Automatic leading wire inserting device for paper tube

A guiding device and paper tube technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of low safety, long production cycle, low production efficiency, etc., and achieve accurate insertion position, insertion quality assurance, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

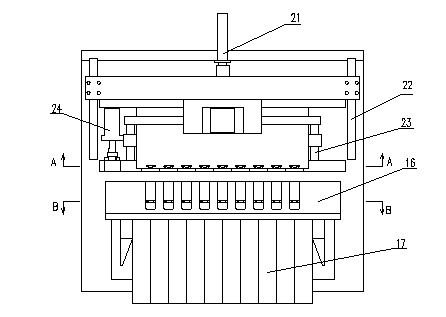

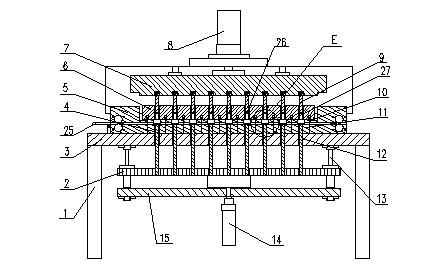

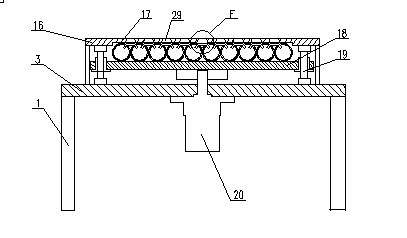

[0020] In the figure, the automatic insertion and introduction device includes a frame 1, a support plate 3, a guide device, a lead wire cutting and molding device and a moving device, the support is fixedly arranged on the frame, and the guide device includes a fixed On the support plate, a guide template 16 with a corresponding arc surface of the paper tube and a positioning plate 18 that is arranged below the guide template and installed on the positioning slide bar 19 can be driven by the positioning cylinder 20 to move up and down on the positioning slide bar. , the upper and lower ends of the positioning slide bar are respectively fixed on the guide template and the support plate, and the guide template is provided with guide holes 29 that can insert the forming lead 26 into two adjacent paper tubes 17 on the positioning plate; The lead wire slitting and forming device includes a cutting knife 10, a fixed lead plate 6, a threading block 11, an inserting lead bar 9 and a e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com