Anti-mine composite structure armored vehicle for carrying out multi-angle shunting on detonation waves

A composite structure, detonation wave technology, applied in armored vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of impact damage, structural deformation, insufficient anti-knock strength of single-layer materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

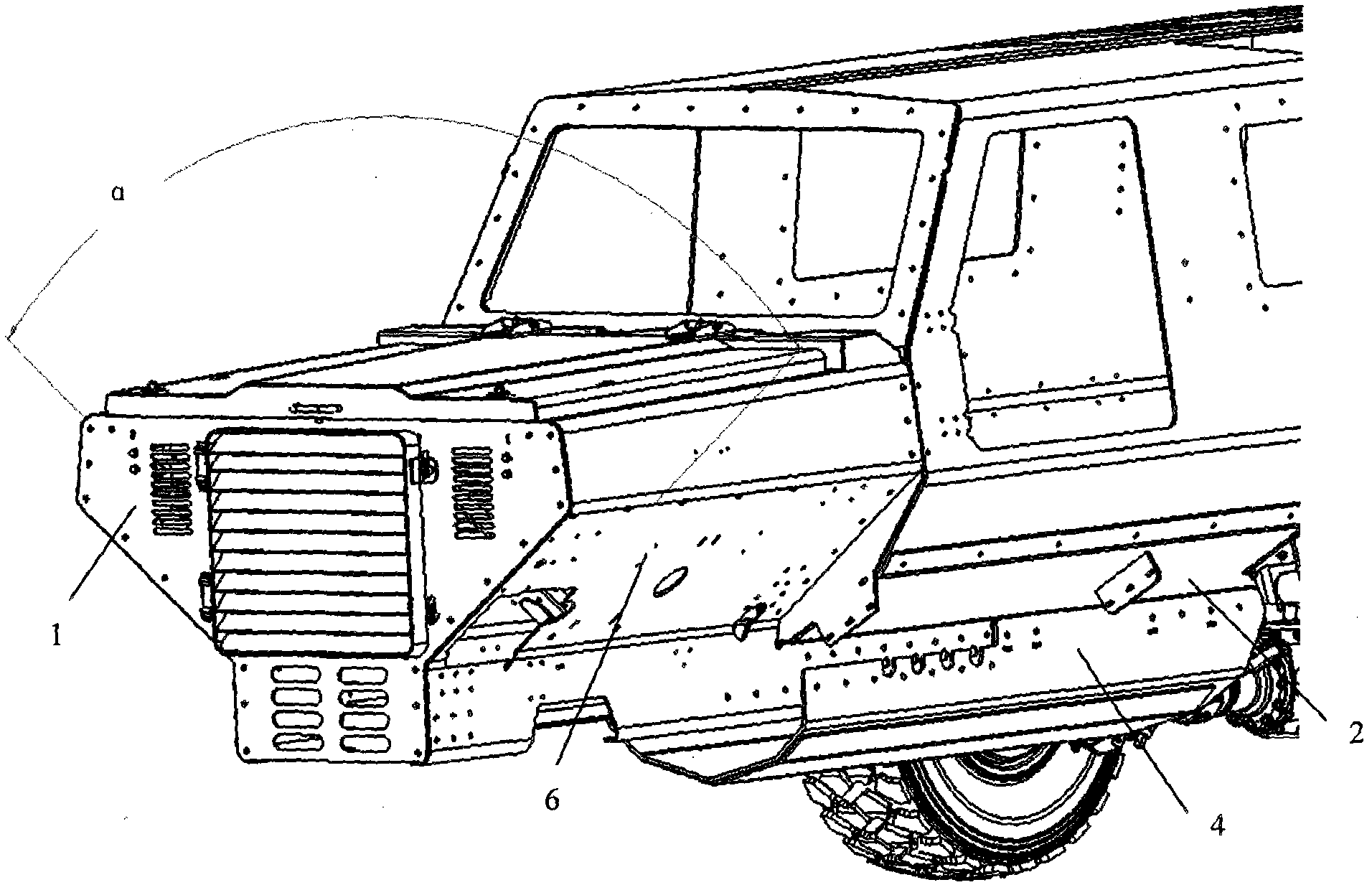

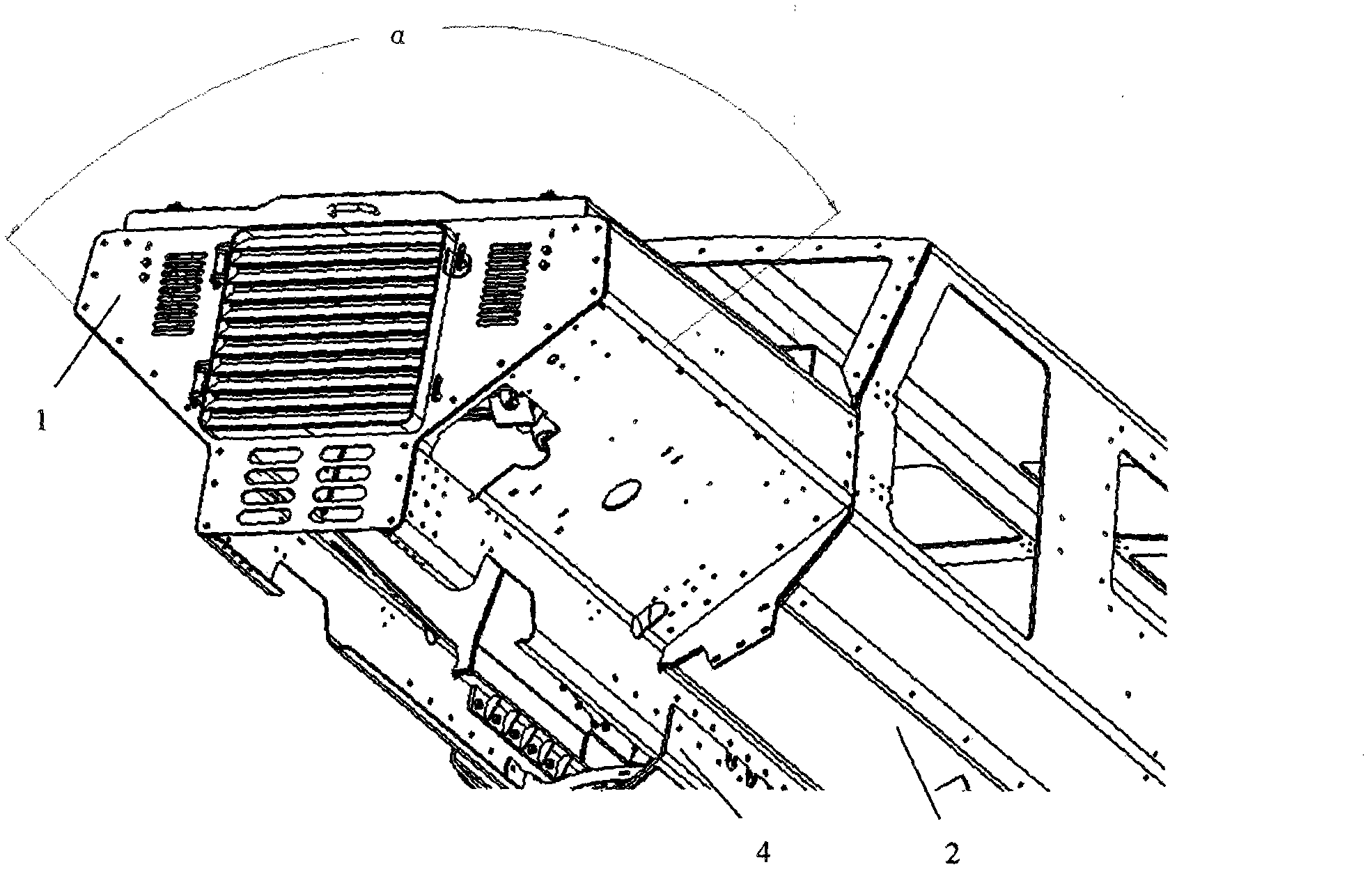

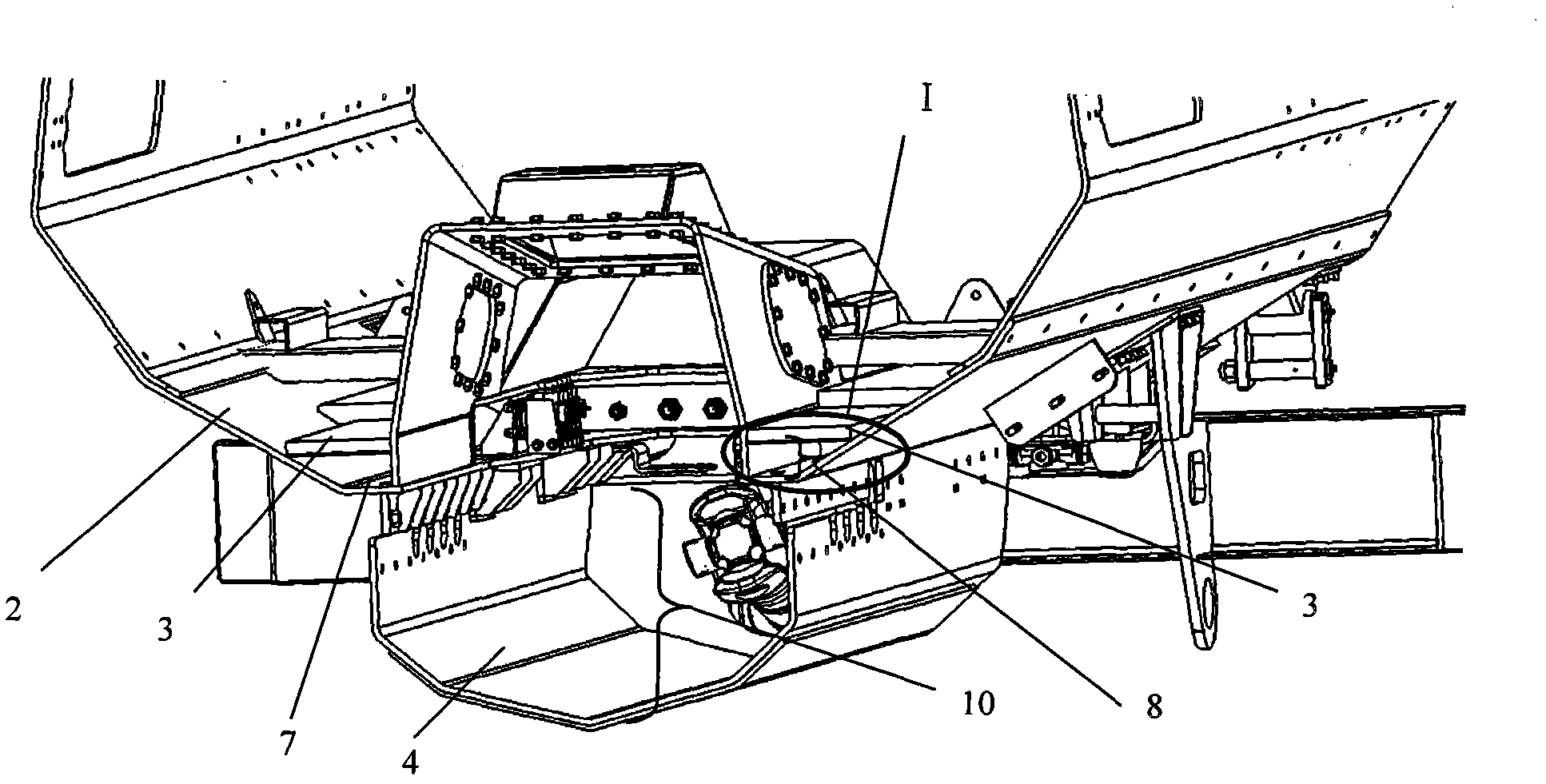

[0019] Such as Figure 1-8 As shown, the present invention is an armored vehicle with a multi-angle shunt detonation wave lightning protection composite structure, including a vehicle head 1, a vehicle body chassis 2 connected to the vehicle head, a passenger floor 3, and a continuous V-shaped structure located below the vehicle body chassis and close to the vehicle head. The protective cover 4 and the protective plate 5 located near the rear of the vehicle under the chassis, the front of the car includes two decks 6, which are symmetrically installed, and the angle α is 100°±10°, and the bottom of the front 1 is an open structure.

[0020] Both sides of the body chassis 2 are in two continuous V-shaped structures, and the V-shaped angle β is 130-160°. There is a gap between the bottom deck 7 of the body chassis 2 and the occupant floor 3, forming the second buffer space 8, and the occupants Flexible non-metallic materials 11 are compounded on the floor 3 .

[0021] The conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com