Aligning lamination pressing machine of semi-automatic reinforcing sheet of flexible printed circuit board

A flexible printing and reinforcing sheet technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as low efficiency, slow production speed, and difficulty in ensuring product quality, and achieve the goal of ensuring product quality and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

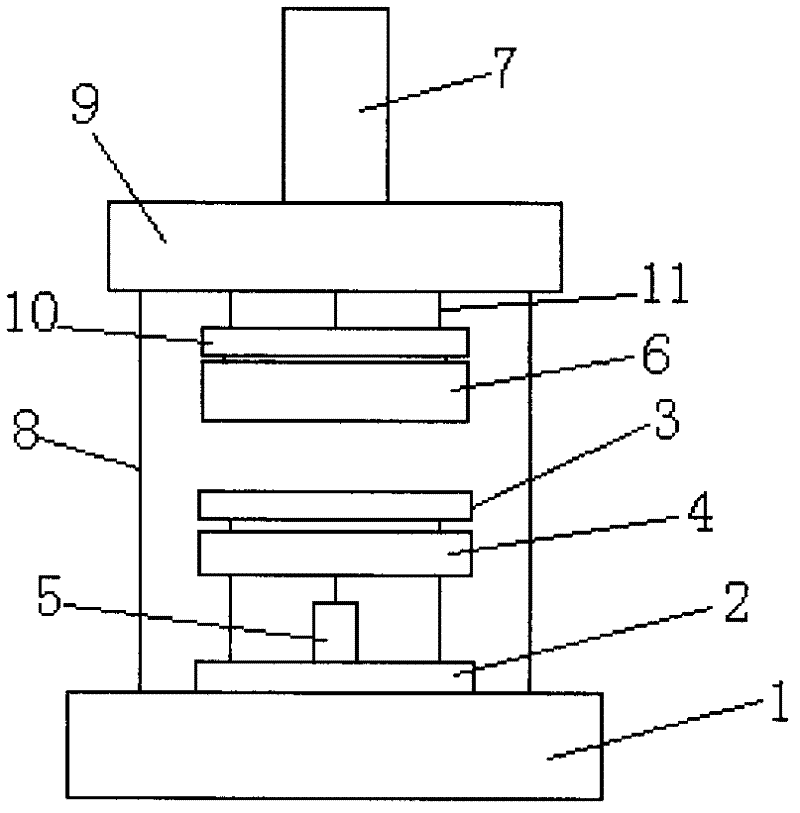

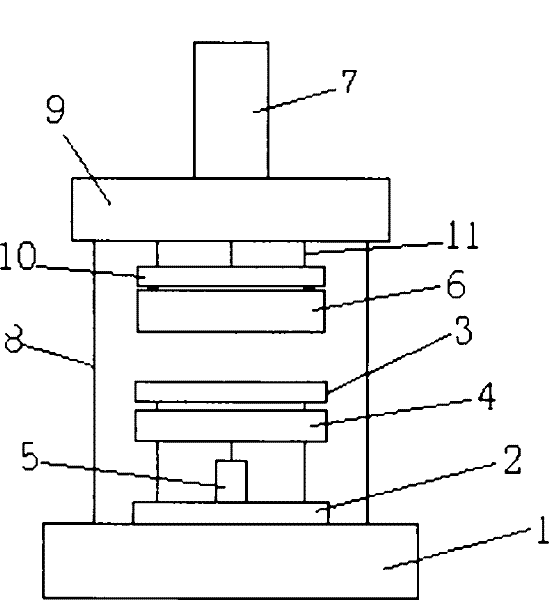

[0014] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0015] Reference figure 1 , A flexible printed circuit board semi-automatic reinforcing sheet alignment laminating machine, including a base 1, the base 1 has a movable mold, the movable mold includes a bottom plate 2, the bottom plate 2 is provided with upward extension The guide post, the upper end of the guide post is fixedly provided with a fixed template 3, the guide post is also provided with a movable template 4 located below the fixed template 3, and the bottom plate 2 is also provided with The mold cylinder 5 below the movable mold plate, and the piston rod of the mold cylinder 5 is connected with the movable mold plate 4;

[0016] The fixed template 3 is provided with a reinforcing sheet mold groove, the movable mold plate 4 is provided with a thimble, and the thimble corresponds to the reinforcing sheet mold groove and is extended into the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com