-insulating walls 1 and 2 . The assembly structure includes a mating part 3, a mating part 5 mated with the mating part 3, and a sealing device 7, and the sealing device 7 is installed on the outer sides 9 of the first and second sound insulation walls 1 and 2 .

[0020] The matching part 3 is a protrusion extending outward from the middle part of the side 11 of the first sound insulation wall 1 , and the butt joint 5 is set on the adjacent side of the second sound insulation wall 2 . A groove on one side 21 of the first sound insulation wall 1, wherein the protrusion can be inserted into the groove.

[0021] In addition, the sealing devi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap