Seeding nozzle with self-cleaning and anti-blocking functions and seeding device with nozzle

A self-clearing and anti-blocking technology, which is applied in the field of seeding equipment and seeding nozzles, to achieve the effects of reducing energy use, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] First, a sowing nozzle with self-clearing and anti-clogging functions based on the technical solution of the present invention will be described.

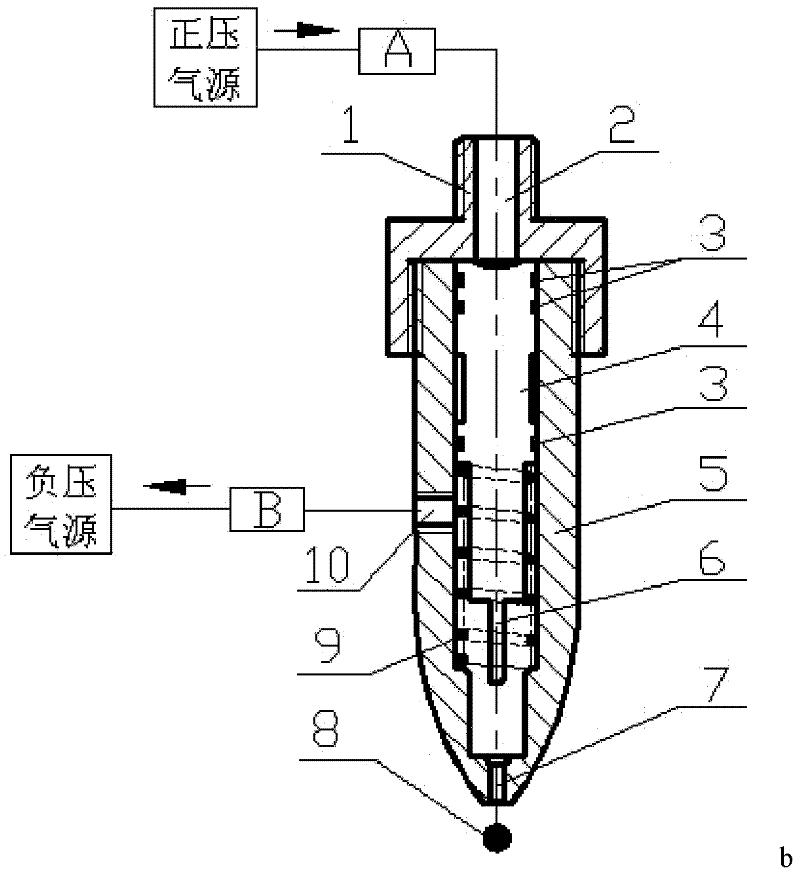

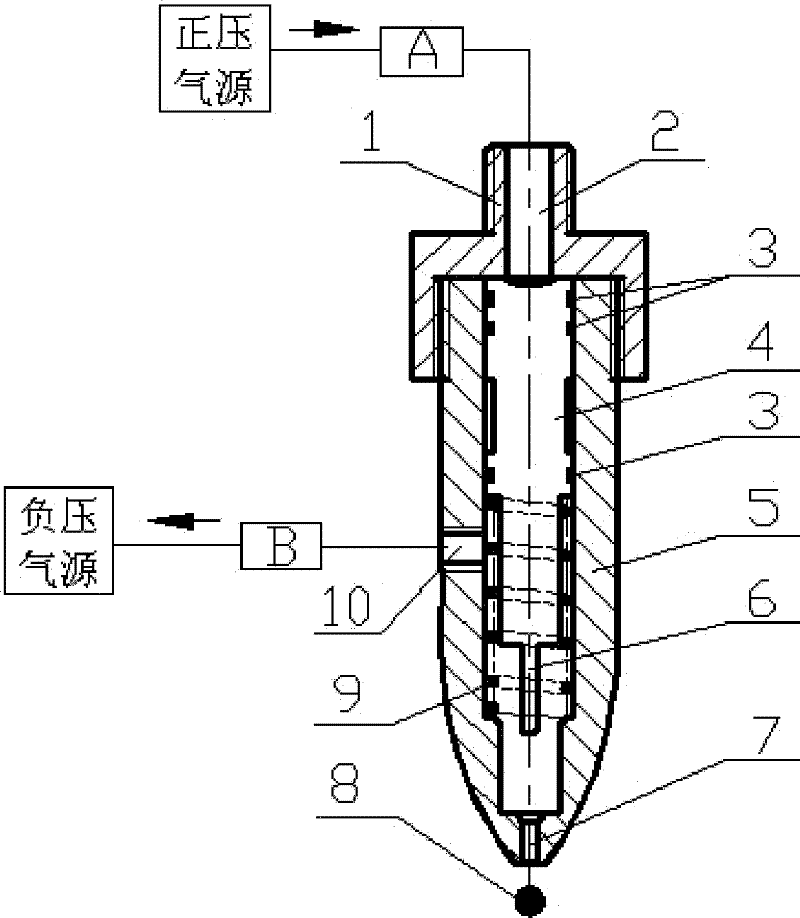

[0047] Such as figure 1 As shown, the sowing nozzle with self-clearing and anti-blocking function includes:

[0048] The nozzle head 5 has a circular hollow structure inside, one end is provided with an external thread, and the other end is provided with an adsorption hole 7, and the aperture of the adsorption hole 7 is set according to the size of the seeds to be sown;

[0049] Connecting block 1, the inside of which is set as a circular hollow structure, one end is provided with an internal thread to be threadedly connected with the nozzle head 5, and the outer surface of the other end is provided with an external thread for connecting an external support component for suction. Overall fixation of the mouth;

[0050] Return spring 9, which is a compression spring, is fixedly arranged on the inner surface of the inner cav...

Embodiment 2

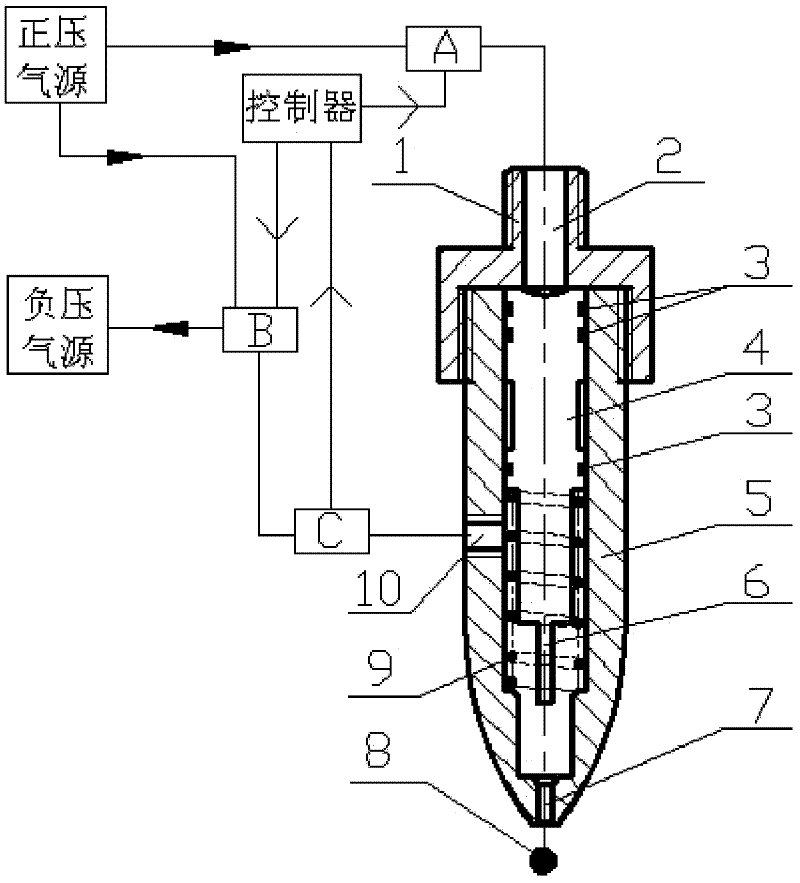

[0060] Next, the sowing equipment including the sowing suction nozzle described in the above-mentioned embodiment 1 based on the technical solution of the present invention will be described.

[0061] Such as figure 2 As shown, the sowing equipment includes: the aforementioned sowing suction nozzle with self-clearing and anti-blocking function, gas flow meter C, electromagnetic reversing valves A and B, and a controller.

[0062] Wherein, the structure of the sowing nozzle is the same as that provided in Example 1, and will not be repeated here;

[0063] Wherein, the second air inlet 10 of the nozzle head 5 communicates with the electromagnetic reversing valve B through the gas flowmeter C, and the electromagnetic reversing valve B is respectively connected with the positive pressure air source and the negative pressure air source; The reversing valve B is connected to and controlled by the controller, so that the second air inlet 10 is alternately connected to the negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com