Transmission pipeline capable of monitoring leakage

A technology for conveying pipelines and leak detection, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of reliability, poor accuracy, difficult control and elimination, and large mutual interference of fluids. The effect of low labor cost, reduced labor, and less system investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

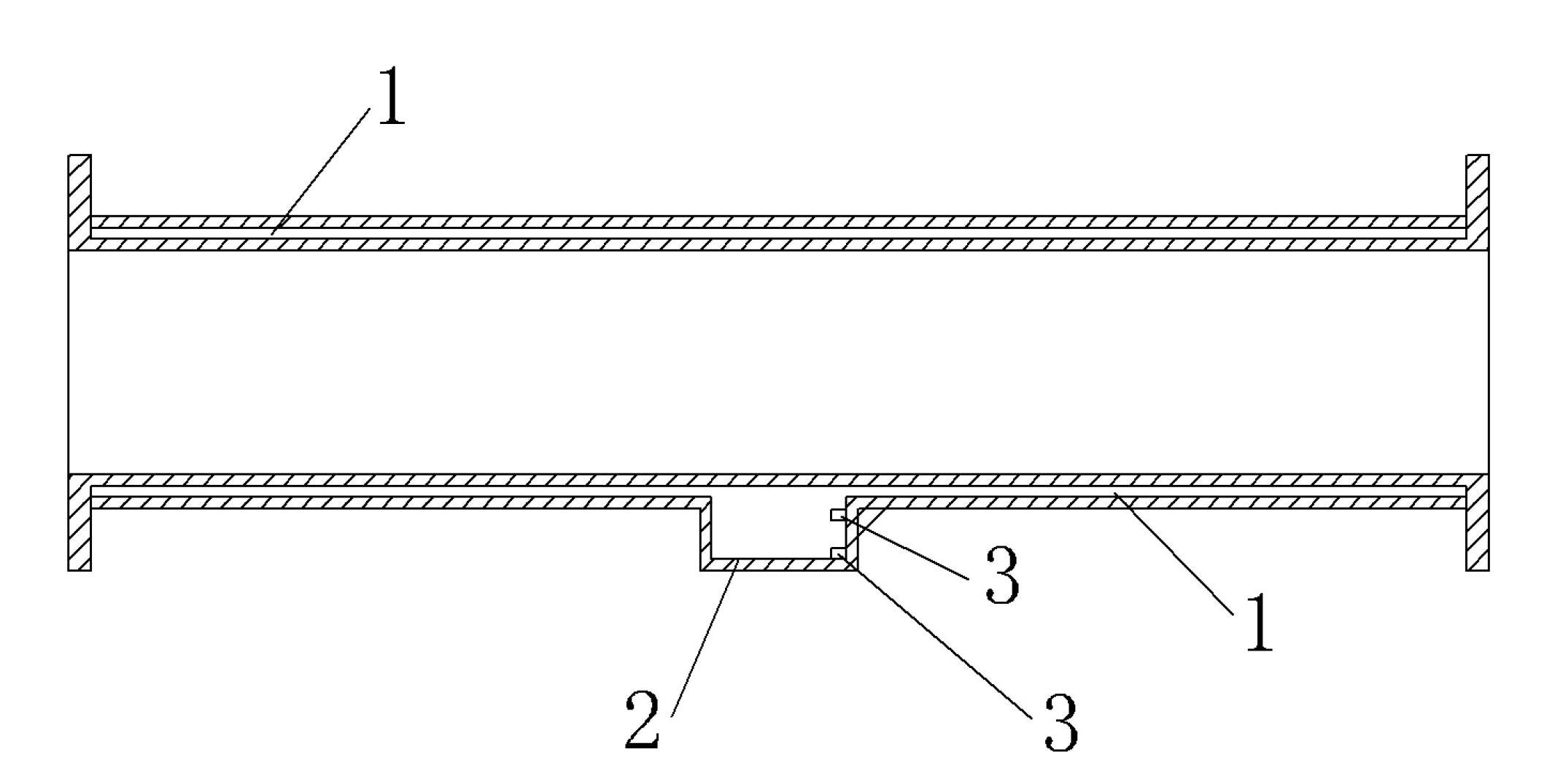

[0020] figure 1 It is shown that a specific embodiment of the present invention is a delivery pipeline that can monitor leakage, including multi-section pipelines connected to each other, and is characterized in that: the pipe wall of each section of the multi-section pipeline is sealed The interlayer 1 is equipped with a sensor 3 capable of detecting the delivered fluid in the sealed interlayer 1 .

[0021] The lower part of the sealed interlayer 1 of this embodiment is provided with a concave leak detection groove 2 , and the sensor 3 is installed in the leak detection groove 2 .

[0022] There are two sensors 3 in this embodiment, which are respectively installed at different heights of the leak detection tank 2 .

[0023] The sensor 3 of this embodiment is a sensor with sound alarm function.

Embodiment 2

[0025] The structure of this example is basically the same as that of the first example, the only difference is that the sensor 3 is a sensor with a display function, and its display part is set on the outer wall of the interlayer 1 . In this way, it is convenient for inspectors to read the detection data of the sensor, but it is necessary to perforate the outer wall of the interlayer and seal the perforation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com