resin modifier

A resin modifier, active energy ray technology, used in coatings, pretreated surfaces, conductive coatings, etc., to achieve excellent transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

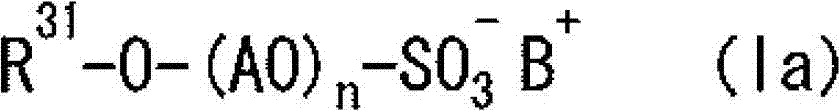

[0141] Hereinafter, examples and the like which specifically illustrate the present invention will be described. Examples 1 to 30 and Comparative Examples 1 to 20 are examples and comparative examples related to the compound (Ia). Examples 31 to 55 and Comparative Examples 21 to 39 are examples and comparative examples related to the compound (Ib). Examples 56 to 73 and Comparative Examples 40 to 55 are examples and comparative examples related to the compound (Ic). The evaluation items in Examples etc. were measured as follows.

[0142] [Preparation of resin modifier solution]

[0143] In this embodiment, first prepare the resin modifier solution, mix the prepared resin modifier solution, resin monomer, curing agent (UV initiator) and organic solvent, and manufacture Examples 1~73 and Comparative Examples 1~ 55 coating composition. However, for Examples 15-25, Examples 44-53, Examples 66-72, Comparative Examples 12-18, Comparative Examples 31-36, and Comparative Examples ...

manufacture example 1)

[0146] Put 500 g of aliphatic alcohol with 12 carbons (manufactured by Kao Corporation, product name: KALCOL 2098) and 0.75 g of KOH into an autoclave equipped with a stirring device, a temperature control device, and an automatic introduction device, and heat at 110°C and 13hPa Dehydrate for 30 minutes. Nitrogen replacement was carried out after dehydration, and after heating to 120°C, 355g of ethylene oxide (EO) was charged. Addition reaction and aging were performed at 120° C. for 4 hours, then cooled to 80° C., and unreacted EO was removed at 40 hPa for 30 minutes. After removing unreacted EO, 0.8 g of acetic acid was added to the autoclave, stirred at 80° C. for 30 minutes, and then extracted to obtain an alkoxylate having an average added mole number of EO of 3 moles.

[0147] Use SO 3 gas, using a falling film reactor to sulfate the obtained alkoxylate to obtain a poly(3) oxyethylene lauryl ether sulfate composition. 100 g of the composition (A) was dropped into 322 ...

manufacture example 2)

[0149] Poly( 17) An aqueous solution of sodium oxyethylene lauryl ether sulfate (25% by weight of the active ingredient).

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com