Tightening edge connecting structure, underwear using structure, and processing technology

A technology for connecting structure and underwear, applied in the direction of underwear, application, clothing, etc., can solve the problems of unreasonable design of tightening edge, insufficient warmth retention, overall stiffness, etc., to achieve beautiful clothes, improve thermal insulation effect, and good comfort. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

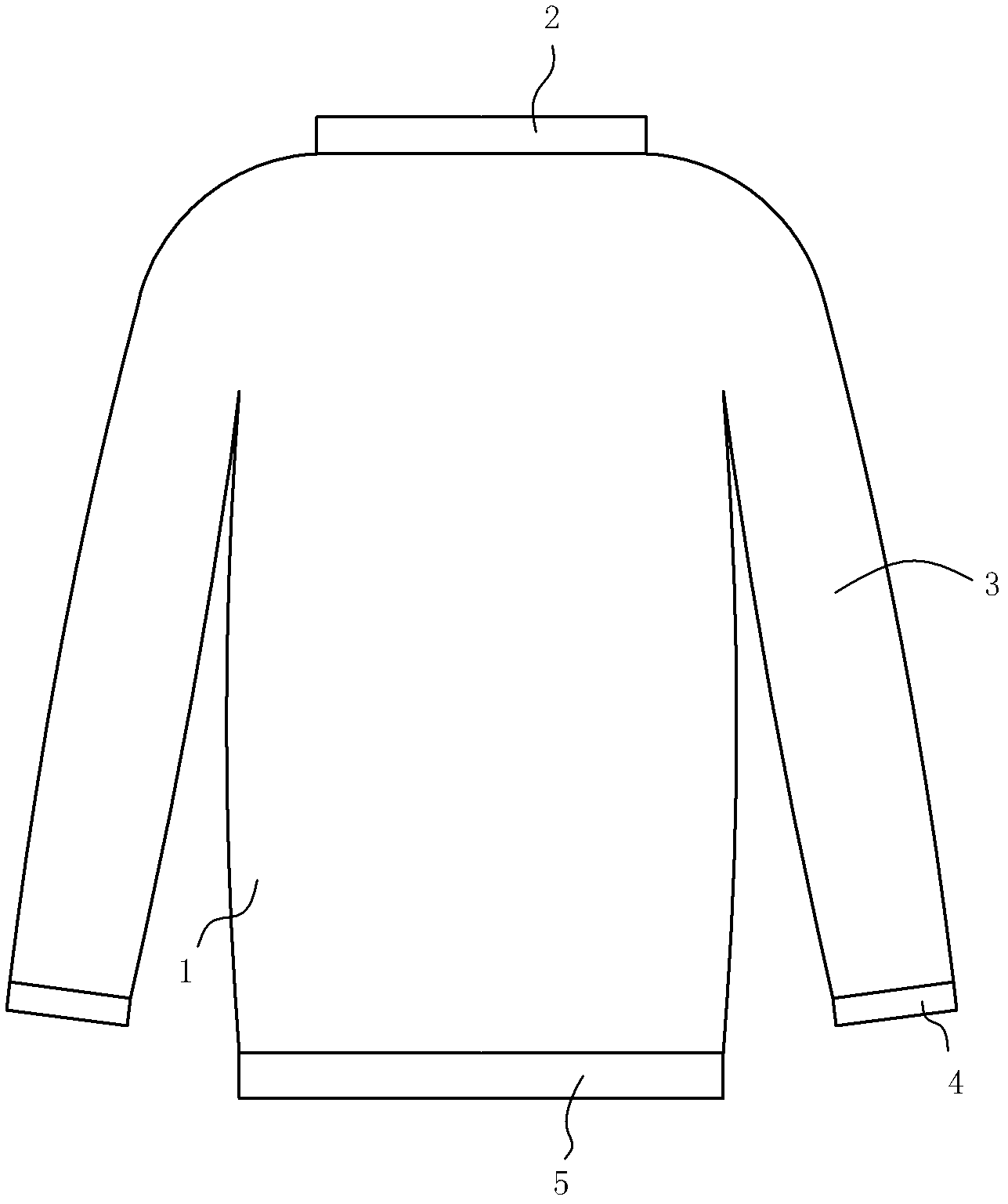

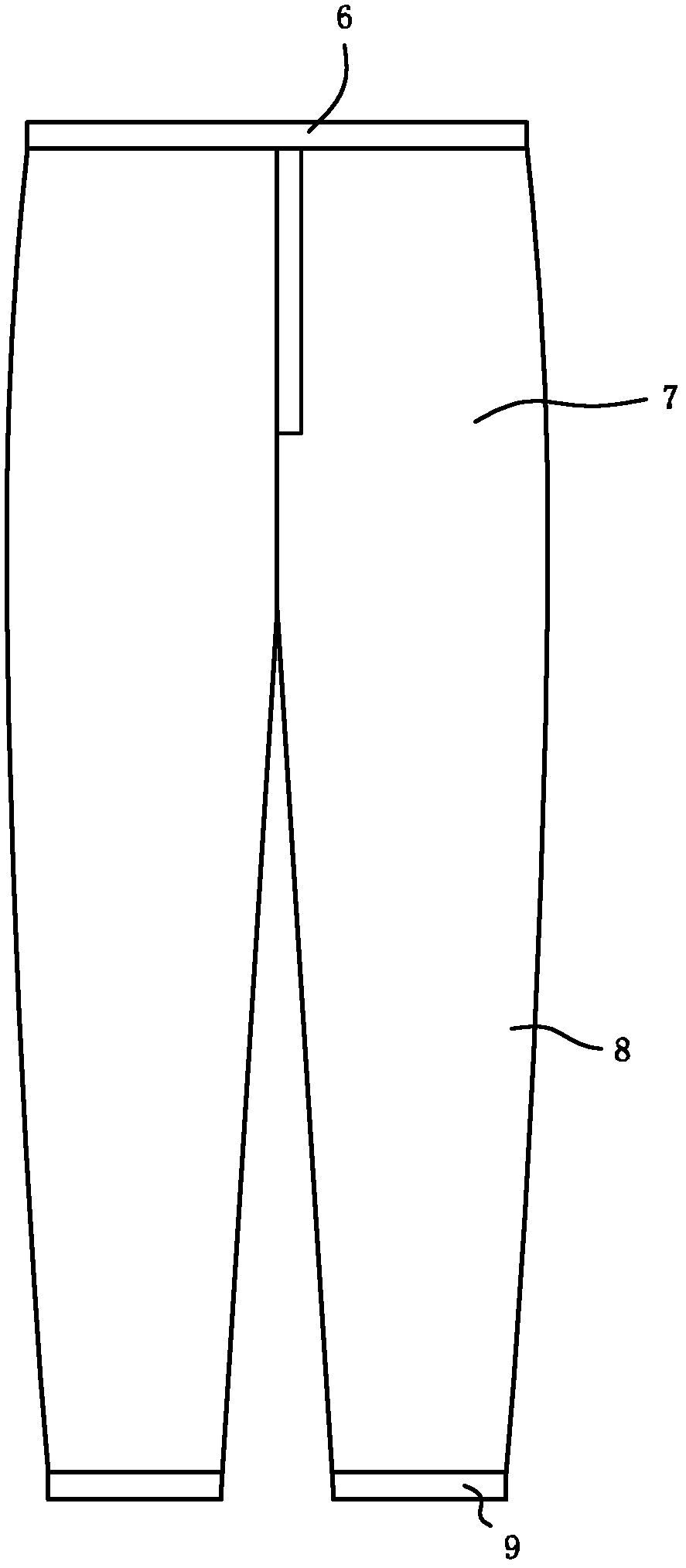

[0031] refer to figure 1 , 2 , common underwear, including tops and long underpants, the tops include a body 1, sleeves 3, the upper end of the body is connected to the neckline 2, the lower port is connected to the hem 5, and the lower end of the sleeves 3 is connected to the cuff 4; Described long underwear comprises crotch 7, trousers leg 8, and described trousers crotch upper end is connected with trousers waist 6, and described trousers leg 8 is connected below the trousers crotch 7, and trousers leg 8 lower end is connected with foot opening 9.

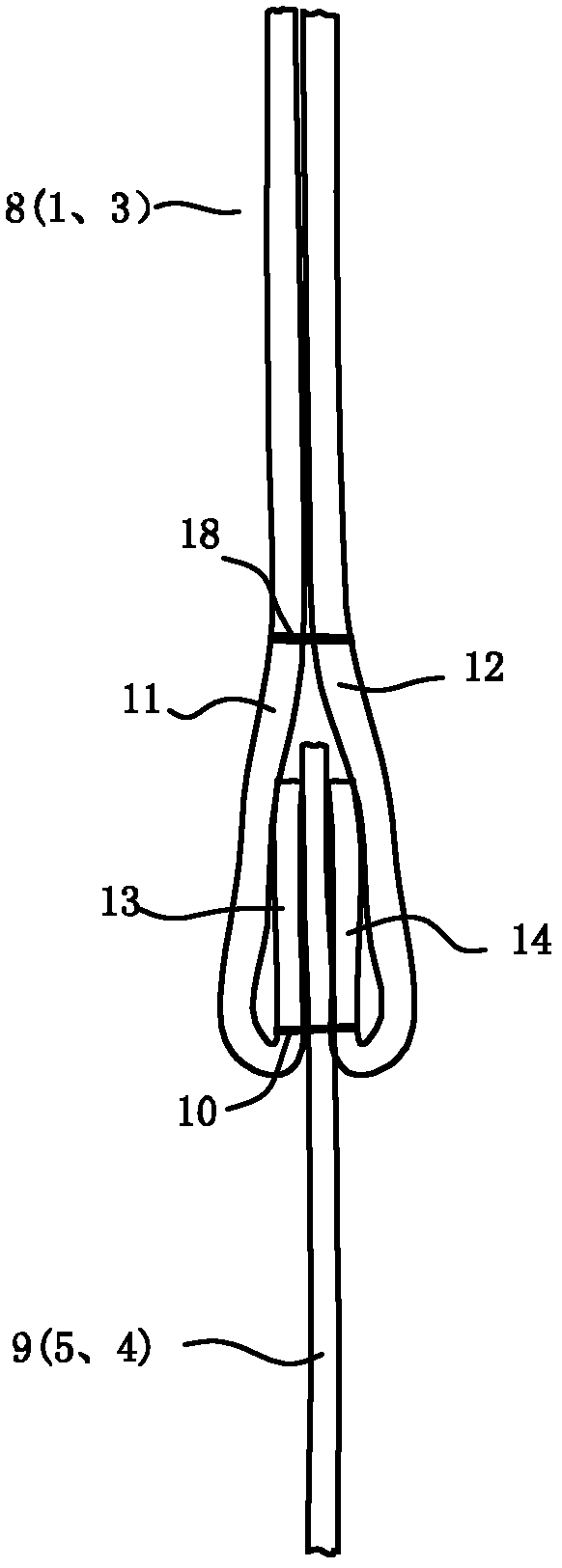

[0032] In the double-layer thermal underwear, main parts such as its body 1, sleeves 3, crotch 7, trouser legs 8 are all made of double-layer fabrics. image 3 Shown is the connection structure between the existing double-layer thermal underwear body 1 and hem 5, sleeves 3 and cuffs 4, trouser legs 8 and foot openings 9. Taking the connection between the trouser leg and the foot opening as an example, the specific connection p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com