Lift type pickup roller mechanism

A pick-up roller and lift-type technology, which is applied in the design and manufacture of printer equipment, can solve problems such as scratches and affect printing quality, achieve good results, improve printing quality, and have a reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

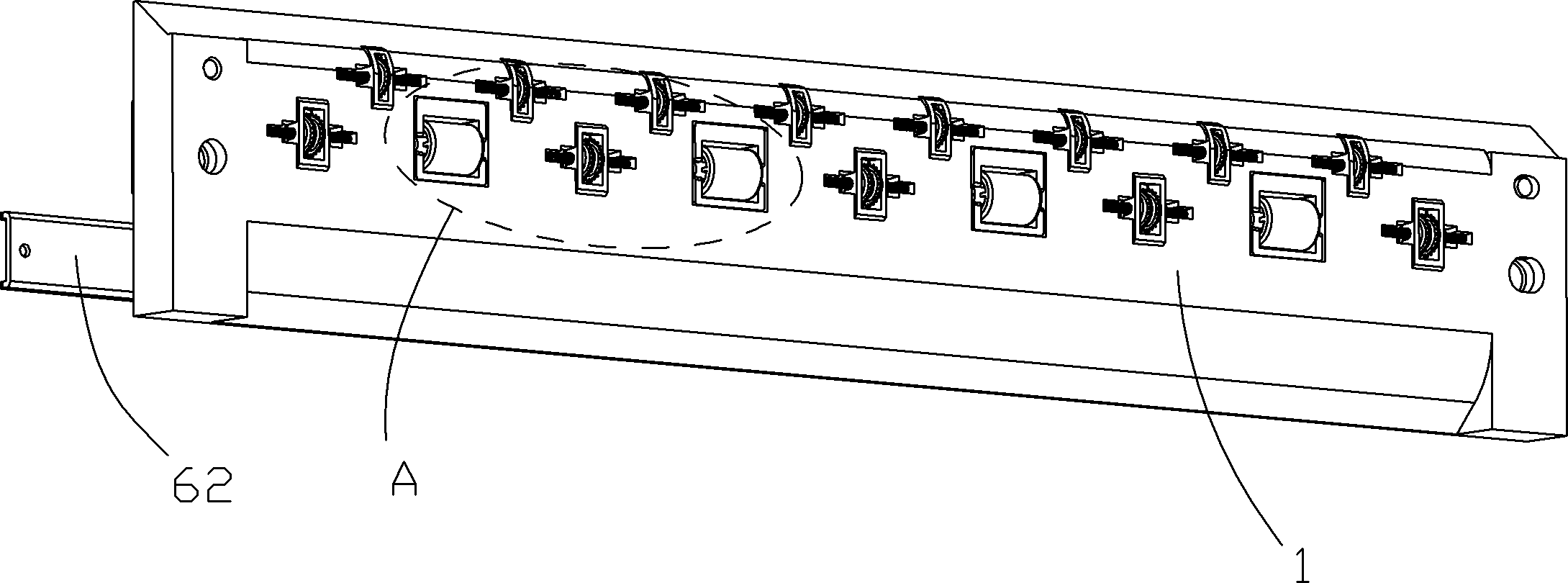

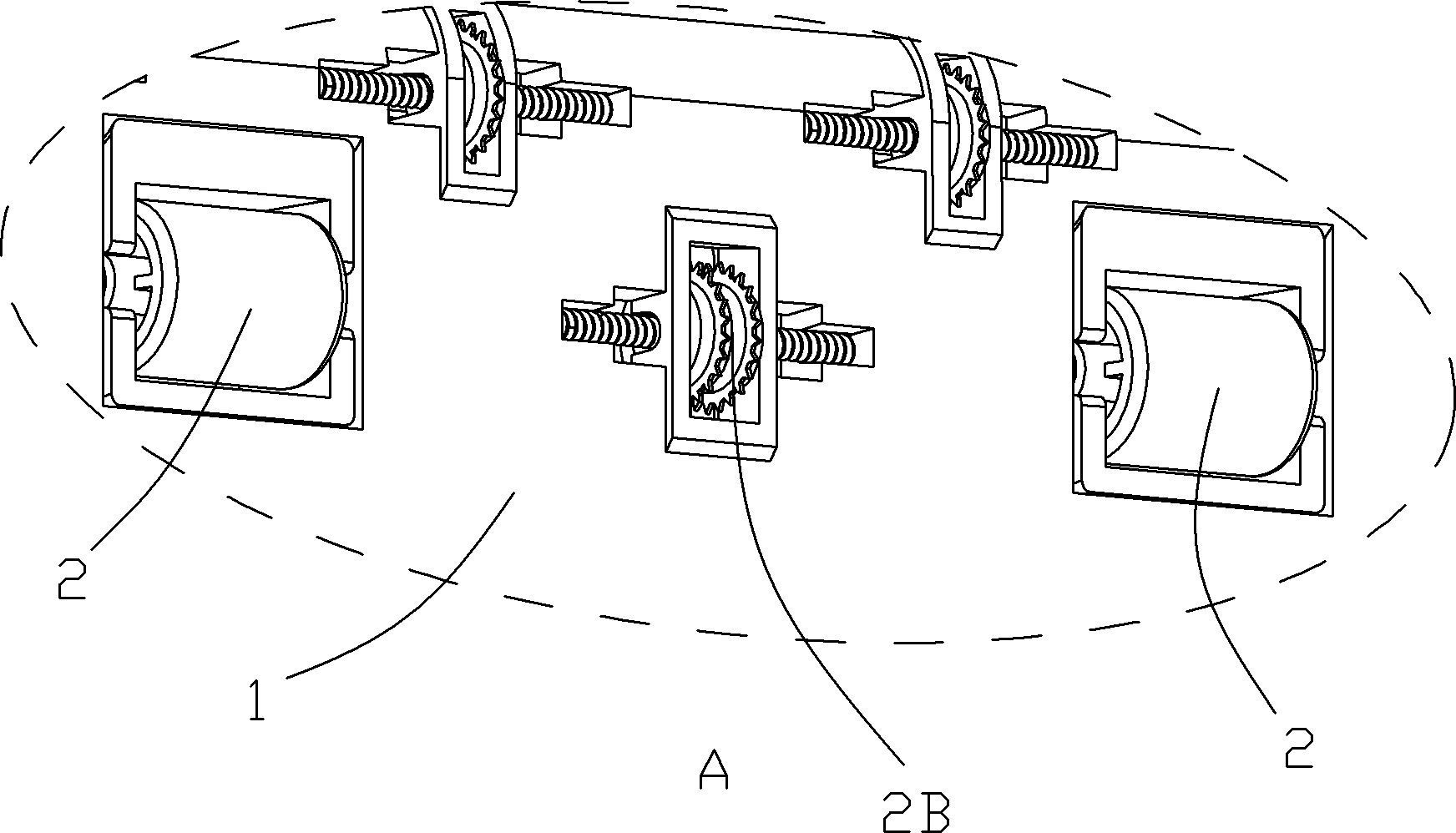

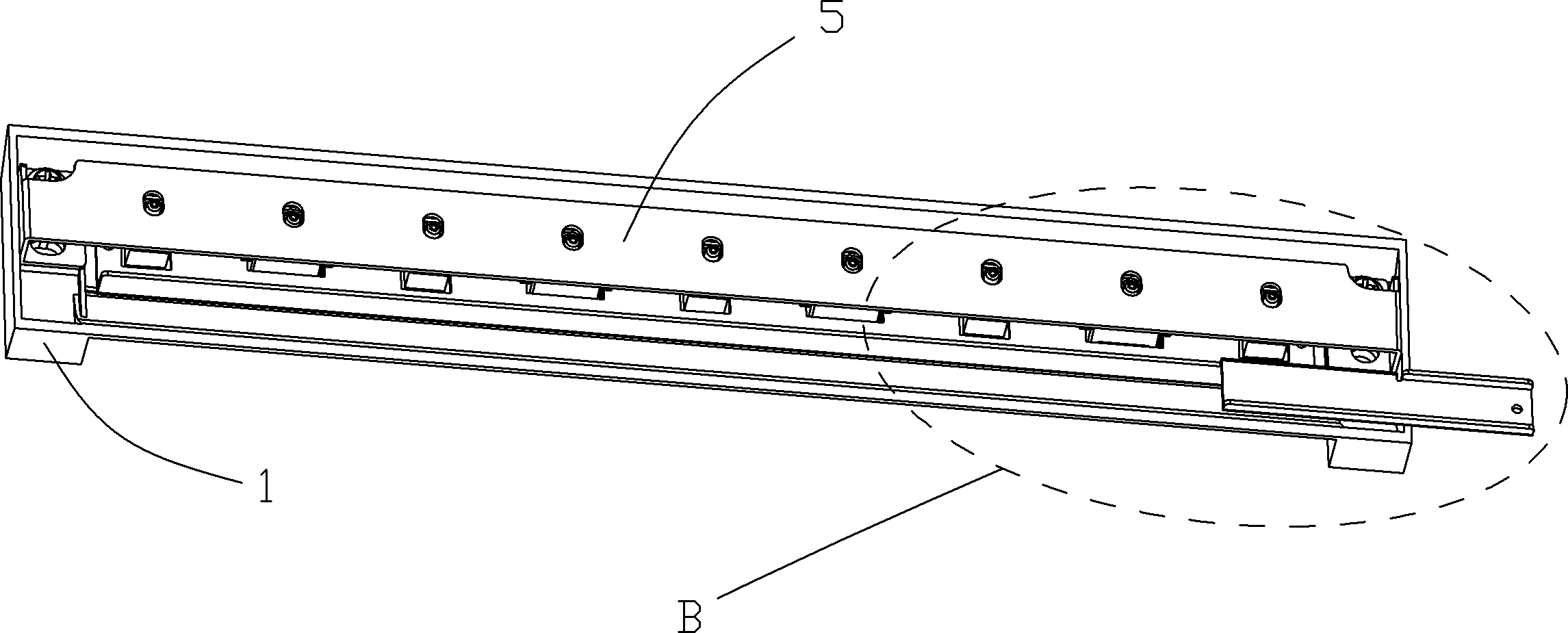

[0035] refer to Figure 1 to Figure 21 , a lifting type pickup roller mechanism of the present invention, which includes a pickup roller 2 installed on an upper paper guide base 1, the pickup roller 2 is rotatably connected to the bottom end of a pickup roller frame 3, and the pickup roller frame 3. Place it in the square hole 11 on the upper paper guide base 1. The top end of the pickup roller frame 3 is connected with a compression spring 4, and the other end of the compression spring 4 is connected to the upper paper guide base 1. The bottom end of the pressure plate 5, the pressure plate 5 is fixedly installed on the upper paper guide base 1 by screws 51, the upper paper guide base 1 is hinged with a top plate 6, considering that the thickness of the top plate 6 inside the printer is relatively thin, about 1mm Thickness, the top plate 6 is generally selected as a sheet metal part, and it is difficult to form a thick and long axis for hinges on the sheet metal part, so the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com