Automatic wallpaper gluing machine

A gluing machine and wallpaper technology, applied in coatings, devices for coating liquid on the surface, decorative arts, etc., can solve problems such as bad leakage and achieve high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

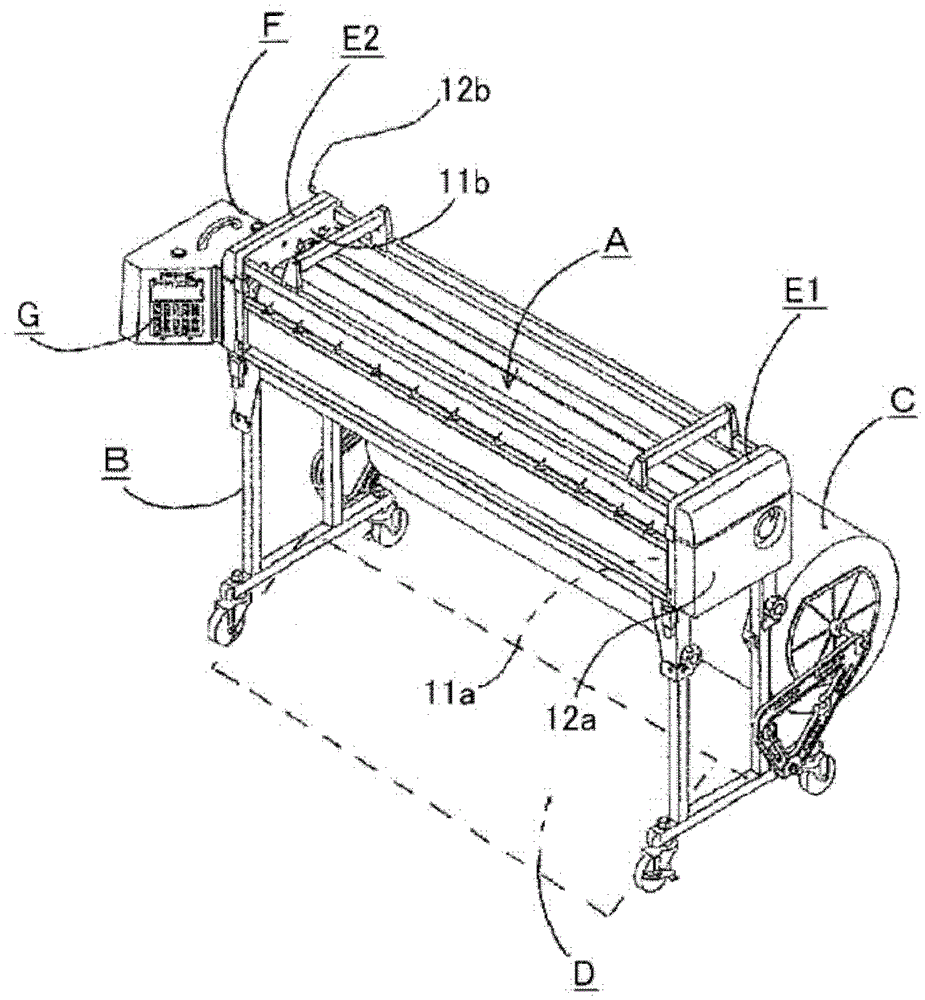

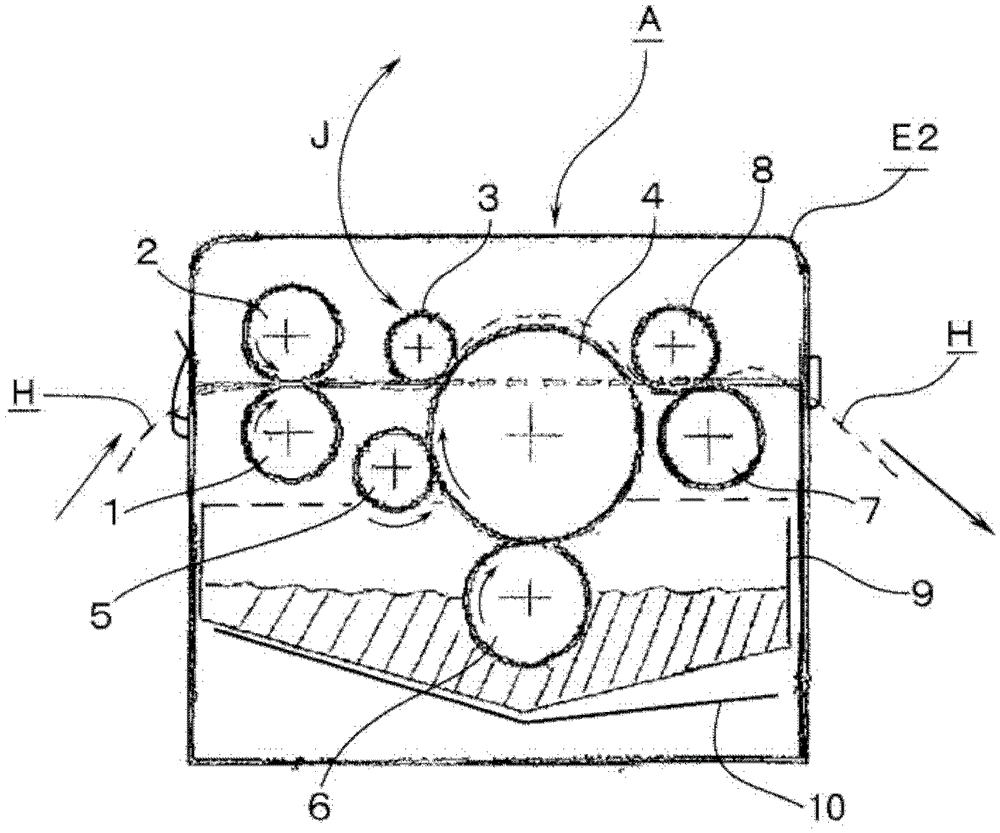

[0077] In the present invention, for example figure 1 , figure 2 The exemplified automatic wallpaper gluing machine applies glue to the back of a sheet-shaped wallpaper by the operation of a plurality of rollers including the above-mentioned gluing roller and glue amount adjusting roller.

[0078] Of course, if figure 1 As shown, the display / operation unit G and the drive unit F may be detachably attached as a box form, or may be in various conventional forms other than this.

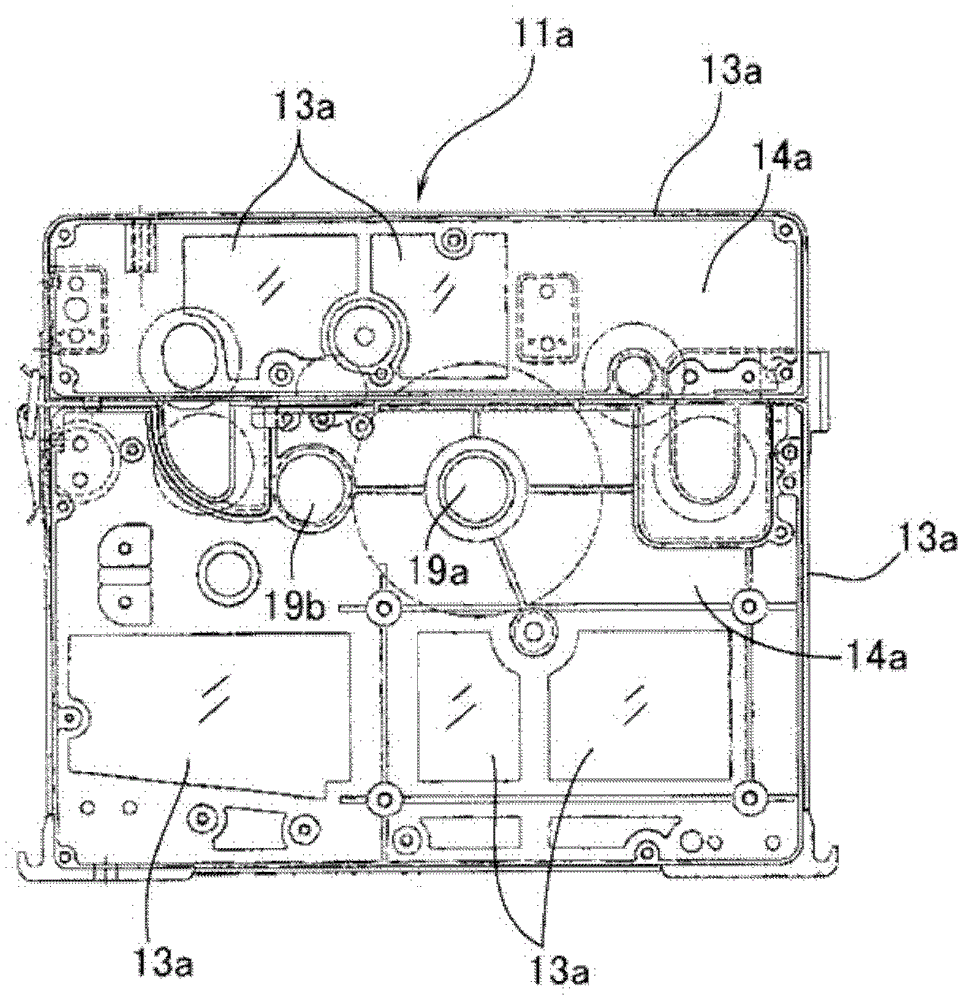

[0079] In the automatic wallpaper gluing machine of the present invention, for example figure 2 Illustrative example of bearing a plurality of rollers with both ends figure 1 In such a pair of frame side plate parts E1, E2, there are roller support plate parts 11a, 11b and resin cover parts 12a, 12b, and each roller support plate part 11a, 11b is a resin part and a metal part passing through the roller facing side. It is formed by the composite integration of the framework.

[0080] image 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com