Tread profile of a pneumatic vehicle tire

A technology for pneumatic tires and vehicles, applied to tire treads/tread patterns, vehicle components, tire parts, etc., can solve problems such as limited bending stiffness and limited tire durability, and achieve fine classification, high support effect, The effect of high support area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

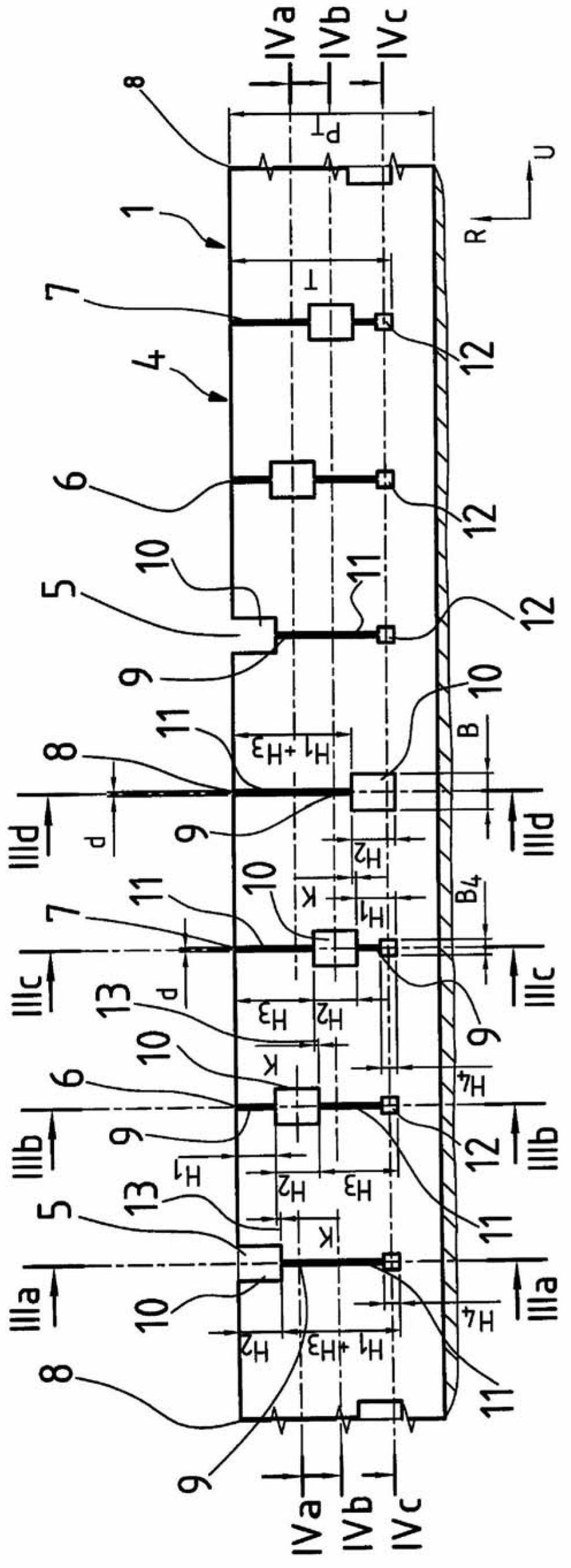

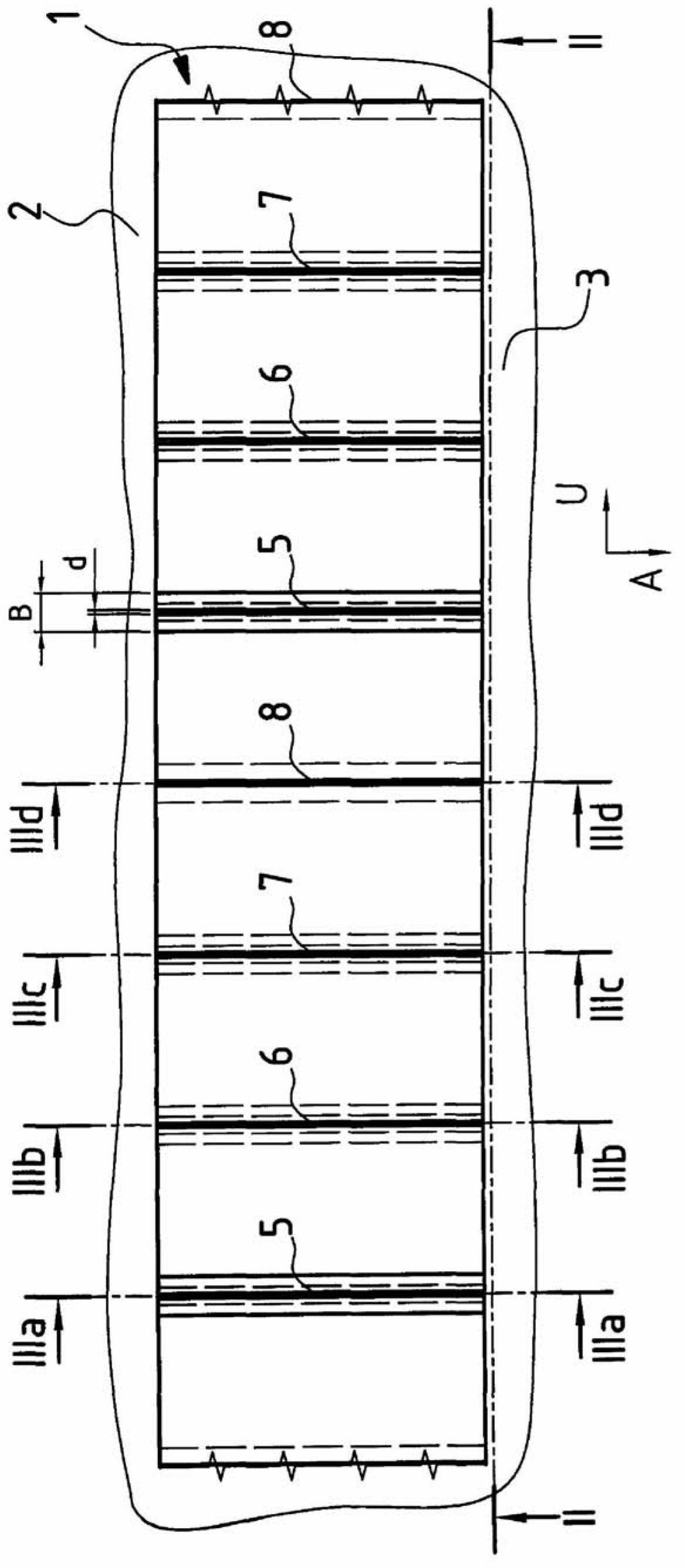

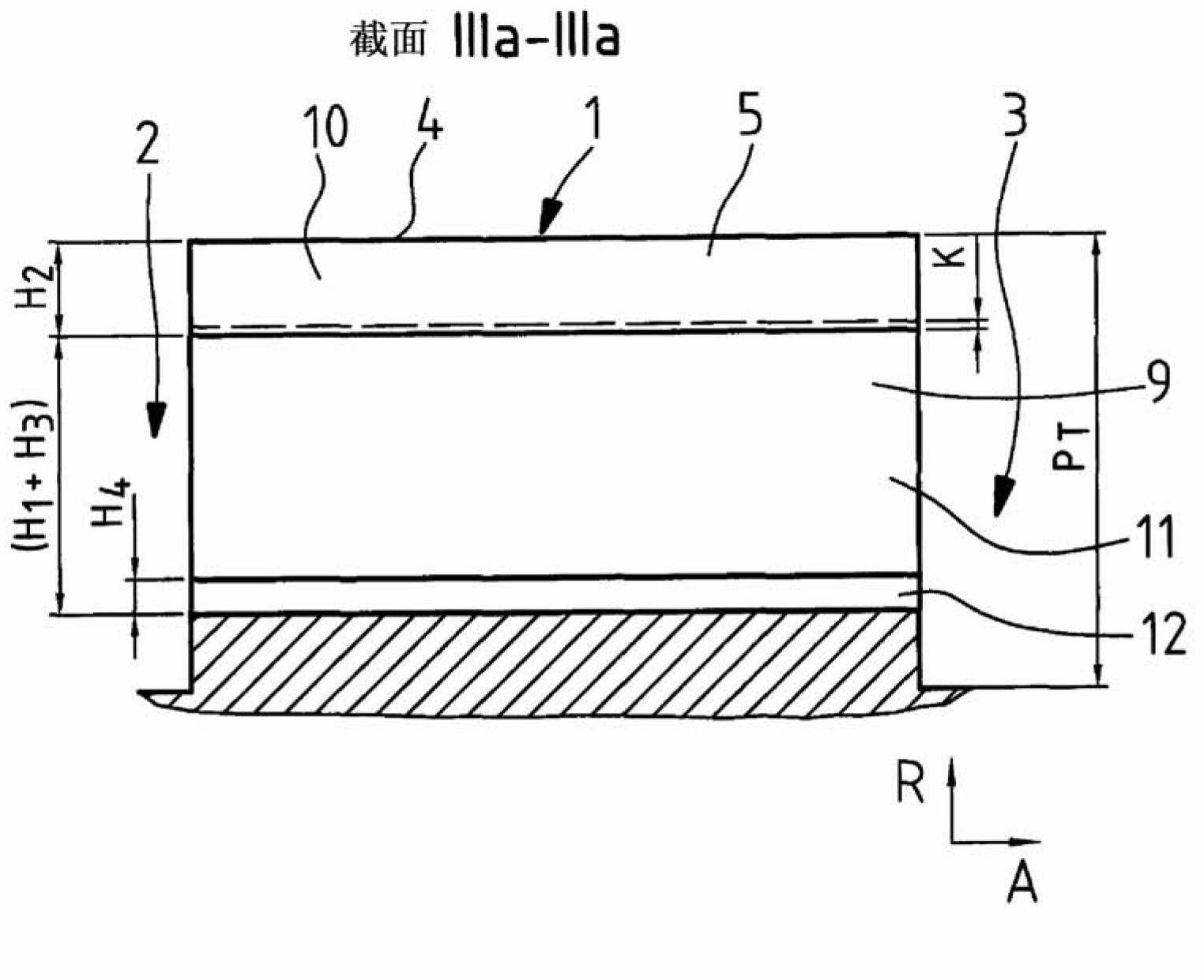

[0049] figure 1 , 2 , 3a, 3b, 3c and 3d show a circumferential rib 1 formed in the circumferential direction U of the pneumatic tire of a commercial vehicle, extending over the entire circumference of the pneumatic tire of the vehicle, and protruding in the radial direction R, the circumferential rib The vehicle pneumatic tire is delimited axially on both sides in the axial direction A by a circumferential groove 2 and 3 extending in the circumferential direction U over the entire circumference and oriented in the circumferential direction U. The circumferential rib 1 extends outward in radial direction R from the groove base of the circumferential grooves 2 and 3 and is delimited on its radially outward surface by a cover 4 which forms the ground contact surface. The circumferential grooves 2 and 3 have a maximum depth measured radially inwardly from the cover 4 to the base of said grooves, which corresponds to the tread depth P T .

[0050] Distributed in the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com