Point pouring gate injection mould capable of automatically pushing out condensed materials

A point gate, injection mold technology, applied in the field of point gate injection mold, can solve the problems affecting the stability and reliability of the mechanism, high requirements for inclined holes, etc., to achieve the effect of compact mold, perfect function, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

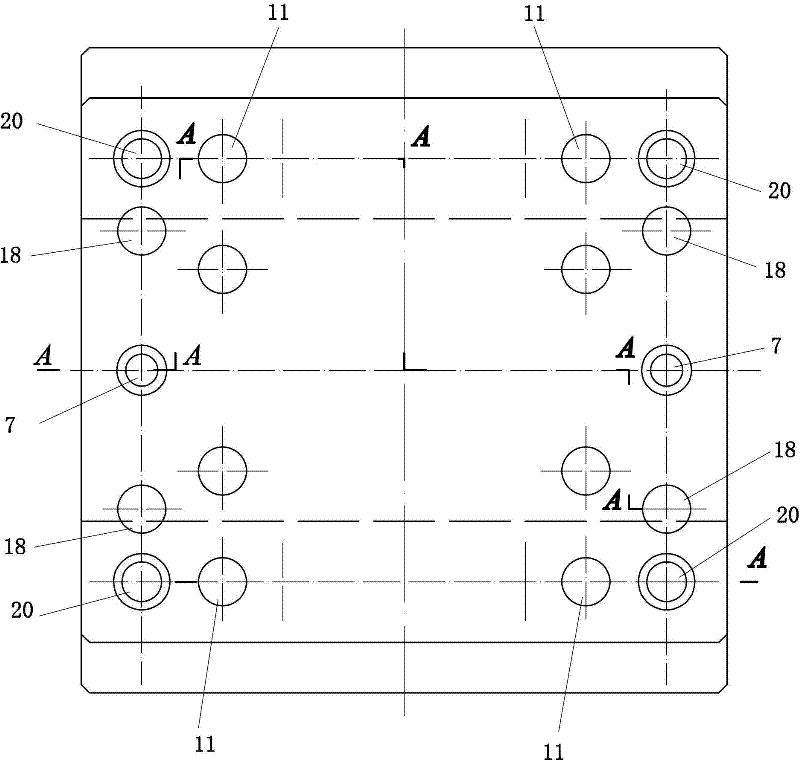

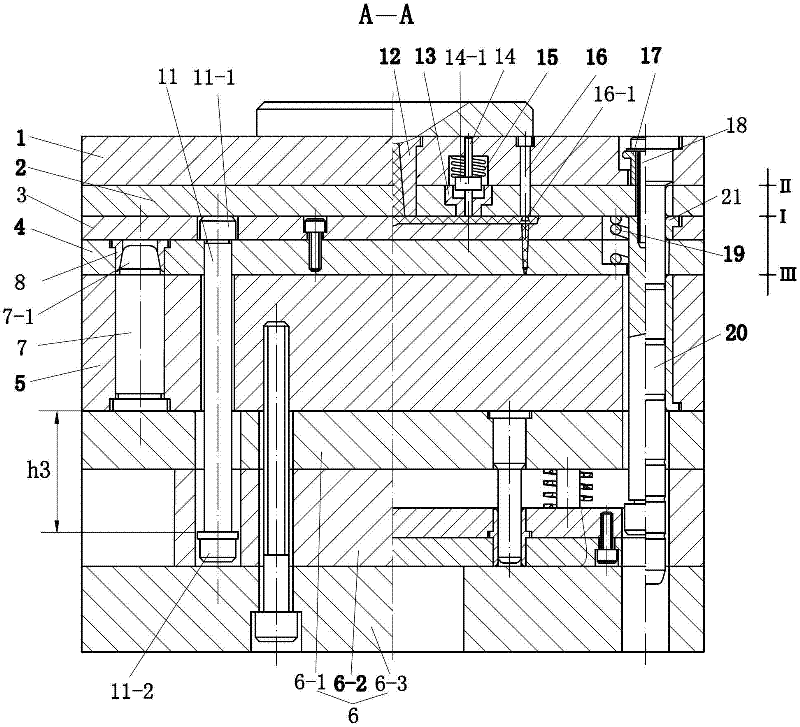

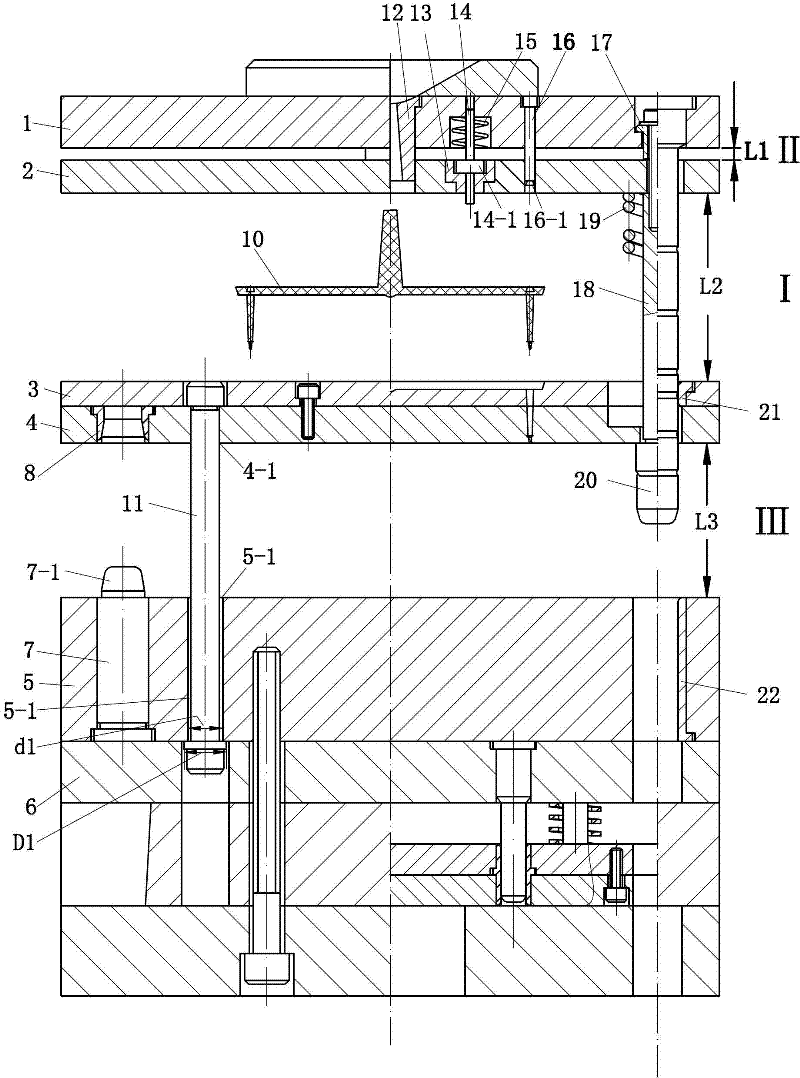

[0023] See attached Figures 1 to 7 , this embodiment includes a fixed mold seat plate 1, a de-gate plate 2, a runner plate 3, a fixed template 4, a movable template 5, and a movable mold seat 6 arranged in sequence from front to back, wherein the runner plate 3 and the fixed template 4 Connected together, movable template 4 and movable mold base 6 are connected together. Above-mentioned movable mold seat 6 is made up of movable mold backing plate 6-1, spacer 6-2 and movable mold base plate 6-3.

[0024] Between the fixed template 4 and the movable mold base 6, there are four first distance tie rods 11 connected by a hole shaft structure, and the first distance tie rods 11 are used to control the maximum parting distance between the fixed template 4 and the movable template 5 . Between the fixed mold base plate 1 and the movable mold base 6, there are four second distance tie rods 18 connected by a hole shaft structure, and the second distance distance tie rods 18 are used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com