Worm gear case of press machine

A technology for presses and worm gear boxes, which is applied in the field of presses, can solve the problems that the lubricating oil cannot be detected in real time, etc., and achieve the effect of solving the inability to real-time monitoring, simple control, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

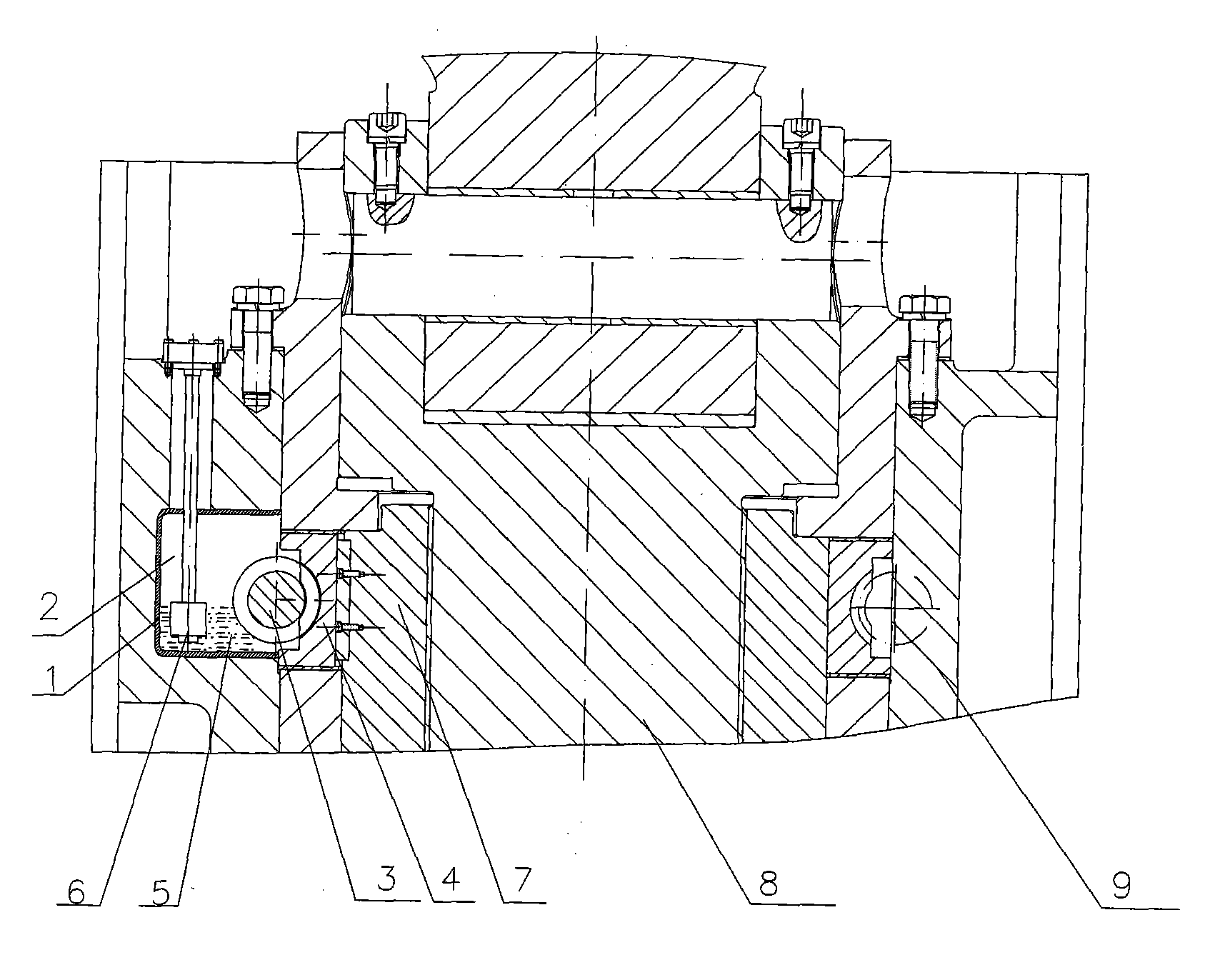

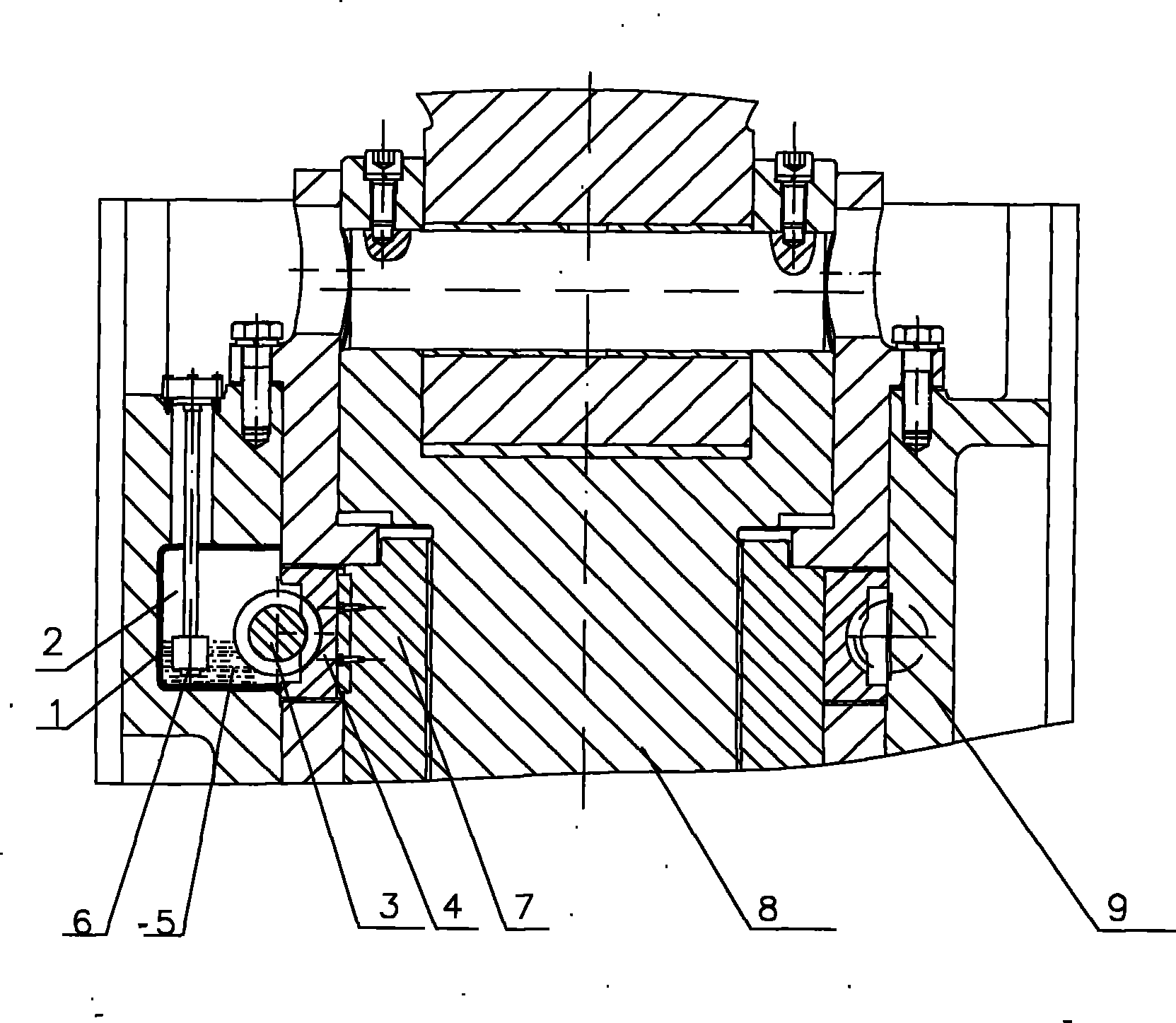

[0009] As shown in the accompanying drawings, the current press worm gear box includes a chamber body 2 surrounded by a worm gear case wall 1 and a worm screw 3 arranged in the chamber body, a worm wheel 4 and lubricating oil 6 contained in the chamber body.

[0010] During normal operation, the adjusting motor drives the worm screw 3 to rotate, and the worm wheel 4 engaged with the worm screw 3 drives the adjustment nut 7 to rotate through the key, and the adjustment nut 7 and the lifting screw 8 produce relative displacements to achieve the purpose of adjusting the height of the press slider 9. Since the sealing height adjustment of the press slider 9 is carried out through a series of transmissions, there must be enough lubricating oil for lubrication between the meshing parts. The lubricating oil 5 contained in the worm gear box is used for this purp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com